TUGNOLOGY '17

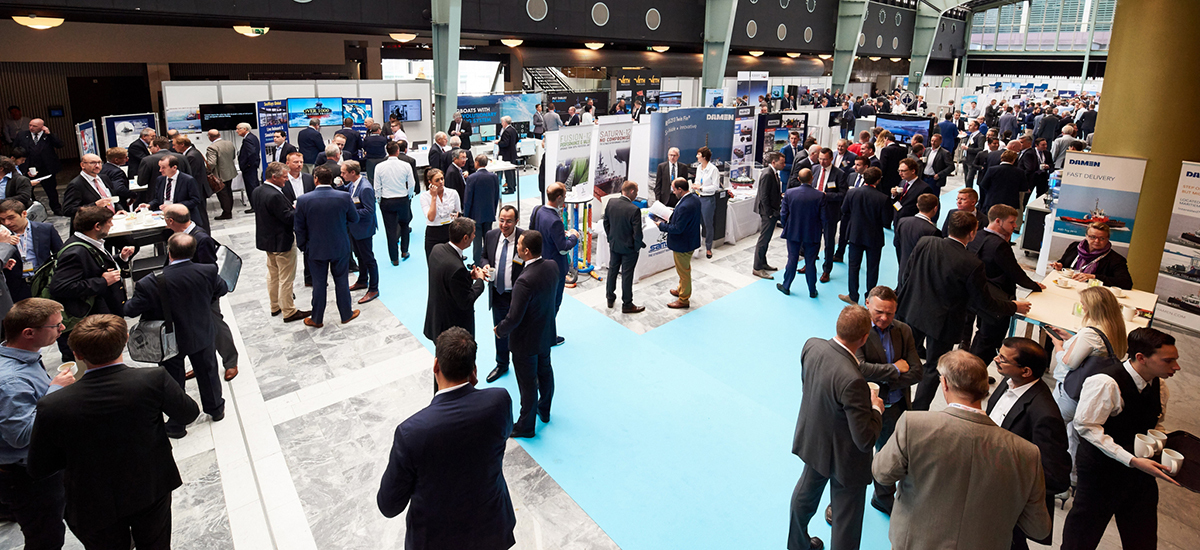

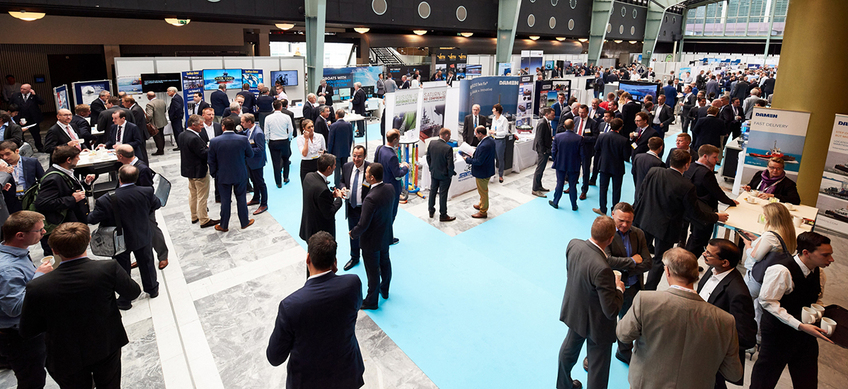

The largest Tugnology to date took place in Rotterdam as a record 392 delegates from 34 countries registered for the two-day conference in the city’s World Trade Centre, marking the 10th anniversary of the event.

The largest Tugnology to date took place in Rotterdam as a record 392 delegates from 34 countries registered for the two-day conference in the city’s World Trade Centre, marking the 10th anniversary of the event.

Papers again covered a wide range of tug-specific topics including stability, latest developments in propulsion, the increasing use of CFD in tug design, remote monitoring, engine management and reducing environmental impact.

