Business Sectors

Events

Offshore Wind Webinar Week

Contents

Kotug plans international growth and innovations

Kotug International chief executive Ard-Jan Kooren explains the rationale for selling joint venture Kotug Smit Towage to focus on international operations and investing in future innovations

The northwest European harbour towage activities of Kotug International have a long history and in recent years, the European portfolio underwent structural changes. By partnering with Boskalis’ subsidiary Smit in 2016, Kotug strengthened its presence in 11 ports in four European countries. The integration of businesses led to further growth, synergies and smarter towage operations.

However, in Q1 2019, both Kotug and Smit announced the intention to sell Kotug Smit Towage to Boluda Group and to concentrate on growth outside north European harbour operations.

Kotug International chief executive Ard-Jan Kooren explains to Tug Technology & Business the reasons for this sale and the future of Kotug’s operations.

“As shareholders we unanimously believed that further consolidation of harbour towage businesses in Europe was needed sooner rather than later,” says Mr Kooren. “It was a logical step to ensure the continuity of the business.”

Part of the reason was the recent consolidation of shipping lines and how this led to these alliances seeking a single towage service provider in all European ports.

“When we set up the joint venture we looked for opportunities to enlarge the portfolio with more European ports, to meet this demand,” says Mr Kooren. “Discussions with Boluda were initiated, but Boluda presented itself as a buyer. We then decided to form a rock-solid combination of companies with a complementary network that could thrive in the years to come.”

This deal only relates to harbour towage activities in north European ports, leaving Kotug to concentrate on growing international business and developing towage technology.

Kotug retains its head office in Rotterdam and will continue to focus on offshore, harbour and terminal towage operations, chartering and its Maritime Excellence Centre, run by Tug Training & Consultancy. “Kotug in Europe will focus on the spot market in the North Seas in oil, gas decommissioning and renewables,” says Mr Kooren.

“There is a strong belief within the company that our innovative concepts will bring economical, technical and environmental benefits to our operations”

Outside Europe, it has a large presence in towage, offshore and terminal operations, as Kotug operates tugs in Australia, Malaysia, Brunei, Cameroon, Mozambique, the Bahamas, Russia and Egypt. “There is a strong belief within the company that our innovative concepts will bring economical, technical and environmental benefits to our operations,” says Mr Kooren. This should ensure Kotug retains the service-minded and innovative attitude of its founders.

“My father, Ton Kooren, has been a role model for me when it comes to competing by doing things differently,” he explains. In the late 1980s, Kotug assisted vessels in the Netherlands with two Rotortugs instead of four conventional tugs. “This gave us a unique position in Rotterdam,” says Mr Kooren. “The innovative approach is still very much alive in our daily business approach.”

In Australia, Kotug operates a fleet of Rotortugs to support Shell’s offshore Prelude project, servicing LNG tankers loaded with LNG from the world’s first floating LNG production project.

Kotug won this project by developing and implementing a unique Rotoring method that enhanced safety during operations. “This project illustrates how our approach is valued by clients like Shell, but also by captains who travel to Rotterdam to attend training sessions organised by our Maritime Excellence Centre,” says Mr Kooren.

Also in Australia, Kotug charters out tugboats to mining group BHP to support bulk carrier loadings at Port Hedland. From Q3 2019, Kotug will collaborate with Westug to operate nine Rotortugs servicing Fortescue Metals Group. These tugs are being built by Damen Shipyards at the Song Cam yard in Vietnam, with deliveries commencing from May this year, according to BRL Shipping Consultants.

“We have three more Rotortugs operating for Shell Brunei and seven tugs in Malaysia,” says Mr Kooren. Kotug also operates two Rotortugs at the SUMED oil tanker terminal in the Red Sea, Egypt.

“We are also supporting Vale’s bulk terminal in Mozambique with Rotortugs and we have activities with two Rotortugs at an oil terminal in Limbe, Cameroon,” he says.

All of these operations are enhanced by Kotug’s innovation drives, which has delivered manoeuvrability of Rotortugs, hybrid E-Kotugs and zero-emissions heat recycling systems. More recently, Kotug developed digital solutions for cutting fuel consumption and developing remote control technology.

“The innovative spirit is something we inherited. Innovation is in Kotug’s DNA”

“The innovative spirit is something we inherited. In fact, innovation is in Kotug’s DNA,” Mr Kooren explains. Kotug is harnessing OnBoard’s fuel management application on vessels in the fleet to reduce fuel consumption. This application enables tug operators to effectively analyse how the tugs perform in any given situation.

