Business Sectors

Events

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

Contents

Register to read more articles.

Lifecycle analysis illuminates the future of onboard CCS

Project COLOSSUS reveals where onboard carbon capture sits within maritime decarbonisation strategies and emerging regulatory frameworks

The prospect of using onboard carbon capture and storage (OCCS) as a decarbonisation tool in commercial shipping has attracted both attention and investment. Yet questions remain about its actual emissions reduction potential when examined beyond the vessel. Project COLOSSUS delivers a comprehensive lifecycle assessment (LCA) study of OCCS technologies and their associated carbon value chains.

The study evaluates not only emissions produced and captured onboard, but also those associated with fuel production and the eventual storage or utilisation of captured CO2. GCMD described the objective as an attempt to “provide a coherent emissions accounting framework across upstream and downstream stages of the carbon lifecycle.”

To assess the emissions reduction potential of carbon captured onboard a vessel, Project COLOSSUS built upon an earlier study called Project REMARCCABLE, a collaboration between GCMD, the Oil and Gas Climate Initiative (OGCI), and Stena Bulk.

In that study, a conceptual and front-end engineering design study and cost estimate were conducted to retrofit a monoethanolamine (MEA)-based OCCS system onboard the Stena Impero, an MR tanker. The vessel, operating on heavy fuel oil (HFO), regenerates the solvent and liquefies the onboard captured CO2. It served as the reference vessel for Project COLOSSUS.

A practical limit of 40% gross capture was imposed due to volume constraints of the CO2 storage tank: “A 90% capture rate may be technically achievable, but storing such volumes of liquid CO2 onboard a tanker is unfeasible,” the study notes. Under these conditions, and considering energy penalties from operating the OCCS system, the net well-to-wake (WtW) emissions reduction is calculated at 28.5%. The estimated cost of avoided CO2 under this configuration, including transporting the captured CO2 within a range of 1,000 km to permanent storage, ranges from US$269 to US$405 per tonne.

While this figure is modest in isolation, the project demonstrates that broader emissions savings can be achieved by combining OCCS with low-carbon or carbon-neutral fuels. When the vessel is powered by biodiesel derived from used cooking oil (UCO), the emissions reduction reaches as high as 121% relative to the base case above. Bio-LNG and biomethanol similarly provide WtW savings of up to 98% and 119% respectively. These results are contingent on the biofuel feedstock and production method.

Liquefied natural gas (LNG) also improves the efficacy of OCCS integration. Its low sulphur content removes the need for upstream exhaust gas treatment, and the cold energy available from LNG regasification can be repurposed for CO2 liquefaction. With a 40% OCCS capture rate, an LNG-fuelled vessel achieves a 43.7% emissions reduction compared to the HFO baseline of 93.3 gCO2eq/MJ defined by IMO in 2008.

The study extends beyond shipboard performance to assess emissions associated with post-capture pathways. Three scenarios were modelled: permanent geological storage (CCS); CO2-cured concrete production (CCU); and the synthesis of e-methanol using captured CO2 and renewable hydrogen.

For permanent storage, two logistical chains were considered. In scenario 1a, CO2 was transported 200 km via pipeline to the ARAMIS reservoir near Rotterdam. Scenario 1b involved a 1,000 km voyage by CO2 carrier to the Northern Lights facility in Øygarden, Norway. Both pathways resulted in minimal additional emissions — less than 1% of the baseline — with total carbon value chain savings of around 27%.

In scenario 2, incorporating captured CO2 into concrete led to a 60% reduction in net emissions across the value chain. The study observes that this pathway offers benefits beyond shipping, since it displaces emissions from cement production. However, “careful attribution of carbon credits is essential,” GCMD cautioned. If shipowners retain the credit, concrete producers are not incentivised to participate in CO2-curing processes. Conversely, if credits are assigned to the concrete producer, the ship’s net emissions savings remain at 28.5%.

The final pathway examined the production of e-methanol. Here, the emissions impact depended almost entirely on how carbon credits were distributed. If a second ship uses the e-methanol and claims all credits, the original capturing vessel sees its emissions increase by 6.6% compared to the HFO baseline, due to the additional energy needs associated with onboard CO2 capture and storage. However, the e-methanol-consuming ship benefits from a 91% reduction, assuming the fuel is produced with renewable electricity. When credits are shared equally, both ships realise WtW savings: 11% for the capturing vessel and 54% for the one using the e-fuel.

The study makes a clear distinction between gross emissions capture and net value chain emissions. "An OCCS solution cannot be evaluated based on its onboard performance alone," the report states. Instead, it must be judged against the full carbon lifecycle: fuel origin, energy penalty, and the fate of captured CO2.

From a regulatory standpoint, Project COLOSSUS may influence how OCCS is treated within IMO’s evolving decarbonisation architecture. The study proposes that onboard capture be assessed using an “equivalent GHG Fuel Intensity” (GFI) derived from WtW emissions, enabling comparison with other fuels and technologies.