A recurring theme through many of these papers was the importance of safety – a subject that this year saw a new format to the conference in the shape of a forum on the challenges of tug safety. Chaired by Robert Allan, the forum comprised of a panel of industry stalwarts fielding a range of questions from delegates – asked in person from the floor or via the Tugnology Web App, another new innovation for this year. The result was a lively and informed discussion.

The event began on Monday 22 May with a welcome reception hosted by Rotortug and JonRie InterTech on Kooren Terminal, a state-of-the-art maritime event pontoon on the Rotterdam quayside. This informal networking opportunity also included an appearance by RT Borkum, the Robert Allan Ltd designed new training Rotortug, the ART 10-15. After a demonstration to show off its dexterity and manoeuvrability, the vessel was moored alongside the Kooren Terminal throughout the evening allowing delegates to go on board for a viewing and guided tour.

One notable absentee from Tugnology ’17 was chairman of The ABR Company, Allan Brunton-Reed. It was the first time Allan had been unable to attend either a Tugnology or ITS event, a record dating back to the first ITS conference in 1969. Garth Manson, managing director of The ABR Company, therefore stepped into the limelight to officially open the event on Tuesday 23 May and welcome the many returning delegates as well as plenty attending their first Tugnology. Garth then handed over to René J de Vries, State Harbour Master for the Port of Rotterdam, who gave the inaugural address.

In addition to the conference, the event included an exhibition with 55 companies – another Tugnology record – taking part, featuring several deals and other announcements over the two days. These included the signing of a contract for a Bogacay Class tug between Turkish shipbuilder Sanmar Shipyards and UK-based Targe Towing; a contract between another Turkish shipyard, Uzmar, and naval architects Robert Allan Ltd for three exclusive new-design tugboats; and a presentation to mark the 1,000th tug designed by Robert Allan Ltd.

Key to making Tugnology a success are the many sponsors who work with The ABR Company. This year, MTU were responsible for the delegate bags. The company also sponsored the tea and coffee breaks, while Uzmar Workboat & Tug Factory sponsored lunch on both days, ensuring delegates were kept refreshed throughout the conference.

On the Tuesday evening, the conference hall was transformed for the event dinner, sponsored by Damen, with the pre-dinner drinks sponsored by Samson. Both the dinner and drinks reception were further opportunities for informal networking and catching up with old friends.

The official photographer in attendance for the duration of the event was sponsored by Caterpillar. For energetic early-birds, morning runs along part of Rotterdam’s attractive waterside were organised by IMS.

Feedback from delegates has been very positive, with 95% of attendees giving Tugnology ’17 an overall rating of excellent or good. Here is a selection of some of the many comments:

“Every year it amazes me that you can bring the entire world tug community together in one location.”

Joop Timmermans, Port Towage Amsterdam BV

“Excellent event for meeting people in the tug industry.”

Leslie Lee, Hong Kong Salvage & Towage

“Excellent experience and I recommend it to others.”

Walid Elmallah, Al Masaood

“It was well worth us attending this event. The papers presented were quite interesting and the social evenings were well organised.”

Raymond Bartolo, Tug Malta Ltd

“Nucleus of the tugboat industry. The right people at the right place. Good mixture of presentations and time for networking.”

Dr Matthias Schlipf, MAN Diesel & Turbo SE

“The organisation of the conference was excellent. The subjects of the papers were very interesting and useful.”

Arnaldo Calbucci, Wilson, Sons

“Tugnology ’17 provided us opportunity to see, communicate and networking with most of tug related persons in our sector. It also gives us chance to follow developments, experiences and explorations in tug boat business.”

Bilgehan Acerer , Bogazici Denizcilik AS

The feedback is also valuable in terms of what can be done differently at Tugnology ’19, planning for which has already begun.

About TUGTECHNOLOGY

TUGTECHNOLOGY is a two day event consisting of a conference programme, exhibition and gala dinner. It is the industry’s premier technical gathering.

