ITS 2016 Boston

The need to improve standards of safety within the tug industry was the major recurring theme of the 24th ITS Convention.

The opening keynote address was delivered by American Waterways Operators’ president and CEO, Tom Allegretti, who also gave the inaugural address in Seattle in 1996. ITS last visited the United States in 2004 when the event was held in Miami.

In Boston, he said: "Our industry’s safety journey over the past quarter-century has been nothing short of remarkable. We are a better, safer industry with a dramatically reduced environmental footprint. Coast Guard casualty statistics testify to this fact, showing significant, measurable declines across the whole array of safety metrics: crew fatalities, personal injuries, oil spills and vessel casualties."

Along with various aspects of safety and upcoming environmental legislation, papers presented at the event focused on technical innovations, best practice, lessons learned and inspirational ideas and thoughts on what are likely to be momentous changes in the tug, salvage and offshore sectors in the not-too-distant future - all against a continuing backdrop of an extremely tough economic climate.

Among the high-profile speakers were: Rob Allan, executive chairman of Robert Allan Ltd; Tom Guldner, president of Marine Firefighting Inc; Govinder Singh Chopra of SeaTech Solutions; John Witte Jr of Donjon Marine, who is also president of the ISU; Andres Banck of Caterpillar Marine and Roland Schwandt and Stefan Buch of Schottel.

At ITS 2014 in Hamburg, the programme included a one-to-one Q&A session between conference chairman Mike Allen and Costa Concordia salvage master Nick Sloane. The format proved extremely popular and so, at ITS 2016, there was a similar high-profile exchange between Mike and Todd Busch, senior vice president and general manager, technical services, Crowley Maritime Corporation. Busch is also chairman of the board at newly-formed Ardent.

"At the convention, there was a diversified group of people from all parts of the world, in a wide variety of the tug and offshore/salvage environments. Getting to network with some of the delegates was an experience you could not achieve anywhere else but at this conference."

Craig Williams, Riverside Marine

"Without doubt, attending ITS is an important strategic undertaking that has always proven a wise choice."

