Business Sectors

Events

Offshore Support Journal Conference, Middle East 2025

Contents

Register to read more articles.

IMO updates pilot transfer arrangements to improve safety

Uzmar marine pilot Captain Mustafa Sokukcu summarises the changes IMO’s Maritime Safety Committee made to regulations concerning equipment for pilot transfers to ships

Important decisions were taken at the 110th meeting of the Maritime Safety Committee (MSC 110) of IMO, held between 18-27 June 2025. Specifically for pilot transfer arrangements, amendments to SOLAS chapter 5 regulation 23 and the performance standards for pilot transfer arrangements have been adopted.

These significant amendments, which aim to enhance the safety of all stakeholders using the transfer arrangements - especially pilots - were approved at the IMO (MSC 109) meeting in December 2024 with the support of national delegations and the International Maritime Pilots’ Association, and were adopted by MSC 110 in June 2025.

With these accepted updates, mandatory performance standards were added for the design, production, construction and installation of pilot transfer arrangements to SOLAS Chapter 5.

In addition, regulatory articles have been added regarding regular inspection, stowage, maintenance, equipment replacement and crew training for all transfer arrangements, while aspects of the updated performance standards concern equipment manufacturers.

The regulations are mainly aimed at maritime pilots who will mostly use the transfer arrangements. However, a safe arrangement regulation will also protect the lives of port authority employees, surveyor company employees and ship crew joining or leaving the ship who will use the transfer equipment.

For this reason, it is vital that transfer equipment is properly stored on board and prepared in accordance with the regulations. Maritime pilots’ right to inform the ship’s captain of unsafe transfer arrangements and to refuse to use them until the arrangement is made safe is clearly emphasised in SOLAS with the new updates.

Since the SOLAS convention is legally binding for IMO member states, all member states are required to harmonise their national laws according to these changes.

Although the new regulations will become mandatory after 1 January 2028, IMO recommends early voluntary implementation. Flag states’ preparation for the new amendments, by showing the necessary sensitivity without waiting for the compliance deadline, will contribute to the safety of human transfers at sea.

Regulation updates are required for all ships subject to SOLAS as of 1 January 2028, regardless of the date of equipping the transfer arrangements.

Service life has been defined for pilot ladders at a maximum of 36 months from the date of manufacture and 30 months from the date these are put into service on a ship.

In addition, it is mandatory to have a spare pilot ladder and ropes on board, for manufacturers to provide ships with information about the transfer equipment, and recommendations on maintenance, handling, control and storage on board. Furthermore, it is prohibited to repair pilot ladder steps on board the ship and to continue using the ladder by replacing damaged steps.

Certificates for all equipment used in pilot transfers, as well as records of inspections conducted on board, must be kept in a file and made available on board. Transfer equipment must be inspected by a responsible officer before each use, after each use, and every three months. Training should be provided to ship’s crew on regular inspections of transfer equipment, their stowage on board, maintenance and replacement at appropriate intervals.

With the accepted updates, mandatory performance standards have been added for the design, production, construction and installation of pilot transfer arrangements to SOLAS Chapter 5. In addition, regulatory articles have been added regarding regular inspection, stowage, maintenance, periodic replacement of equipment and training ship’s crew for all transfer arrangements.

It is worth emphasising that the new updates do not only concern pilots and ship’s crew, but also contain important issues that concern shipowners, ship operating companies, shipyards and equipment manufacturers. In particular, there are items within Part F of the performance standards that concern equipment manufacturers.

All vessels subject to SOLAS and equipped with pilot transfer arrangements before 2028 will need to be compliant with the new updates from their first class survey carried out after 1 January 2029. For vessels not subject to SOLAS, compliance will be required by October 2030.