TUGTECHNOLOGY brings together the global tug owning and operating community, the international supply chain and the sector’s industry associations and regulators for two days of networking, intelligence gathering and deal making in a warm, welcoming and professional setting. The conference programme is known for its technical range and depth and as the forum to analyse, discuss and debate the very latest concepts and advances. Papers are vetted by an expert industry advisory panel and competition to present is intense.

TUGTECHNOLOGY is organised by Riviera Maritime Media, the team behind the ITS conventions and International Tug & Salvage magazine.

Report

The largest Tugnology to date took place in Rotterdam as a record 392 delegates from 34 countries registered for the two-day conference in the city’s World Trade Centre, marking the 10th anniversary of the event.

Papers again covered a wide range of tug-specific topics including stability, latest developments in propulsion, the increasing use of CFD in tug design, remote monitoring, engine management and reducing environmental impact.

A recurring theme through many of these papers was the importance of safety – a subject that this year saw a new format to the conference in the shape of a forum on the challenges of tug safety. Chaired by Robert Allan, the forum comprised of a panel of industry stalwarts fielding a range of questions from delegates – asked in person from the floor or via the Tugnology Web App, another new innovation for this year. The result was a lively and informed discussion.

The event began on Monday 22 May with a welcome reception hosted by Rotortug and JonRie InterTech on Kooren Terminal, a state-of-the-art maritime event pontoon on the Rotterdam quayside. This informal networking opportunity also included an appearance by RT Borkum, the Robert Allan Ltd designed new training Rotortug, the ART 10-15. After a demonstration to show off its dexterity and manoeuvrability, the vessel was moored alongside the Kooren Terminal throughout the evening allowing delegates to go on board for a viewing and guided tour.

One notable absentee from Tugnology ’17 was chairman of The ABR Company, Allan Brunton-Reed. It was the first time Allan had been unable to attend either a Tugnology or ITS event, a record dating back to the first ITS conference in 1969. Garth Manson, managing director of The ABR Company, therefore stepped into the limelight to officially open the event on Tuesday 23 May and welcome the many returning delegates as well as plenty attending their first Tugnology. Garth then handed over to René J de Vries, State Harbour Master for the Port of Rotterdam, who gave the inaugural address.

In addition to the conference, the event included an exhibition with 55 companies – another Tugnology record – taking part, featuring several deals and other announcements over the two days. These included the signing of a contract for a Bogacay Class tug between Turkish shipbuilder Sanmar Shipyards and UK-based Targe Towing; a contract between another Turkish shipyard, Uzmar, and naval architects Robert Allan Ltd for three exclusive new-design tugboats; and a presentation to mark the 1,000th tug designed by Robert Allan Ltd.

Key to making Tugnology a success are the many sponsors who work with The ABR Company. This year, MTU were responsible for the delegate bags. The company also sponsored the tea and coffee breaks, while Uzmar Workboat & Tug Factory sponsored lunch on both days, ensuring delegates were kept refreshed throughout the conference.

On the Tuesday evening, the conference hall was transformed for the event dinner, sponsored by Damen, with the pre-dinner drinks sponsored by Samson. Both the dinner and drinks reception were further opportunities for informal networking and catching up with old friends.

The official photographer in attendance for the duration of the event was sponsored by Caterpillar. For energetic early-birds, morning runs along part of Rotterdam’s attractive waterside were organised by IMS.

Feedback from delegates has been very positive, with 95% of attendees giving Tugnology ’17 an overall rating of excellent or good. Here is a selection of some of the many comments:

“Every year it amazes me that you can bring the entire world tug community together in one location.”

Joop Timmermans, Port Towage Amsterdam BV

“Excellent event for meeting people in the tug industry.”

Leslie Lee, Hong Kong Salvage & Towage

“Excellent experience and I recommend it to others.”

Walid Elmallah, Al Masaood

“It was well worth us attending this event. The papers presented were quite interesting and the social evenings were well organised.”