Capt Arie Nygh, SeaWays Consultants

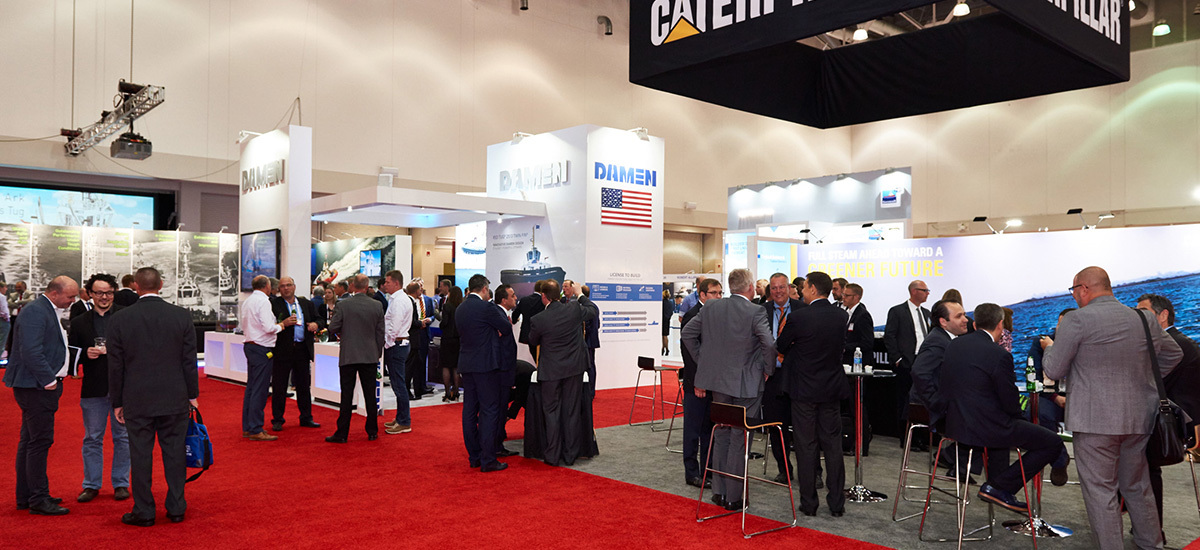

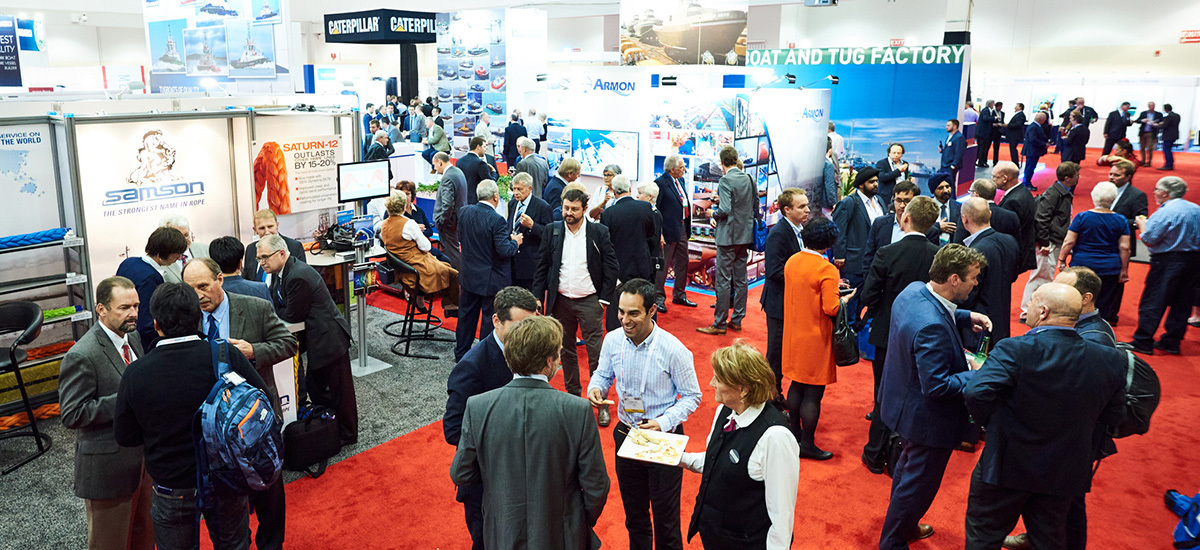

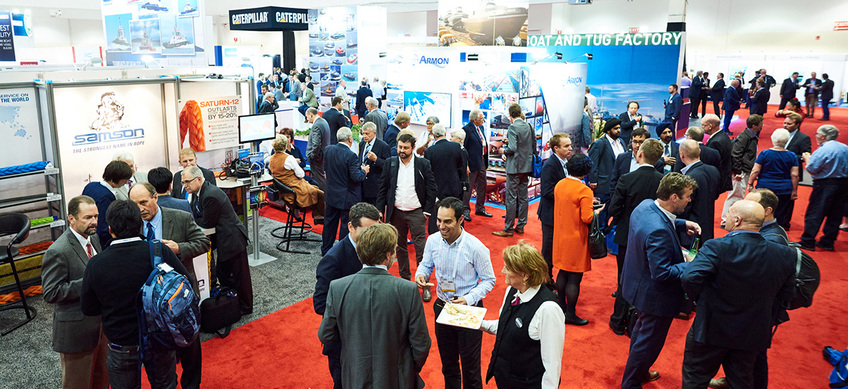

There were more than 100 stands from more than 40 countries in the exhibition area where companies displayed state-of-the-art technologies and designs and took the opportunity to showcase a diverse range of products to the top-level decision-makers and industry leaders attending the event.

As at previous ITS events, companies chose to use the exhibition hall to make significant announcements about business developments and contracts.

Maritime training company SeaWays and classification society ClassNK toasted their new partnership with champagne when they announced that ClassNK was in the process of assessing, with a view to certifying, SeaWays training programmes - the first such classification aimed at setting high-level standards of safety and technical skills which both organisations are hoping will be mirrored throughout the industry.

Capt Naoki Saito, manager of ClassNK’s certification service planning department, said: "With this co-operation in tug master training, we are looking to further contribute to the safety of tug and salvage operations."

Neil Sadler, contract director of SeaWays Europe, said: "We believe that bespoke training is necessary for different classes of vessel. With high-powered tugs you cannot be complacent about competence. That is why we have decided to work towards making things safer."

Caterpillar Marine and Svitzer Europe signed a contract at ITS that will see Caterpillar using state-of-the-art technology to monitor data from Svitzer’s entire European fleet to maximise operational efficiency and spot any need for mechanical adjustments before they become a more major and more costly problem.

Rob Bradenham, global sales and business manager, Caterpillar Marine Asset Intelligence, said: "Asset intelligence is harnessing technology and services for using data from different systems on board to help owners and operators get more out of assets, avoid downtime and decrease operating costs. We can identify issues before they become a big problem. We also help owners understand how their vessels are being operated to enable them to utilise their entire fleet in an optimum way. A modern diesel engine, for example, may have around 100 sensors on it.

"We collect data from the sensors attached to engines, generators and propulsion units - everything from gas turbines to simple pumps. We focus on tailoring implementation to individual vessel types.

"We’re working with Svitzer Europe to figure out how it can incorporate this knowledge into its business. It’s not all about technology, it is also about how vessels are operated by their crew. We have senior-level buy in and will work with both on board crews and on shore tech’ teams.

"In the past those on board may have thought that there was a problem developing, but would have to wait for on shore support. Now both can have instant access to information about how the vessel is performing."

"I thoroughly enjoyed the papers’ content and presentation and the social side was fantastic."

Kent Stewart, Maritime Contractors.

"It was a good opportunity to understand trends and concerns in the industry and to network with many key players."

Corey Parker, Caterpillar Marine.

The ABR Company is grateful to the generous sponsors who helped make ITS 2016 Boston such a special event. Samson sponsored the delegate bags and registration as visitors arrived.

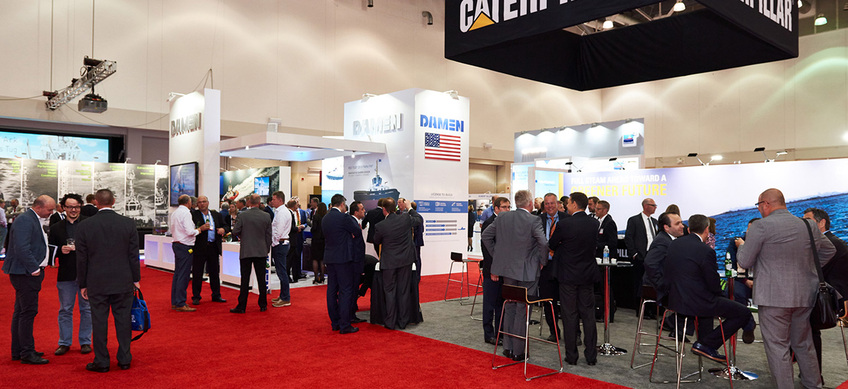

Damen hosted the popular invitation-only ITS Golf competition and the harbour-side Welcome Cocktail Party.

