Business Sectors

Events

Contents

Uncoated ejectors can speed tank cleaning

Norwegian company, TeamTec, offers a wide range of ejector types, and sales engineer, Tor Olav Hagestad, believes that the material construction of TeamTec ejectors offers superior performance in the difficult conditions to which the internal parts are exposed. From the suction inlet, liquid is accelerated from approximately 2m/sec to 15m/sec and it can often contain foreign particles such as sand, rust scales and silt. All of TeamTec’s standard stripping ejectors that have a capacity of >100 m3/h are made in Ni-Al-Bz with a Monel nozzle, while smaller ejectors are made in bronze with an AISI 316 nozzle.

“Bronze metal ejectors are, for most mediums, superior against cavitation and corrosion and against general wear and tear. Furthermore, we can deliver ejectors made entirely in stainless steel or in super duplex materials for special installations on chemical or other tankers,” says Mr Hagestad. According to TeamTec, several manufacturers offer their products in cast iron or cast steel with internal epoxy coating on the inside.

This coating makes the casting parts pressure tight and prevents the steel from direct exposure to the stripped liquid; however, in a matter of months, this coating can be damaged, he claims. “TeamTec does not deliver ejectors made of cast iron. After years of experience and feedback from users, cast iron ejectors have been shown to have a low lifepan due to their lack of protection against cavitation and corrosion,” says Mr Hagestad.

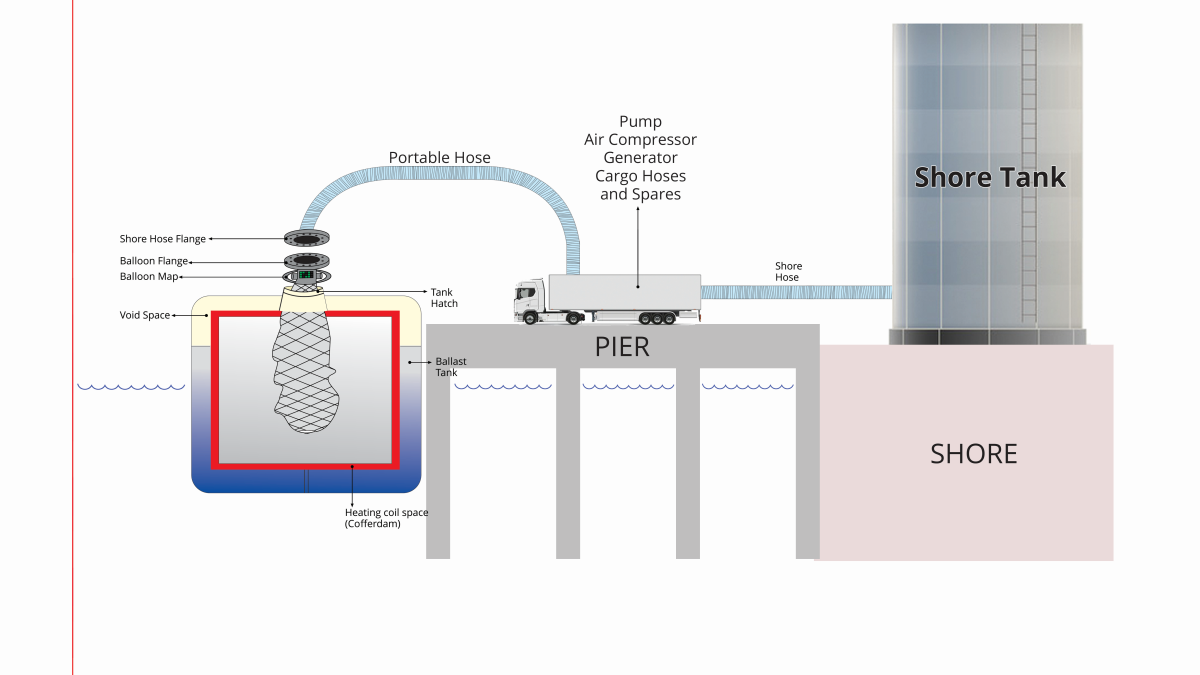

TeamTec ejectors can be used for stripping cargo and ballast tanks as well as cargo hold bilges. Portable ejectors are indispensible on product and chemical tankers where it is essential to empty the tanks completely, says the company, but they have many other uses on other types of ships for mopping up liquid from holds, cofferdams, sewage tanks and for the emergency stripping of pump rooms.

The ejectors are driven by water or oil supplied from conventional pumps. Efficient in-line suction ensures maximum suction capacity with the use of minimal driving liquid, says Mr Hagestad. “The results could mean smaller piping dimensions and smaller driving pumps.” TeamTec can custom make ejectors as its casting and production is all done in-house. TST

Related to this Story

Women in Maritime Today: Elin Saltkjel says no day working in maritime is dull

Events

Maritime Environmental Protection Webinar Week

Cyber & Vessel Security Webinar Week

The illusion of safety: what we're getting wrong about crews, tech, and fatigue

Responsible Ship Recycling Forum 2025

© 2024 Riviera Maritime Media Ltd.