Raymond Bartolo, Tug Malta Ltd

“Nucleus of the tugboat industry. The right people at the right place. Good mixture of presentations and time for networking.”

Dr Matthias Schlipf, MAN Diesel & Turbo SE

“The organisation of the conference was excellent. The subjects of the papers were very interesting and useful.”

Arnaldo Calbucci, Wilson, Sons

“Tugnology ’17 provided us opportunity to see, communicate and networking with most of tug related persons in our sector. It also gives us chance to follow developments, experiences and explorations in tug boat business.”

Bilgehan Acerer , Bogazici Denizcilik AS

The feedback is also valuable in terms of what can be done differently at Tugnology ’19, planning for which has already begun.

Programme

Opening and Inaugural Address

RENÉ J DE VRIES, State Harbour Master, Port of Rotterdam Authority, The Netherlands

Enhancing Tug Safety Through Internationally Harmonised Stability Regulations

GIJSBERT DE-JONG, Director Offshore Service Vessels & Tugs, Bureau Veritas Marine & Offshore, The Netherlands

Following the release of the Bureau Veritas Safety Guidelines for Design, Construction and Operation of Tugs at ITS 2014 in Hamburg, a push has been made to bring the newly developed stability requirements up to the level of the International Maritime Organization (IMO) in London. In 2016, IMO adopted the amendments to the 2008 Intact Stability (IS) Code, which include stability criteria for towing and escorting based on the Bureau Veritas guidelines. This is a major milestone in the development of a -- much needed -- internationally harmonised standard to enhance tug safety and provides a clear answer to issues raised by the industry, including at ITS 2016 in Boston.

Future-oriented Developments in Azimuth Thruster Technologies

JACOB BRYJA, R & D Calculations, Schottel GmbH, Germany

Propulsion systems like the Schottel Rudderpropeller are high-end products with state-of-the-art technology contained in every mechanical element. They incorporate the latest materials, a power train design with high-performance bevel gears and bearings, and are designed using simulation methods for structural and hydrodynamic calculations (such as the finite element method, computational fluid dynamics and multibody simulation), as well as further efficiency approaches through operation point optimisation. In particular, the power train has been continuously improved to reach higher power densities than ever before. Materials used for bearings and gear sets come with the highest fatigue limits and are the best quality available. As the bevel gear is the size-determining element within the upper and lower gearboxes of an azimuth thruster, there is a significant trickle effect onto many downstream features of the overall system. The smaller the bevel gear, the smaller the housing around it, and for the underwater part of the thruster this means improved hydrodynamic properties, leading to a better propeller-to-housing ratio and therefore better efficiency. Every manufacturer of propulsion systems has its own know-how, and with increased technical opportunities the challenge to make the best products using the given resources has grown over the past decades. As part of its research programme, Schottel has developed a unique and major improvement of a key element within the azimuth thruster: a new type of bevel gear which comes with a unique gearing geometry never used before, and which has a significantly increased load capacity.

Using CFD in the Design of Modern Ship Handling Tugs at Damen

JOCHEM DE JONG, Principal Research Engineer Hydromechanics, Damen Shipyards, The Netherlands

JOOST SCHOT, Research Engineer, Damen Shipyards, The Netherlands

Within the tug industry the use of computational fluid dynamics (CFD) is increasing. CFD can provide tug designers with a full description of the flow around the tug. Commercial CFD tools from various suppliers are considered very robust nowadays, as the software always provides the user with an answer, even for complex geometries and conditions. However, robustness should not be mistaken for accuracy, especially for complex flows such as found in drift simulations reflecting an escort equilibrium. It is generally known that verification and validation of the solution is absolutely necessary to quantify the numerical and modelling errors involved in the CFD simulations. This paper discusses the results of research conducted at Damen, containing extensive verification and validation studies of CFD simulations on tugs for both the resistance and drift conditions. Examples are given of how Damen implements these techniques to increase knowledge and improve TugSim, the in-house developed tool to quantify the towing performance of Damen tug designs.