Uzmar sponsored the delegate and exhibitor lunches throughout the event, and Armon hosted Happy Hour in the exhibition hall at the close of the first day of the event.

Cashman Equipment hosted a quintessentially Boston evening at the House of Blues, which included the chance for delegates to enjoy a large slice of Americana at a Red Sox baseball game at the iconic Fenway Park stadium.

The conference’s formal business sessions ended on the afternoon of Thursday 26 May, but the social calendar continued that evening with the hugely popular Gala Dinner, a sumptuous four-course meal followed by dancing until midnight, sponsored by Caterpillar.

The Shipowners’ Club and Sanmar were joint sponsors of the next day’s boat tour taking in the historic sights of Boston Harbour, including a visit to Luna, the last surviving, full-sized, wooden ship-docking tug on the US Gulf and Atlantic coasts.

"It was a great choice of venue and had the usual attention to detail from ABR, good networking opportunities, good food and social arrangements."

Nigel Hartley, British Marine

"ITS remains the prime event to meet and mingle with people within the industry."

Richard Janssen, SMIT Salvage

After such a positive response to ITS 2016, there is already much eager anticipation about the ITS 2018 convention, and planning for that event is already underway.

"A good event … a real chance to generate future business."

Daan Merkelbach, manager tug training and consultancy, Kotug International

"An excellent high profile attendance."

Walid Elmallah, Al Masaood

"An excellent meeting place for the worldwide tug industry as always."

Steve Dougal, Century Marine

"This is the show to beat!"

Kim Cleggett, IMS

The world’s largest gathering of Tug, Towage and Salvage experts

The ITS Convention and Exhibition started life as the International Tug Conference in 1969. At the 10th Conference in Sydney 1988, salvage was introduced into the programme for the first time, and the conference was renamed the International Tug and Salvage Convention and Exhibition.

The event, held every two years in a different location, is the world’s largest gathering of tug, towage, and salvage experts. Over the past 50 years, the convention has earned an enviable reputation for being the best of its kind. It attracts the most senior executives in the business, affording them a unique opportunity to meet, learn and discuss projects or contracts.

The convention has grown significantly and now attracts more than 1000 attendees and 100 exhibitors.

Since 1969, over 8,000 delegates and 1,200 exhibitors from 50 countries have taken part in the conventions.

"I realised that my entire career and the international success of our business have been inextricably linked with these conferences. Through them we have met the majority of our international clients, have been given the platform from which to draw attention to the important unique design developments initiated by this office, and been able to share ideas about the future of tug design and operations with a worldwide audience"

Robert Allan, Robert Allan Ltd

Programme

Official Opening and Keynote Address

THOMAS A ALLEGRETTI, President & CEO, The American Waterways Operators, USA

The State of Tug Safety Today

ROBERT ALLAN, Executive Chairman, Robert Allan Ltd, Canada

The early months of 2015 witnessed more than a few accidents involving tugs, and unfortunately also a significant loss of life. Tug power/size ratios and the overall propulsion and winch configurations used today have far exceeded those envisaged when the current rules and regulations for tug stability and other safety considerations were developed, mostly in the early 1970s. This paper looks at some of the issues facing tug safety today and offers some suggestions for avenues of further research and development.

Designing Safer Tugs - Going Beyond Existing Statutory Stability Criteria

GOVINDER SINGH CHOPRA, Director, SeaTech Solutions International (S) Pte Ltd, Singapore

The recent number of tugs capsizing raises the question as to whether the International Maritime Organization’s (IMO) criteria for stability is adequate. Its applicability to tugs and offshore workboats such as PSVs, diving support vessels and anchor-handling tugs, however, appears to be limited. These operations are completely different from commercial vessels and these boats have to withstand much harsher operating environments. The stability criteria must cater to actual operations and consider the dynamics and motions of these boats in the seaway. This paper will analyse the limitations of present criteria, with case studies to demonstrate the need for modification, and will then go on to suggest a direction for further research to develop a stability criteria better suited to tugs and similar workboats.

Hybrid and Diesel-electric Propulsion Systems - Tailor-made Solutions for Every Workboat

ROLAND SCHWANDT, General Sales Manager, Schottel GmbH, Germany

STEFAN BUCH, Director Automation & Systems Technology, Schottel GmbH, Germany

In recent years the maritime industry has seen a significant change in philosophy regarding the environmental effect of carbon fuels. Clean technology is becoming an increasingly important issue. Diesel-electric and hybrid propulsion systems have moved into the focus, in particular for vessels with extreme load variations in their profile. A variety of these systems have been developed and are already in service. Based on the experience gained, this paper will discuss the differences of various hybrid and diesel-electric propulsion systems. The range of hybrid solutions includes inline or PTI motors and hybrid full diesel-mechanical systems.

Dual Fuel Differentiation - Engineering Power Solutions to Mimic Diesel Performance in Gas Mode

ANDREAS BANCK, Engineering Manager, New Technology Introduction - Performance & Simulation, Caterpillar Marine, Germany

For decades, diesel engines have served as the lone power solutions for tug, salvage and offshore applications. In the commercial marine industry, vessel operation with diesel engines has been based upon unlimited operation in low, stand-by load and fast load acceptance. In recent years, dual fuel engines have emerged in the marine market, offering vessel operators a viable alternative to enhance fuel flexibility. From an operational standpoint, typical dual fuel engines vary from diesel engines significantly in regards to a slower load acceptance. This paper examines the MaK dual fuel solution which differentiates itself in the market by running like a diesel engine while operating in gas mode. The paper will discuss key features engineered into solutions to ensure safe operation while maximising efficiency and minimising emissions.

