Business Sectors

Events

Contents

Clean air - creating more efficient HVAC systems

HVAC systems offer a novel route towards achieving energy efficiency gains and improving shipping’s environmental credentials

The air conditioning system is one of the most demanding items on a vessel when it comes to electrical load-balancing. With a significant energy cost, operators demand that HVAC systems run as efficiently as possible, while providing a comfortable environment for passengers.

Teknotherm’s project manager Sigbjørn Tyssen notes the potential role digital technologies such as data analytics could play in making HVAC systems more efficient.

“The traditional HVAC skills such as fan curves, noise calculations and knowledge about refrigeration cycles will not go out of style,” Mr Tyssen says, but he adds that automation is becoming ever-more important.

“Knowledge of systems, such as AI, machine learning and neural networks is something we need to learn more about. The technology is there and the data must be collected.”

Mr Tyssen posits that rather than simply responding to input data such as outside temperature, or data from location systems such as keycards and ID cards being scanned, HVAC operations could take a predictive approach. This would enable the system to find patterns in demand and plan operations accordingly. For example, it could predict when guests are likely to be in different areas of the ship, such as the pool, cabins, restaurants and shops, and see whether these patterns are different depending on the weather conditions, and if the vessel is at sea or in port.

“The future HVAC system will react faster, but also move energy to where it is needed, plan when it is needed and produce it in the most energy-efficient way,” he says.

Recent and upcoming deliveries illustrate the role HVAC systems can play in boosting energy efficiency on passenger ships.

“Rather than simply responding to input data such as outside temperature, HVAC operations could take a predictive approach”

Celebrity Cruises’ 101.5-m vessel Celebrity Flora is due for delivery this year and has been designed for the Galapagos Islands. The sensitive nature of this environment has influenced many aspects of the vessel, resulting in a 15% reduction in fuel consumption and equivalently fewer airborne emissions in comparison with Celebrity’s Xpedition class.

A low-energy HVAC system is integral to reducing energy consumption and formed one of the main targets for efficiency improvements on the vessel. Heinen & Hopman are supplying custom-built chillers and Enigma fan coil units to assist in this. The Enigma operates on the principle of a minimum amount of fresh air calculated on a per-person basis being treated in an air handling unit and distributed through a thermally insulated spiro duct system and into a CFCU unit placed in the cabin’s wet module. When in the CFCU, this fresh air is mixed with returned air from the cabin and supplied through ceiling boxes with diffusers. The system reduces the size of chillers and ducting needed on board and the number of air-handling units required.

Stena RoRo has chosen Heinen & Hopman to supply a complete HVAC system for a newbuild ropax vessel. The vessel is being build by AVIC International, a Chinese yard specialising in ropax and roro vessels. The 214-m ship is the fifth in Stena’s E-Flexer ropax class. Upon delivery, the vessel will commence a 10-year bareboat charter with DFDS, plying a route in the English Channel between Dover and Calais. Environmental concerns were high on the agenda in the vessel’s design, and it is anticipated it will offer a 25% lower fuel consumption compared with current operations.

“The future HVAC system will react faster, but also move energy to where it is needed, plan when it is needed and produce it in the most energy-efficient way”

Heinen & Hopman will supply HVAC for living quarters and ventilation for the cargo hold, engineroom, machinery space, and provision cooling. The main challenges faced in the design are limited space and noise and vibration requirements.

A heat recovery wheel is being incorporated into the ventilation systems to aid energy saving. Comprising a circular honeycomb matrix made of heat-absorbing material, the heat recovery wheel rotates within the supply and exhaust air streams of air-handling systems.

As it rotates, heat is gathered from the exhaust air stream in half of the rotation and given to the fresh air stream on the other half of the rotation, transferring waste heat energy from the exhaust air stream to the fresh air stream via the matrix material.

Innovations seen in recent years that could make for more efficient HVAC systems include Halton’s CaBeam system. Unlike traditional systems that use fan coils, the CaBeam uses chilled beam technology.

This uses less components than a traditional system, as it has no filters to change or fans that consume electricity and require maintenance. It also offers lower sound levels and can ensure a uniform air quality inside cabins. Passengers can control the temperature via a touch panel from within cabins.

Do you need to change your refrigerant?

The progressive reduction of the EU’s hydofluorocarbon (HFC) quota has seen prices for high-global warming potential (GWP) refrigerants rise sharply.