“An OCCS solution cannot be evaluated based on its onboard performance alone”

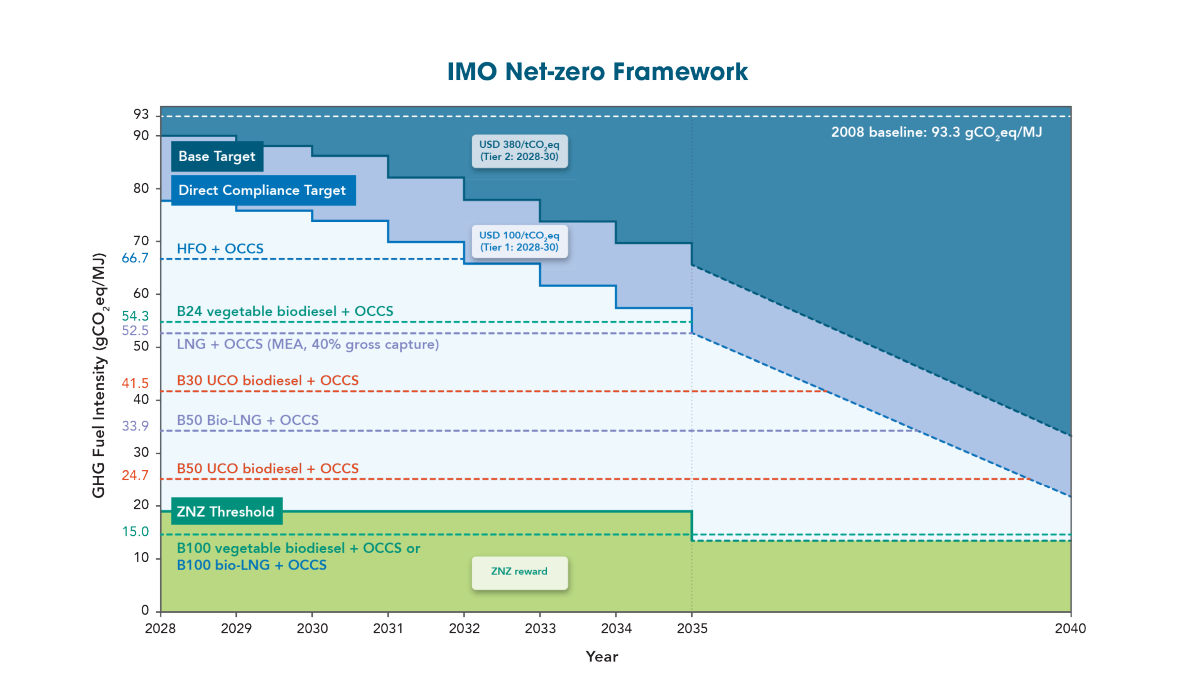

The results suggest that ships operating on HFO with MEA-based OCCS at a 40% gross capture rate would remain within IMO’s direct compliance GFI threshold until 2032. For LNG-fuelled ships using the same OCCS configuration, this extends to 2035. If biofuels replace fossil fuels entirely, OCCS-equipped ships could comply with the more stringent 2040 targets.

This compliance projection is not merely academic. IMO’s framework, including zero or near-zero (ZNZ) thresholds, could affect financial rewards and trading conditions under regional schemes like the EU Emissions Trading System. The potential of OCCS to reduce allowance surrender obligations will depend on whether CO2 storage or utilisation meets legislative requirements.

One area of concern is cost. The study, drawing on Project REMARCCABLE data, places the capture and avoidance cost of carbon for MEA-based OCCS with full-scale heat recovery at up to US$405 per tonne. This figure excludes any economic penalties from lost cargo space due to onboard storage requirements. While CCU scenarios — such as concrete production — can offer higher emissions reductions, their overall cost-effectiveness depends on the value chain’s ability to deliver low-carbon processing capacity at scale.

The analysis concludes by reinforcing the complexity of accounting. Without a consistent framework for allocating credits, assessing the performance of OCCS becomes ambiguous. The carbon molecule captured at sea may not produce a climate benefit unless its fate onshore is secure and the accounting logic robust.

In that respect, the first report on captured CO2 ship-to-ship transfer took place in Shanghai in June 2025, completed by Shanghai Qiyao Environmental Technology Co Ltd (SMDERI-QET), a subsidiary of the Shanghai Marine Diesel Engine Research Institute, which is part of the China State Shipbuilding Corp

The transfer involved CO2 that had been captured on board a container ship using SMDERI-QET’s proprietary OCCS. GCMD participated in the project and led the downstream pilot, demonstrating the carbon value chain after capture, with the CO2 transported by a tank truck to a CaCO3 production facility in Inner Mongolia. This effort represents the world’s first maritime pilot demonstrating how the full value chain of onboard CO2 could be implemented.

Riviera’s CO2 Shipping, Terminals & CCS Conference, Europe will be held in Milan on 8 September 2025. Use this link to register your interest and attend the event.

Related to this Story

Events

Maritime Regulations Webinar Week

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

© 2024 Riviera Maritime Media Ltd.