It’s All About Bollard Pull

KENT STEWART, Managing Director, Maritime Contractors Pty Ltd, Australia

Have we ever heard a harbour master say he doesn’t want tugs with more bollard pull? Or an oil company knocks back an anchor-handler because of too much bollard pull? Unlikely. With bollard pulls approaching 300 tonnes, do we really appreciate the relevance of these figures? How much more do we need? Is 400 tonnes the limit? Is there a disconnect between theoretical calculations and practical seamanship? Are empirical bollard pull formulae causing confusion? Can too much bollard pull be dangerous? The author will examine the history of bollard pulls and the impact on our industry today - the myths and confusion and even the misguided emphasis placed on bollard pulls.

Safe Operation with Synthetic Fibre Ropes in Dynamic Applications

BERNABE GALLARDO, Application Engineer, Samson Rope Technologies, USA

JUSTIN SMOAK, Application Engineering Manager, Samson Rope Technologies, USA

As more dynamic applications adopt fibre rope technologies, understanding the mechanisms that define rope performance and its dependence on hardware interactions has become a critical element to the success of high performance fibre ropes. Dynamic mechanisms affecting rope behaviour and performance include mechanical wear, dynamic loading and the related need for energy absorption, rope recoil, and heat generation, amongst others. Understanding of these mechanisms not only provides insights into product design and field operations, but also important information for supporting the design of interacting hardware. Equipped with this new information and newly developed rope technologies, we will discuss how to mitigate these mechanisms and best practices to further improve load management and operational safety.

Tugconomy: A Value-Based Towage Approach

MARINUS JANSEN, Technical Innovations Manager, Rotortug BV, The Netherlands

’Tugconomy’ is a concept that describes a structured value-for-money framework for determining performance space requirements for greenfield marine operations. Tugconomy aims to exclude biases, both positive and negative, in order to provide operators and other stakeholders in greenfield developments with a transparent development cycle. Studying different tug concepts in competition during the development cycle, and including non-normal operations in the process, will provide all stakeholders with a consensus on the ALARP towage solution for their prospective projects.

Safety and LNG Bunkering

THOMAS GULDNER, President, Marine Firefighting Inc, USA

MARGARET KAIGH DOYLE, General Manager, Gas Technology Institute (GTI), USA

The use of liquefied natural gas (LNG) as a fuel is rapidly becoming more widespread. New environmental regulations, as well as fuel costs, are causing fleet owners and operators to consider building new vessels or re-fitting existing vessels to burn LNG as a fuel. Legislation, technology and training are struggling to keep up and procedures are constantly being written and re-written to meet the new challenges. What should you know about the LNG you are bunkering on your vessel, or the one tied up next to you?!

Does the Regulatory Environment in the US Improve Provision of Salvage Services Compared with Europe and Other Parts of the World?

JOHN A WITTE JR, Executive Vice President, Donjon Marine Company Inc, USA

Provision of salvage in the USA differs significantly from Europe and other parts of the world. More than 25 years on, Exxon Valdez still casts its shadow through the requirements of OPA90. It created strict requirements for contingency planning and response to pollution incidents. There is a rigorous liability regime and it requires vessel response plans with named salvage providers. Along with the Jones Act, it creates a complex operating environment. How is it different operating within this framework compared with other territories? What are the commercial and operational implications? Does it improve or detract from effective response?

Reformation of the Marine Salvage Industry

MARK HODDINOTT, General Manager, International Salvage Union, UK

The past decade or so has seen some dramatic changes in the marine salvage industry’s commercial and operating environments. The use of Lloyd’s Open Form has continued to decline with alternative contracts becoming more popular. Vessels have become much larger with the potential for making salvage more difficult and expensive. Salvage companies have continued to move from private to corporate ownership and we are seeing mergers and consolidation. Protection of the environment has become more important than ever and remains the priority above saving of property. This paper analyses the changes and what they mean for the future of the international marine salvage industry.

The Small Scale LNG Supply Puzzle

CAPT GARY DOCKERTY, Sales Director, AMEA Region, Sanmar Shipyards, United Arab Emirates

Much has been written and presented over recent years about alternative fuels in the maritime sector - particularly LNG. While several tugs and OSVs fuelled by LNG have entered service, wider adoption of LNG fuel remains elusive, despite its undisputed environmental benefits and conceivable economic benefits. This paper will present a detailed analysis of the global LNG market, the current status and projected growth in the small scale LNG supply chain, the macro trends driving the use of LNG as a marine fuel and the constraints to its wider adoption in the workboat and OSV sectors - together with recommendations as to the steps needed to see its wider use accelerated across the maritime community.

Revolutionary RAmora Brings Tele-operated Capability to Ship-handling Tugs

VINCE DEN HERTOG, Vice President, Engineering, Robert Allan Ltd, Canada

DR OSCAR LISAGOR, Vice President, Naval Architecture, Robert Allan Ltd, Canada

Drone technologies are set to open up a new realm of possibilities for tug operations. The uncrewed RAmora 2400 is the flagship within Robert Allan Ltd’s new TOWBoT (Tele-Operated Workboat or Tug) class. Equipped with an advanced control system derived from ROV/AUV technologies, this highly manoeuvrable vessel is designed to work in tandem with a conventional tug during ship handling, while being operated remotely by an experienced tug master. Also bringing capability for close proximity fire-fighting, spill response, and toxic environment operation, TOWBoT vessels such as RAmora have the potential to become powerful new players in the modern tug fleet.