With a further reduction of the quota set for 2021, Teknotherm has examined options for low-GWP and natural refrigerants for HVAC and refrigeration systems. When HFC and hydrochlorofluorocarbon (HCFC) refrigerants are no longer able to be replaced or become too expensive to replace, owners may need to look at the alternatives.

| Refrigerants and possible substitutes | |||

| Refrigerant | Type | GWP | Substitutes |

| R22 | HCFC | 1760 | R422D (GWP 2470), R417A (GWP 2130), R407C (GWP1260) |

| R404A | HFC | 3940 | R407F (GWP 1670), R449A (GWP1280) |

| R410A | HFC | 1920 | No suitable replacement (RW32 - GWP 667 - is flammable) |

| R407C | HFC | 1620 | No suitable replacement (R444B - GWP 295 - is flammable) |

| R134A | HFC | 1300 | R513A (GWP 573), [RW1234yf - GWP <1 - and R1234ze - GWP <1 - are flammable] |

Some potential alternative refrigerants, such as R1234yf and R1234ze, have additional safety requirements due to their flammability, while natural refrigerants such as carbon dioxide, propane and ammonia also require additional safety measures.

Chiller optimisation cools onboard power demand

Italian shipping company Grandi Navi Veloci (GNV) has cut power demand by 18% on 2,920-passenger ferry La Suprema by installing a digital system to optimise its use of chillers.

The technology uses onboard monitoring and data processing ashore, with a local onboard controller to adjust the chillers as needed. Optimisation is achieved through algorithms derived from real-time data sources including weather forecasts and machine learning and monitoring of 250 variables associated with the vessel’s heating, ventilation and air conditioning system.

Based on a target of saving 10% of the energy used by chillers, pilot results – verified by independent analyst Into Trend – cut power consumption by 18%. Applied continuously this would save the owner 70 MWh of power each month, with annual savings of up to €77,000 (US$86,400).

The optimisation project is unusual in focusing on energy consumption by HVAC systems and more generally on the hotel load, contrasting with the propulsion focus of many energy saving projects.

GNV marine operations director Antonio Campagnuolo said the project was an example of the owner investing in “modern and advanced solutions to renew onboard systems and improve energy performance and consumption.”

ABB has noted that chillers are the most demanding area of HVAC systems, making up 50% of total energy consumption on average.

Successful ammonia STS trial in South Africa

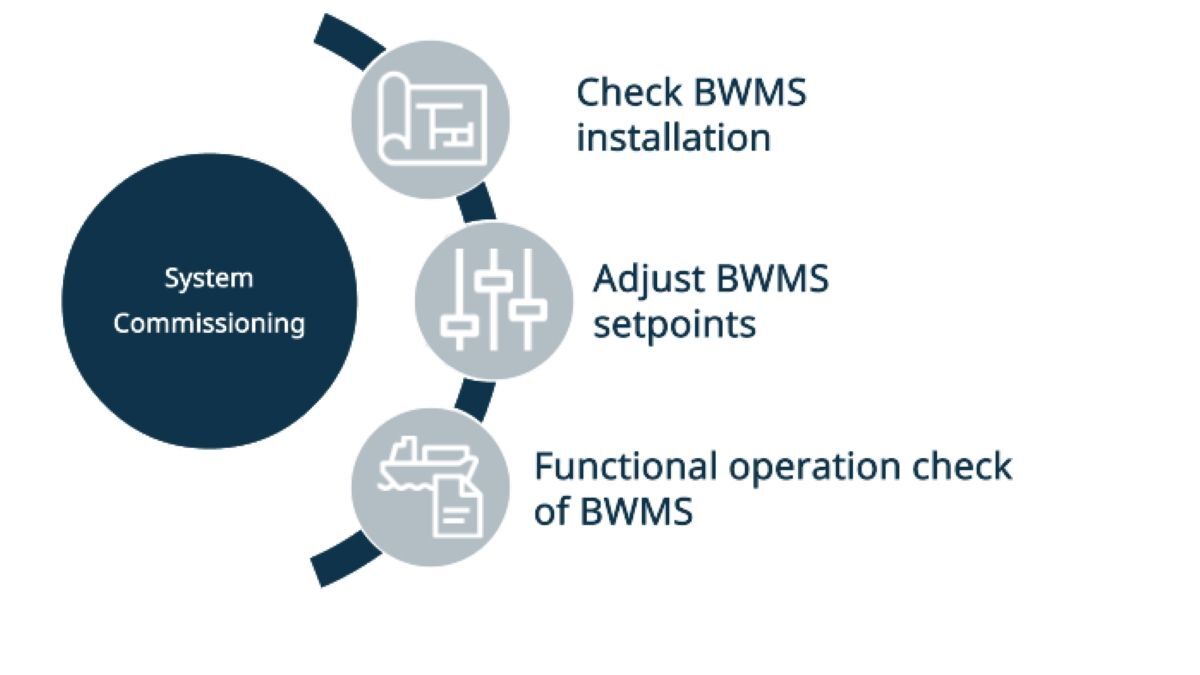

Why BWMS commissioning testing can fail

Related to this Story

Events

Maritime Cyber Security Webinar Week

International Chemical & Product Tanker Conference 2024

Marine Propulsion: Fuels Webinar Week

How enhanced connectivity is propelling maritime into the AI era

© 2023 Riviera Maritime Media Ltd.