“This is a great example of how to achieve a reduction of operational costs and the potential environmental benefits through innovation,” says Mr Kooren. “By adopting emissions reductions early we hope to make way for a cleaner maritime industry in the near future.”

He says OnBoard’s application means Kotug could guarantee more than 16% of fuel savings worldwide from continuous monitoring and logging tug performance digitally.

Another Kotug project expected to help reduce the carbon emissions, is the collaboration with PortX. By using OptiPort software to optimise in-port vessel operations for towing, tug operators will achieve a significant reduction in mobilisation miles and subsequent fuel reductions.

“It all comes down to the smarter dispatching of tugs,” Mr Kooren explains. This applies big-data analytics, which seamlessly integrates available data sources, such as port management data, agency information and actual vessel positions. “This integration allows us to provide the most optimal schedule for any given situation in the port,” he explains.

Kotug invests in unmanned vessels and drones

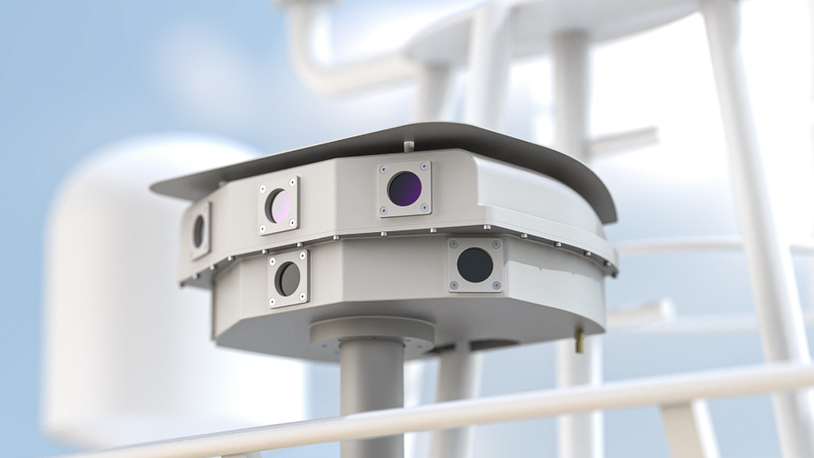

Kotug International’s management can see the benefits of using unmanned surface and aerial units for tug operations. In 2018, Kotug demonstrated the ability to control 16-m training Rotortug, RT Borkum, in the Netherlands, using a 360˚ bridge simulator in Marseille, France, as a remote-control hub.

“The purpose of this project is to gain knowledge in creating situational awareness on a remote bridge,” says Kotug manager for fleet performance and innovation Koos Smoor. “Development and testing are ongoing with our focus on being able to remotely control a fire-fighting tug.”

Kotug uses real-time sensor technology to monitor the position and surroundings, which provides the remote-control captain with the situational awareness needed for safely operating the training tug.

Kotug also recently patented a procedure for using a drone to connect a towline to an assisted vessel. Mr Smoor thinks this method could drastically improve the safety margin of tug operations. “The ultimate goal is to completely eliminate the need for tug operators to manoeuvre the tug close to the fore section of the assisted vessel, which is a potentially dangerous area,” Mr Smoor says.

Instead of crew members on the tug catching the heaving line of the assisted ship, a drone is used to deliver a messenger line from the tug to a predetermined location on the assisted vessel. This will allow the tug to safely sail beside the assisted ship and the crew to stay out of harm’s way.

Kotug operations

- Australia – offshore, chartering, bulk terminal operations

- Bahamas – port towage

- Brunei – oil terminal operations

- Cameroon – oil terminal operations

- Egypt – oil terminal operations

- Malaysia – port operations

- Mozambique – bulk terminal operations

- Netherlands – Maritime Excellence Center

- Russia – oil terminal operations

- North Sea – offshore, renewables, decommissioning

Kotug’s innovations

- Hybrid E-Kotug for reduced emissions in port

- OnBoard Fuel monitoring means 16% fuel savings

- PortX OptiPort optimises in-port vessel operations

- Remote control technology for fire-fighting tugs

- Drones for mooring line connectivity

- Onboard gas fume detection

Snapshot CV: Ard-Jan Kooren

Ard-Jan Kooren has worked in the family-run company since 1990 after studying at universities in Antwerp, Belgium, and Phoenix, USA. He worked his way up with time as manager for marketing and operations, vice president and commercial director, before becoming the president and chief executive in 2002.

Related to this Story

Events

Offshore Wind Webinar Week

Maritime Decarbonisation, Europe: Conference, Awards & Exhibition 2025

Offshore Support Journal Conference, Americas 2025

© 2024 Riviera Maritime Media Ltd.