Case Study: LNG Tug - Two Years in Operation

SAMI UOTINEN, Area Sales Manager, Rolls-Royce OY AB, Finland

Rolls-Royce is a global marine company with a strong emphasis on performance, safety, quality and the environment. The worldwide concern with emissions and subsequent regulations gives an incentive to the industry to develop new technologies to meet the increase in customer demands. Low emissions operation is a prime focus for owners building new vessels. The introduction of natural gas as a fuel for marine propulsion has become a game-changer in terms of emissions as the fuel itself contains considerably lower amounts of the regulated NOx, SOx and particulate matter (PM). Rolls-Royce has a long history in the business of engines operating on natural gas, which started in 1991 with the first land engine, and, for marine applications, the first engine was installed in 2006. The company developed the gas engine from scratch as a pure gas, lean burn, engine. It does not need any pilot fuel. This is the most efficient way to burn the gas, which in turn gives the lowest emissions and fuel costs. Based on this technology, it creates LNG-fuelled propulsion systems for all kinds of vessels worldwide. In 2013, Rolls-Royce delivered LNG-fuelled propulsion systems to the world’s first two LNG tugs for operation in Norway.

MTU Solutions for EPA Tier 4/IMO Tier III Including Diesel and Gas

MACIEJ KOWALIK, Marine Application Engineering, MTU America Inc, USA

TIM PETERS, Marine Application Engineering, MTU America Inc, USA

This paper describes the technology employed by MTU to satisfy the latest Environmental Protection Agency (EPA) and International Maritime Organization (IMO) emission requirements for the global marine market. MTU’s strategy for EPA Tier 4/IMO III is to provide operators with propulsion system options - diesel as well as natural gas engines. The main topics of this paper are: the technologies used to achieve EPA Tier 4/IMO III requirements for high speed marine diesel engines and lean burn marine gas engines (including associated installation requirements and costs) and the competitive advantage of each technology; the cost of ownership of both technologies; external factors that affect the technology selection process for a specific customer and application, and general diesel and gas field experience. On the diesel side, the implementation of in-cylinder technologies, coupled with a selective catalytic reduction (SCR) after-treatment system and the necessary control system to ensure both systems work in harmony, are necessary to satisfy the latest EPA/IMO emission requirements. On the gas side, IMO III is achievable through the implementation of in-cylinder technologies only, where EPA Tier 4 will require an oxidation catalyst.

Combined Pilot/Tug Master Training - The Experience and Advantages

PETER KROGSGAARD SØRENSEN, Vice President, Maritime Division, Force Technology Division for Maritime Industry, Denmark

Combined pilot/tug master training using advanced simulators and training methods has proved to be highly efficient, as it provides a professional insight and understanding of the challenges faced by both pilots and tug masters. Over the past decade, we have seen significant development in tug designs. The capability of these advanced and highly manoeuvrable tugs has to be understood by both the tug masters and the pilots in order to use the new tugs to their full potential. The urgent need for training is exemplified by observations during such training where younger pilots, due to their experience with very responsive systems, are giving orders to the tugs at a pace that cannot realistically be executed due to the inertia that still exists when handling modern tugs. More experienced older pilots are used to this inertia and consider this when ordering tug manoeuvres. The trend with large vessels fitted with smaller engines due to fuel/emission reduction requirements will increase the demand for tug assistance and hence the demand for training of both pilots and tug masters as the manoeuvrability is affected. Likewise, the increasing regulations restricting maintenance, repair and painting in port makes it more and more expensive to repair and maintain the tugs. This also underlines the importance of understanding tug handling principles to avoid damage to the tugs. It emphasises the importance of both technical ship handling and the human factors aspects, ie the importance of professional communication, in order to achieve the highest possible degree of situational awareness between pilot and tug, and executed in a way that makes it possible for the ship’s captain and crew to follow the intentions and operation. The overall aim of training is to keep tug operations safe, efficient and profitable. This paper will focus on a teaching-based approach which has proved to be highly efficient with regard to both technical aspects and human factors. Further, the paper will address some of the pitfalls and how such training can be combined with, and based on, efficient selection tools which can also be used to ensure that the right candidates are hired and any possible inappropriate behavioural strategy detected and addressed.

Tracking Stress and Workload in the Maritime/Tugboat World

DIMITRI VAN HEEL, Sr Project Manager, Teamleader Nautical Operations, MARIN (Maritime Research Institute Netherlands), The Netherlands

KERSTIN KLINKENBERG, Partner, K + S Projects, Germany

The Dutch research institute MARIN, the Technical University of Berlin, Philips and k+s projects would like to present the findings of a pilot study into stress/workload measurements during training in a ship-handling simulator. Working on a tug has unique demands, made more challenging by fatigue and a high workload, and influenced by special demands such as noise, the intense mixture of private and work life and what often prove to be extreme environmental challenges. The objective of this pilot study is to determine the most suitable tool to determine the workload a person experiences when executing complex tug manoeuvres. Scenarios are selected strictly according to real life on the bridge, focusing on tugboat reality. Measurements include heartbeat rate and skin conductivity, plus an EEG, but also include simulator signals. The human body is a very sophisticated control circuit, and to choose different ways of looking at the way a human expresses himself is like joining puzzle elements to a complete picture. Together they pinpoint what is most challenging for the test person. The findings will be evaluated to assess which signals are most suitable to obtain a reliable workload indicator. This tool can be used to study the impact of job procedures, modern bridge design and time/work shift systems, but also to measure the effectiveness of training programmes. The pilot study is the follow up of the demonstration of ’Training meets Science’ during ITS 2014 in Hamburg, initiated and organised by k+s projects, University of Applied Sciences Bremen and University of Technology Berlin.