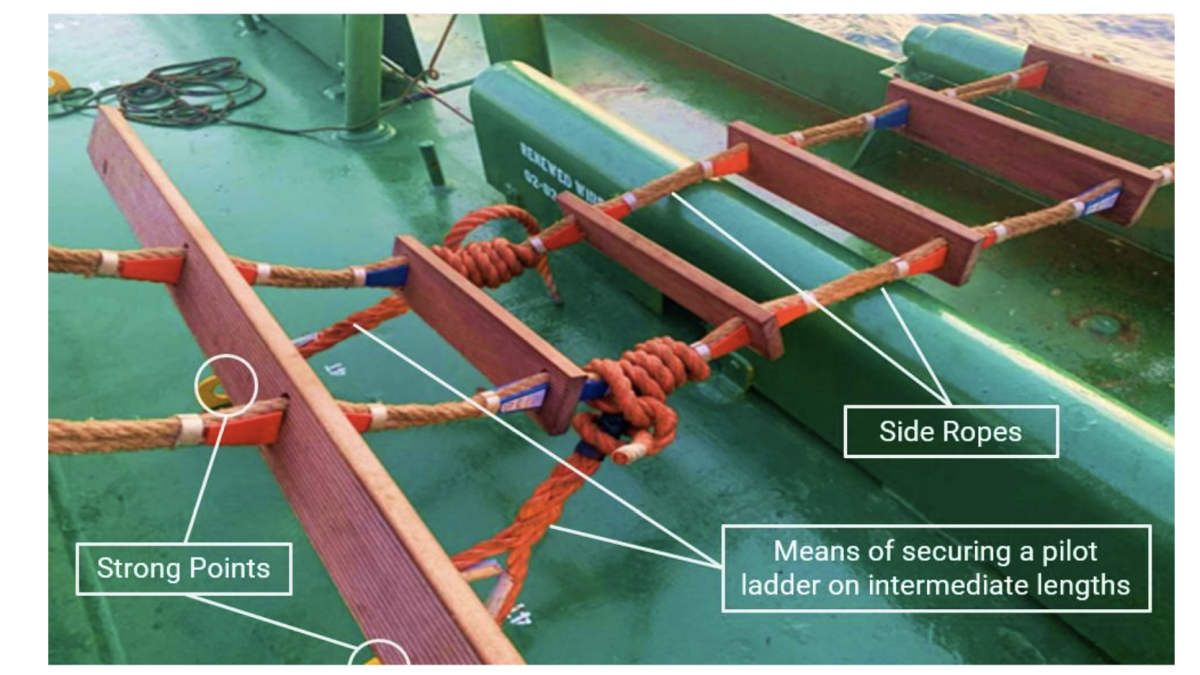

All transfer equipment, strong points and shackles should have breaking strength or equivalent safe working load clearly and permanently marked, while the minimum breaking strength required for strong points, shackles and ropes used to secure the pilot ladder on deck has been doubled from 24 kN to 48 kN.

The requirement for a maximum of nine steps between two spreaders has been changed to a maximum of eight steps with the new update. The thickness criteria for pilot ladder side ropes has been changed so the diameter of the side ropes must not be less than 20 mm and not more than 22 mm (the old rules mandated the thickness of the side ropes be a minimum of 18 mm).

When combined transfer arrangements are prepared, equipment used to fix the pilot ladder and the lower platform of the accommodation ladder to the ship’s side, known as magnets, must be capable of being safely attached and removed by a single crew member. In addition, magnets used to fix the accommodation ladder to the ship’s side must have a minimum holding capacity of 4 kN, and magnets used to fix the pilot ladder must have a minimum holding capacity of 3 kN.

"Manufacturers will be required to permanently mark the first step of the pilot ladder and the last spreader step with the ladder’s identifying information"

Pilot ladders, man ropes, spare transfer equipment and magnets must be included in the equipment list of the Ship Safety Equipment Certificate.

The existing provision prohibiting side doors used for pilot transfer from opening outwards has been amended to apply only to those located above the freeboard deck. Side doors located on bulkhead deck for pilot transfer are now permitted to open outwards.

Manufacturers will be required to permanently mark the first step of the pilot ladder and the last spreader step with the ladder’s identifying information.

They are required to produce type-approved devices to secure pilot ladders at intermediate lengths to strong points on deck. Until these devices are produced, the most suitable method of securing the pilot ladder to a strong point is by using 3-m rope slings with a breaking strength of 48 kN and a rolling hitch knot into the side ropes.

Strong points on deck must be at least 91.5 cm inside from the ship’s side plate and must not obstruct the transfer area. If this distance is not applicable for small vessels, the maximum allowed distance is expected to be provided. With the new updates, confusion regarding non-compliant trapdoor arrangements has been resolved and non-compliant trapdoor arrangements are strictly prohibited.

Securing pilot ladders

It is very important that pilot ladders are safely secured on the ship’s deck, as failure to secure the pilot ladder on deck was found to be a major factor causing pilot transfer accidents*.

While pilot ladders are being produced, the ends that will remain on the ship’s deck are knitted with a frame containing a thimble inside, and in cases where the full length of the pilot ladder is to be used, these points can be connected to strong points on the deck by using shackles.

However, in practice, the length of the pilot ladder often needs to be shortened, the ladder length needs to be adjusted from intermediate length and secured by tying it to a strong point on the ship’s deck.

In this securing process using shackles, the ladder’s own weight and the weight of the person on it can cause serious damage to the ladder arrangements, reducing the strength of the parts and increasing accident risks. Studies have been carried out in the maritime community for many years on this securing method, which we now call old-fashioned.

Training must be provided to ship’s crew on regular inspections of transfer equipment, their stowage on board, maintenance and replacement at appropriate intervals.

It was recommended during MSC 110 that the safest method is to secure the pilot ladder from an intermediate length on the ship’s deck is with a rolling hitch over the ladder side ropes by using 3-m ropes with resistance to 48 kN of breaking force.

It was also planned at this committee meeting that manufacturers produce new type-approved securing equipment with a breaking strength of at least 48 kN to prevent risks arising from fastening with a rolling hitch.

As of 1 January 2028, the method of securing pilot ladders from intermediate lengths by using shackles on deck will be phased out.

Finally, IMO has revised the Required Pilot Transfer Arrangements poster to include these amendments. Although the current posters will remain valid until 1 January 2028, the International Marine Pilots Association recommends posters on ships be replaced with new ones.

The 28th International Tug & Salvage Convention, Exhibition & Awards will be held in Gothenburg, Sweden, in association with Caterpillar, 19-21 May 2026. Use this link for more details of this industry event and the associated social and networking opportunities.

Related to this Story

Events

Offshore Support Journal Conference, Middle East 2025

Maritime Regulations Webinar Week

Maritime Decarbonization Conference, Americas 2026

Offshore Wind Journal Conference 2026

© 2024 Riviera Maritime Media Ltd.