Business Sectors

Contents

Cargo pumps: New arrivals and developments despite COVID-19

It was a busy 2020 for the cargo pump sector, which saw the return of a famous brand, logistical issues from COVID-19, introduction of VR for pump engineers and ATEX certification on products and quality management system.

There were many surprises in 2020, not least the Covid-19 pandemic, but for the tanker cargo pump sector a pleasant surprise came with the return of the Hamworthy brand, which has re-entered the tanker market and secured contracts to supply pump room systems for three large tankers, with an option for a fourth.

Two of the ships, both Aframax-size crude oil tankers, are being built by Hyundai Heavy Industries for the Finnish oil refiner Neste. The third, a 152,000-dwt DP2 shuttle tanker, is being built at COSCO Zhoushan Shipyard for Norwegian operator Knutsen NYK Offshore Tankers.

Hamworthy Pumps director, pump room systems Terje Bjornemo said: “We have a strong ambition to gain market share in pump room systems. Neste and Knutsen are crucial references for us in that context. We continuously develop our solutions in close co-operation with end-users, ship designers and strategically selected vendors. With these orders, we send the message that we have the expertise and the setup to deliver the customised pumping solutions the market demands.”

Hamworthy Pumps was previously part of Wärtsilä, but has resumed operations as an independent brand following a takeover by Scandinavian venture capital firm Solix. The re-entry into the tanker market is part of a larger growth plan, the company said.

Hamworthy Pumps worked with Danish electrical motor specialist Hoyer Motors, a subcontractor for electrical drive systems, to secure the orders for pump room systems for the three shuttle tankers.

Hoyer Group chief executive Henrik Sørensen said: “In recent years, we have strengthened our capability to serve the marine industry, including expanded facilities in China and a new range of ATEX and IECEx certified, explosion-proof marine motors. For these specific tankers we developed special water-cooled motors to meet the PRS requirements and will continue to invest in R&D as we strongly believe in the tanker market potential.”

Both companies are also in the process of significantly upgrading on service and aftersales. Hoyer Motors has taken active steps into the aftermarket and is represented via selected partners in Houston, Rotterdam, Singapore and Shanghai, among others.

Hamworthy Pumps is currently rolling out a new global service provider concept and has opened a large service centre in Singapore, together with its sister company Svanehøj.

Svanehøj director of sales and project, Johnny Houmann explained to Tanker Shipping & Trade the impact Covid-19 has had on the marine cargo market and how Svanehøj has coped. He said that when Covid-19 first appeared in early 2020, the core objective was to keep production running. Procedures were introduced to control the flow and movement of guests around the facilities. This included the offices, which were separated from the production floor with no mixing of personnel from either side. This was done with distance indicators and one-way systems.

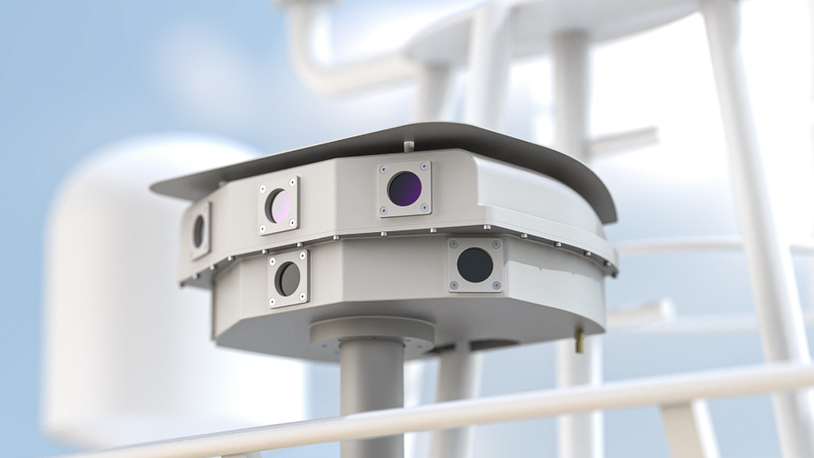

He explained that production was not interrupted, but it was a challenge to maintain sourcing with small suppliers. The company has had a positive dialogue with its sub-suppliers and this was thanks to the clear strategy in place, said Mr Houmann. He said a key feature has been Svanehøj’s ability to conduct remote Factory Acceptance Testing (FAT). Svanehøj’s FAT facility includes high resolution cameras and the ability to beam high volumes of real-time live data to clients during the FAT process.

Will this remain post-Covid-19? Mr Houmann believes so, noting: “The ease of sitting in front of a computer” will overcome the hours of travelling to achieve the same end.

At the other end of spectrum, technology is being used to educate future users and nascent designers of cargo pumps. Framo has invested heavily in the use of virtual reality (VR) technology for sales and trade fairs and is now taking the technology further.

“A large number of changes were introduced with the international carriage of dangerous goods regulation”

“Recent events have underlined the need for platforms that enable teaching and training to take place wherever you are, without meeting face to face,” said Framo’s training manager Gaute Flatøy. Together with NagellD, the maritime apprentice training office, Maritime Bergen and Bergen Maritime upper-secondary school, the group is developing educational content and simultaneously moving over to newer VR solutions with wider uses. The new technology involves computers and sensors integrated into VR glasses, eliminating the need for an external PC and cables.