Designing for Safety - Hybrid Tugboat Battery Safety Vessel Design and Construction Parameters for Lithium Batteries

ANDREW EYDT, Vice President of Engineering, PBES, Canada

An increasing number of workboats are currently being deployed in hybrid form. These hybrids range from newbuilds to retrofits of existing 20 or 30-year-old vessels. Payback on investment is a critical component in the decision to convert or build a hybrid workboat. However, the benefits of redundancy and increased safety are often overlooked. A vessel employing a large battery or energy storage system (ESS) not only operates more efficiently, it also has the ability to draw upon a reserve of energy instantly. This energy may be used as spinning reserve to keep the vessel from harm’s way in the event of power loss, provide emergency navigation and hotel loads, auxiliary propulsion power and even extra bollard pull to the main drives in the event of an emergency situation while towing. While these and other advantages, such as the environmental and cost savings benefits, are well documented, the real world experiences of my team will help vessel owners and designers understand how to design and integrate a lithium energy storage system for safe, reliable use, now and for years to come. Simply put, batteries will reduce a vessels exposure to risk and make it fundamentally safer to operate, while providing economic gain for vessel owners.

Reminiscences of a Practising Tug and Towage Lawyer

SIMON TATHAM, Partner, TugAdvise/Tatham Macinnes, UK

Admiralty law, which includes collision and salvage amongst other instances, is colloquially known as the law of ’bumps and scrapes’, but it is the scrapes of one English Admiralty solicitor, representing parties around the world over thirty five years, that is the focus of this paper. Those practising in shipping law in the City of London have the rare pleasure of attaining a high level of specialisation in their field, and the privilege of sharing that with their clients. This is thanks to the prevalence of English law in trade, and shipping in particular, as well as the enduring choice of London as a venue for the resolution of disputes. The breadth of practice is narrow, the law is highly developed and sometimes arcane and complex, but every case is different, and for those who fall into shipping law, there is often no return as the author found, sometimes to his near peril.

Damen RSD Tug 2513

ANDRÉ DE BIE, Senior Design and Proposal Engineer Tugs, Damen Shipyards, The Netherlands

ROBERT VAN KOPEREN, Development Team Leader R&D, Damen Shipyards, The Netherlands

As a result of increasing vessel sizes, tug operations in ports are becoming more demanding for both tugs and their crew. Larger vessels in confined rivers and basins, as well as the increasing speed of operations, have resulted in a change in the safety of port operations. Efficient and safe operations reduce risks, time and money for the operators. New insights and lessons learned from the successful Damen ASD and ATD Tug series led to a revolutionary new concept - the reversed stern drive (RSD) Tug 2513. Key words for the Damen RSD Tug® 2513 are compact, powerful, high performance, safe, predictable and responsive. The RSD Tug 2513 will be equipped with a revolutionary patented twin fin skeg design which will lead to predictable sailing performances, giving the operator optimal towing performance both at the stern and at the bow of the assisted vessel. By offering one type of tug for all modes of operation the safety will increase as crews need less familiarisation time and costs will reduce for the operator. In close co-operation with the company’s research department, extensive model tests for the verification of directional course stability in both sailing directions were conducted and CFD calculations were used to optimise the hydrodynamic performance. The RSD Tug 2513 is the only compact tug designed to work bow first. Operators never have to reposition their tug working in indirect or direct mode - at all speeds, sailing ahead and astern as a stern or bow tug respectively. A broad view of the safety aspects was taken into account during the design of the RSD Tug 2513. This included the human machine interface (HMI) factor, hull and equipment layout, low noise levels and quick engine response, among other things. Damen expects this integrated approach to revolutionise the tug world. This in turn, will lead to safer operations. After the successful introduction of the Damen Hybrid Tugs (today there are seven in operation), the RSD Tug 2513 with natural gas (NG) driven engines is the next innovative environmental development. The RSD Tug 2513 CNG will be a pure NG-powered vessel, with high-speed engines in combination with compressed natural gas (CNG) storage. In this paper we will elaborate on the lessons learnt and the possibilities discovered when developing the RSD Tug 2513 and the RSD Tug 2513 CNG, which could lead us into a cleaner, safer and more cost-effective future.

Management of Environmental Impact Associated with Military Wrecks

CAPT MORGYN DAVIES OBE, Chief Salvage & Mooring Officer, UK Ministry of Defence - Salvage & Marine Operations, UK

The paper provides an operator’s view of risk management when dealing with military wreck sites and examines some of the risks and hazards likely to be experienced, based on practical observations across a wide range of operations over a period of years. It considers the aspects of wreck management specific to military equipment, covers ships and aircraft wreck sites, considers ownership, location, identification, mapping and management. It is based on lessons identified from a range of operations and provides feedback from most recent operations. It indicates what procedures are in place within the UK Ministry of Defence (MoD) to deal with operations of this type. It suggests a number of lines of development being explored by the MoD to address the issue of the environmental management of legacy wrecks. It explores a number of case studies, both ships and aircraft, and identifies some of the hazards and the mitigation measures put in place.

