Business Sectors

Events

Contents

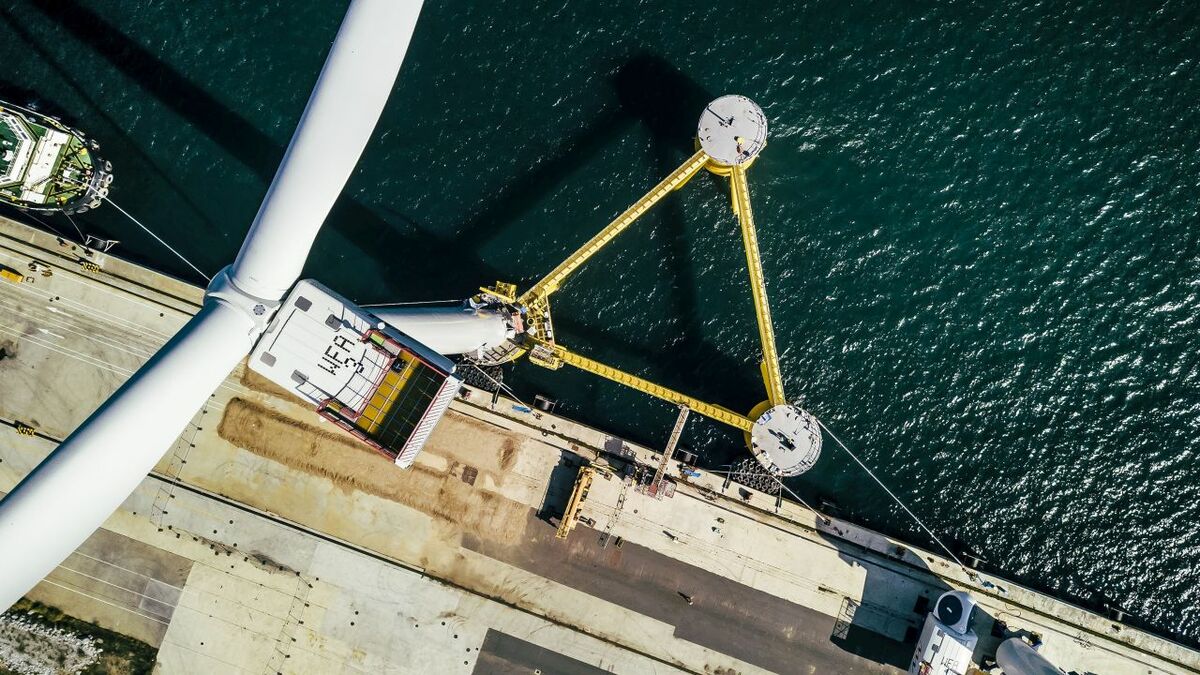

MHI Vestas: early engagement the key to floating wind

MHI Vestas Offshore Wind believes early engagement with customers for wind turbines and with foundation designers and manufacturers will be ‘essential’ in the floating offshore wind market, to an even greater extent than is necessary in the bottom-fixed market

MHI Vestas lead technical sales advisor offshore wind Albert Winnemuller told a DNV GL webinar on floating wind that early engagement with customers for turbines would be essential for a “fully integrated design loop” in relation with turbine generators, foundations and energy production.

The turbine OEM’s lead technical advisor said an integrated design loop is essential to address the trade-off between annual energy production, tower size, foundation size and cost.

He told the webinar there are numerous trade-offs involved, for instance between using a very stable but potentially more expensive platform and one that was lighter and sufficiently stable, taking into account parameters such as tilt angle and accelerations at the nacelle hub, loads on a turbine and how the many factors involved play into energy production.

“Wind turbine generator size and overall optimisation need to be carefully considered,” he said, noting that, in anticipation of commercial-scale floating wind projects it is engaged in a process of continuous improvement and optimisation of load simulation and controller models for floating turbines.

Mr Winnemuller told the webinar that assembly and installation processes used in demonstration projects to date had been low risk, but that its experience from those projects shows that both need further optimisation, and there is room for improvement in pre-assembly processes and using cranes onshore.

“There are a number of key questions that need to be addressed,” he said. “These include how the foundation supply chain will be set up, and whether the processes adopted will actually be able to keep up with the required pace to deliver cost reduction.”

Mr Winnemuller said operations and maintenance processes used so far had been ‘conventional’ and floating wind-specific optimisation of processes would also be required.

MHI Vestas already has an impressive track record in the burgeoning floating wind market, including a number of demonstrator projects, including WindFloat Atlantic, the Kincardine project offshore Scotland, and the upcoming Groix and Belle Ile and EFGL projects in France.

However, Mr Winnemuller said the company is now balancing its response to requests for more demonstration projects with the demands of getting engaged in larger, commercial-scale projects.

“It is time to move to large-scale projects,” said Mr Winnemuller, “and embark on the journey towards reducing the levelised cost of energy (LCOE) from floating wind,” as has already happened spectacularly in the bottom-fixed market.

Mr Winnemuller told the webinar MHI Vestas believes the floating wind market is “here to stay” and that although working with small-scale demonstrators had been extremely valuable, the next steps towards commercial projects now need to be taken.

If floating is going to have a commercial future, some form of subsidy will be needed to set it on the path toward cost reduction, he said.

It is time, Mr Winnemuller concluded, to apply the experience gained from demonstrator projects with 4-5 turbines to commercial-scale projects with multiple turbines, while ensuring there is a mechanism in place to help drive a reduction in LCOE.

Riviera will host a week of free to attend 45-minute webinars focused on offshore wind commencing 8 June. Register your interest now

Related to this Story

Events

Maritime Environmental Protection Webinar Week

The illusion of safety: what we're getting wrong about crews, tech, and fatigue

Responsible Ship Recycling Forum 2025

© 2024 Riviera Maritime Media Ltd.