“This VR technology makes it easier to carry out practical exercises with a group,” said Mr Flatøy. “Multiple participants can operate in the same world, even though they’re in different places.” The tool, which combines e-learning and practical exercises wearing VR glasses, will be used to develop expertise among both Framo customers and employees.

It will also be shared with maritime upper-secondary schools in Western Norway, as an instructive visual teaching programme. The technology enables students to ‘experience’ a chemicals tanker and see how it is constructed and works – something that technical instructor Reidar Gjesdal at Bergen Maritime upper-secondary school is excited about. He is an expert in hydraulic pumps and has spent several decades teaching both Framo employees and students.

“From a teaching perspective, using VR technology is a massive benefit – particularly when it comes to a subject like hydraulics, which is so abstract. It can show what is happening and make the subject more interesting. Usually, when you look at a pipe, all you see is the pipe, and it’s inert. It’s difficult to envisage an oil flow, but this is where the VR technology can help,” Mr Gjesdal explained.

He added: “Being able to take the pumps apart and put them together again, visualise the balance between hydraulic motors and centrifugal pumps, and get an idea of what’s happening inside the pipes is priceless. Simply grasping output and efficiency and gaining a greater understanding of general physics is a big benefit. I think we’ll get more people interested in the subject by visualising it with VR.”

ATEX certification on products and quality management system.

For owners and operators of inland waterway tankers and barges on the European waterway system, the last few years have been challenging. The industry has been plagued by low water levels in the river Rhine since 2018 and in 2019, the inland waterway system was brought into line with regulations on the international carriage of dangerous goods. The aim of the regulation is to promote safety and protect the environment.

A large number of changes were introduced with the international carriage of dangerous goods regulation, one being to harmonise with the ATmosphéres EXplosibles (ATEX) directive for explosive atmospheres. IMO has designated cargo tanks on inland waterway vessels as ATEX zone 0 – the highest risk of explosion. This requires that the cargo pumps must be constructed to operate normally in ATEX zone 0, and within parameters of malfunction without creating an ignition. This requires carefully chosen materials for the pumps.

With the collaboration of independent ATEX specialist 123ATEX, Dutch cargo pump manufacturer MarFlex has carried out an analysis of its deepwell pumps and subjected them to various ATEX tests. After extensive design reviews and a complete risk assessment the pumps had to be tested by a notified body.

MarFlex technics and QHSE manager Peter Raaijmakers said: “I was impressed about the large amount of severe testing and design verifications that had to be done to prove that our products comply with Annex II of the Directive 2014/34/EU. After passing all tests we all were very pleased.”

In a risk analysis, the construction was assessed for the correct use of materials and the correct tolerances. In addition, any potential ignition sources were identified to ensure the appropriate control measures were in place. For example, the oil contained in a bearing pipe is critical to provide lubrication for the bearings, which in turn prevents them from becoming too hot. But if the temperature on the outside of the bearing pipe becomes too high due to a lack of oil, then that can result in ignition. Checking the oil level, by means of a certified switch, is therefore an ATEX requirement.

To investigate the strength of a construction, the pumps were pressure tested and impact tested. The impact test consisted of a calibrated hardened steel weight, with a ball at the bottom, released from a height onto the part being tested. In addition, the pump was tested for the highest measured temperature, as well as stabilisation of the temperature under unusual conditions, such as an empty tank or a constant minimum tank level. In this test, the pump is operated until the temperature does not rise by more than 2°C per hour. The maximum temperature reached is then regarded as the ‘hottest spot’.

The MarFlex ATEX pumps conform with the requirement through a number of special features. These include the top cover of the deepwell pump being equipped with an oil-level sensor so that the pump stops automatically when the oil level in the top cover is too low. This prevents the bearings in the pump head and in the pipe stack from rotating and overheating without lubrication.

The ATEX certification takes into account that T4 level chemicals ignite at temperatures above 135°C. For safety reasons, the standard states that the temperature must not exceed 80% of this value, i.e. a temperature of 108°C. The dry run after discharging is set at a maximum of eight minutes. Tests have shown that safe discharging is still possible after 16 minutes, provided that the outside air or cargo temperature does not exceed 45°C. However, to eliminate the human factor during a dry run, extra protection must be built in.

ATEX requires reduction or elimination or static electricity to minimise the chance of ignition. In the MarFlex deepwell pump, the piston rod of the draining pump is completely insulated (by non-conductive seals), but there is a possibility that static electricity can be stored up, which can lead to sparking. To prevent the build-up of this static electricity, the piston rod must be constantly connected to earth. In the ATEX version, a carbon brush is installed for this purpose, which can be easily checked and/or replaced.

Finally, MarFlex complies with Annex IV of the Directive, which means the entire organisation had to fulfil stringent requirements that not only assure all supplied products are built exactly like the tested product, but also that training and procedures are in place to monitor for possible risks and improvements. Mr Raaijmakers said: “Being able to comply with this proves our level and focus on quality. Worldwide, only 200 companies achieved such status. We are very proud to be one of them”.

Related to this Story

Events

Maritime & Offshore Community Golf Day 2025

Offshore Wind Webinar Week

Maritime Decarbonisation, Europe: Conference, Awards & Exhibition 2025

Offshore Support Journal Conference, Americas 2025

© 2024 Riviera Maritime Media Ltd.