One-to-One Interview with Mike Allen

TODD BUSCH, Sr Vice President & General Manager, Technical Services, Crowley Maritime Corporation, USA

The Marine Insurance Market and How it Impacts on the Towage Industry

SIMON SWALLOW, Chief Executive, The Shipowners’ Club, UK

Shipowners’ P&I Club have been attending, and presenting at ITS for a number of years. Previously we have tried to address the complex nature of the liabilities that flow from either an offshore or harbour towage operation and particularly the impact that the changing contractual environment can have on the industry. We have in the past discussed ways in which tug operators can seek to avoid such liabilities or how insurance solutions can be constructed. Nonetheless, what we believe remains an important part of the jigsaw is for owners and operators to have a better understanding of the current marine insurance market and how it impacts on the towage industry. The marine insurance market is constantly changing. Currently we are experiencing very soft market conditions with increasing capacity and therefore enhanced competition in the sector. This has the added advantage of driving down premiums, but does this also mean owners receive the same quality of service from either existing or alternative insurers? Will insurers start to compromise on the settlement of claims if they see the general erosion of premium levels coupled with an increasing litigious environment? Likewise, there is an essential role for underwriters to understand the risks associated with the towage industry. Insurers need to mould the cover to meet increasing liabilities and to address the additional contractual risks. Are underwriters experienced and ready? Owners also need to establish a better understanding of the alternative insurance arrangements available that sit outside of the traditional home for shipowners’ legal and contractual liabilities, for example, insurers outside of the International Group of P&I Clubs. Whether it is a tug going to a vessel in distress, or operating in a salvage capacity, the extent to which the salved vessel is insured with an insurer that may fall outside of the International Group needs to be considered at the time of fixing a contract. What security can be given to the salvor from the insurers? What additional challenges does this create for the salvor? Likewise when a vessel is being towed, what checks are taken by the tug operator to ensure that the towed vessel is adequately insured? As it becomes an increasingly competitive shipping market with falling oil prices leading to cancelled contracts or reduced charter rates owners will inevitably start to look outside of the traditional insurance markets for cheaper options. What options are available and how reliable are they? It is important that owners are aware of the markets available through alternative insurance vehicles and not least consider the essential role that their insurance broker plays in the whole insurance process. It remains an ever changing marine insurance market and owners involved in the towage and salvage industry need to be up to speed with these changes aware as to how it can impact on their business. Let’s try to strip out the various issues and address each.

Promises Fulfilled - A Newly Completed Tug Fleet Expansion Programme for Tianjin Port

JUNKUI XIONG, Deputy General Manager, Tianjin Port Tugboat and Lighter Company Ltd, China

XUHUI (BILL) HU, Senior Naval Architect, Robert Allan Ltd, Canada

As one of the largest ports in China, Tianjin Port initiated a programme to expand its tug fleet in 2011. Five ice strengthened tugs of three different designs were developed and constructed. The programme claimed successful completion with the deployment of the last of these tugs in early 2015. This paper describes the operational requirements for the new ship-assist tugs due to the specialised nature and operational modes of the port, and also reviews the development of the entire process from functional determination, planning, design, construction, through acceptance trials, and finally to feedback on the operation of all the tugs.

Low Speed Tractor/ASD Tug Escort

CAPT GRANT LIVINGSTONE, Pilot, Jacobsen Pilot Service Inc, USA

With the advent of high speed escort ship assist work, the towing industry has witnessed and experienced new dangers. In response, naval architects and the towing industry are adapting and incorporating very effective hydrodynamic hull design and propulsion innovations to counter the dangers of tripping under high speed escort. But are these dangers really new? Has a technological evolution in tugboat operation and design left critical towing knowledge astern? Many top tier towing companies will counter that tripping and capsizing accidents are not occurring in their ranks, yet when queried off the record, are the first to admit witnessing a generational loss of conventional towing skills.

EDDY Tug - Looking Back While Moving Forward

BALDO DIELEN, Partner, EDDY Tug, Brazil

WALTER VAN GRUIJTHUIJSEN, Managing Director, EDDY Tug BV, The Netherlands

The first two years of operational experience with the EDDY30-65 tug, including performance aspects, fuel economy, client feedback and lessons learned, will be discussed, as well as the experiences with the EDDY Tug full mission bridge simulator. To bridge from the past to the future, the main features of a new tug currently under construction will be described: the EDDY 24-75. To conclude, future developments related to safety and energy efficiency will be disclosed.

Report

The need to improve standards of safety within the tug industry was the major recurring theme of the 24th International Tug, Salvage & OSV Convention (ITS), held in Boston between 23 and 27 May 2016.

Delegates were welcomed by The ABR Company chairman Allan Brunton-Reed who said: "Once again we have a very impressive attendance with delegates and exhibitors coming from all corners of the globe."

The opening keynote address was delivered by American Waterways Operators’ president and CEO, Tom Allegretti, who also gave the inaugural address in Seattle in 1996. ITS last visited the United States in 2004 when the event was held in Miami.

In Boston, he said: "Our industry’s safety journey over the past quarter-century has been nothing short of remarkable. We are a better, safer industry with a dramatically reduced environmental footprint. Coast Guard casualty statistics testify to this fact, showing significant, measurable declines across the whole array of safety metrics: crew fatalities, personal injuries, oil spills and vessel casualties."

Along with various aspects of safety and upcoming environmental legislation, papers presented at the event focused on technical innovations, best practice, lessons learned and inspirational ideas and thoughts on what are likely to be momentous changes in the tug, salvage and offshore sectors in the not-too-distant future - all against a continuing backdrop of an extremely tough economic climate.

Among the high-profile speakers were: Rob Allan, executive chairman of Robert Allan Ltd; Tom Guldner, president of Marine Firefighting Inc; Govinder Singh Chopra of SeaTech Solutions; John Witte Jr of Donjon Marine, who is also president of the ISU; Andres Banck of Caterpillar Marine and Roland Schwandt and Stefan Buch of Schottel.

At ITS 2014 in Hamburg, the programme included a one-to-one Q&A session between conference chairman Mike Allen and Costa Concordia salvage master Nick Sloane. The format proved extremely popular and so, at ITS 2016, there was a similar high-profile exchange between Mike and Todd Busch, senior vice president and general manager, technical services, Crowley Maritime Corporation. Busch is also chairman of the board at newly-formed Ardent.

"At the convention, there was a diversified group of people from all parts of the world, in a wide variety of the tug and offshore/salvage environments. Getting to network with some of the delegates was an experience you could not achieve anywhere else but at this conference."

Craig Williams, Riverside Marine

"Without doubt, attending ITS is an important strategic undertaking that has always proven a wise choice."

Capt Arie Nygh, SeaWays Consultants

There were more than 100 stands from more than 40 countries in the exhibition area where companies displayed state-of-the-art technologies and designs and took the opportunity to showcase a diverse range of products to the top-level decision-makers and industry leaders attending the event.

As at previous ITS events, companies chose to use the exhibition hall to make significant announcements about business developments and contracts.

Maritime training company SeaWays and classification society ClassNK toasted their new partnership with champagne when they announced that ClassNK was in the process of assessing, with a view to certifying, SeaWays training programmes - the first such classification aimed at setting high-level standards of safety and technical skills which both organisations are hoping will be mirrored throughout the industry.

Capt Naoki Saito, manager of ClassNK’s certification service planning department, said: "With this co-operation in tug master training, we are looking to further contribute to the safety of tug and salvage operations."

Neil Sadler, contract director of SeaWays Europe, said: "We believe that bespoke training is necessary for different classes of vessel. With high-powered tugs you cannot be complacent about competence. That is why we have decided to work towards making things safer."

Caterpillar Marine and Svitzer Europe signed a contract at ITS that will see Caterpillar using state-of-the-art technology to monitor data from Svitzer’s entire European fleet to maximise operational efficiency and spot any need for mechanical adjustments before they become a more major and more costly problem.

Rob Bradenham, global sales and business manager, Caterpillar Marine Asset Intelligence, said: "Asset intelligence is harnessing technology and services for using data from different systems on board to help owners and operators get more out of assets, avoid downtime and decrease operating costs. We can identify issues before they become a big problem. We also help owners understand how their vessels are being operated to enable them to utilise their entire fleet in an optimum way. A modern diesel engine, for example, may have around 100 sensors on it.

"We collect data from the sensors attached to engines, generators and propulsion units - everything from gas turbines to simple pumps. We focus on tailoring implementation to individual vessel types.

"We’re working with Svitzer Europe to figure out how it can incorporate this knowledge into its business. It’s not all about technology, it is also about how vessels are operated by their crew. We have senior-level buy in and will work with both on board crews and on shore tech’ teams.

"In the past those on board may have thought that there was a problem developing, but would have to wait for on shore support. Now both can have instant access to information about how the vessel is performing."

"I thoroughly enjoyed the papers’ content and presentation and the social side was fantastic."

Kent Stewart, Maritime Contractors.

"It was a good opportunity to understand trends and concerns in the industry and to network with many key players."

Corey Parker, Caterpillar Marine.

The ABR Company is grateful to the generous sponsors who helped make ITS 2016 Boston such a special event. Samson sponsored the delegate bags and registration as visitors arrived.

Damen hosted the popular invitation-only ITS Golf competition and the harbour-side Welcome Cocktail Party.

Uzmar sponsored the delegate and exhibitor lunches throughout the event, and Armon hosted Happy Hour in the exhibition hall at the close of the first day of the event.

Cashman Equipment hosted a quintessentially Boston evening at the House of Blues, which included the chance for delegates to enjoy a large slice of Americana at a Red Sox baseball game at the iconic Fenway Park stadium.

The conference’s formal business sessions ended on the afternoon of Thursday 26 May, but the social calendar continued that evening with the hugely popular Gala Dinner, a sumptuous four-course meal followed by dancing until midnight, sponsored by Caterpillar.

The Shipowners’ Club and Sanmar were joint sponsors of the next day’s boat tour taking in the historic sights of Boston Harbour, including a visit to Luna, the last surviving, full-sized, wooden ship-docking tug on the US Gulf and Atlantic coasts.

"It was a great choice of venue and had the usual attention to detail from ABR, good networking opportunities, good food and social arrangements."

Nigel Hartley, British Marine

"ITS remains the prime event to meet and mingle with people within the industry."

Richard Janssen, SMIT Salvage

After such a positive response to ITS 2016, there is already much eager anticipation about the ITS 2018 convention, and planning for that event is already underway.

"A good event … a real chance to generate future business."

Daan Merkelbach, manager tug training and consultancy, Kotug International

"An excellent high profile attendance."

Walid Elmallah, Al Masaood

"An excellent meeting place for the worldwide tug industry as always."

Steve Dougal, Century Marine

"This is the show to beat!"

Kim Cleggett, IMS