Remote Monitoring - Bridging the Technology Gap between Workboat Operations and Other Industries

DR MATTHIAS SCHLIPF, Head of Sales & Project Manager High Speed, MAN Diesel & Turbo SE, Germany

MARK WATSON, Sales & Sales Support Engineer, MAN Diesel & Turbo SE, Germany

Having real time data on important equipment during workboat operations has already proven to be beneficial to owners, ensuring that a high level of safety and efficiency is achieved. Collecting and analysing such ’big data’ using the latest technologies, and thereby understanding equipment performance, allows for operational fine tuning. It can also provide significant benefits in areas such as life-cycle cost improvement, safety, planned maintenance, performance benchmarking, emissions reduction, key component wear rates and long term equipment reliability improvements by OEMs. This paper investigates today’s capabilities, and considers how these technologies - already well established in other similar B2B industries such as turbomachinery, power plants and commercial vehicles - can be harnessed more extensively in the marine workboat sector.

A New Propulsion Family for Tugboat Applications

EDGAR SNELDERS, General Manager Product Platform Thrusters, Wärtsilä Netherlands BV, The Netherlands

This paper introduces a new family of steerable thrusters to the tugboat business, bringing solutions to the current needs of the market and covering multiple applications. The key values of the new design are: high overall efficiency, high manoeuvring capability, reliability and advanced system integration. The thruster family is designed and validated following a rigorous engineering process, including full scale testing under controlled conditions. The first commercial applications in an LNG tug and an OSV have been installed at the shipyard.

The Challenges of Tug Safety

CAPT ARIE NYGH, Managing Director, SeaWays Consultants Pty Ltd, Australia

ROBERT ALLAN, Executive Chairman, Robert Allan Ltd, Canada

DIRK DEGROOTE, Product Manager - Tugs, Damen Shipyards, The Netherlands

CAPT CARSTEN NYGAARD, Group Marine Manager, Svitzer AS, Denmark

The Advantages of a Low-emission Hybrid E-tug, Driven by a Revolutionary Podded Drive with Flexible and Green Diesel-electric Configuration

HAIJO VAN DER WERF, Business Development Manager, Offshore Ship Designers BV, The Netherlands

WALTER VAN DER PENNEN, Portfolio Manager Hybrid Energy, RH Marine Netherlands BV, The Netherlands

The use of greener harbour tugs is becoming ever more important to both contractors and authorities. As a result of new emission rules, the expansion of Emission Control Areas (ECAs), stricter local regulations, public opinion and the need for sustainability, Offshore Ship Designers (OSD) undertook to design a new energy efficient -- and therefore a low emission -- e-tug. Our original concept, in 2010, was based around hydrogen power and the use of a fuel-cell. Unfortunately, this technology has yet to be proven mature, and as of 2017 this solution is not yet available for high-power marine use. As a result, OSD worked on a design using a podded drive with a flexible diesel-electric configuration.

Full Electric vs Hybrid - Refit and Newbuild Design Considerations

BRENT PERRY, CEO, PBES, Canada

Hybrid solutions have now been accepted as mainstream propulsion technology in a variety of vessel types, due to their increased efficiency and lower operating costs. However, most systems today are being sold with a 10-year or more lifespan. Designing a battery to meet a 10-year mission is difficult due to the variety of different discharge rates and other variable criteria that must be accounted for. This leads to a tendency for the system designer to oversize the system capacity and ensure the batteries stay within ’gentle use’ parameters. This paper will address the technical considerations for reducing battery size and battery re-coring. Operational profiles which are best suited for the use of this technology and safety considerations will also be discussed.

A World-first Configuration - a Dual Fuel Engine Direct Coupled with an FPP Z-Peller on a Harbour Tug

HIDEYUKI TAKAHASHI, Marine Engineering, Niigata Power Systems Company Ltd, Japan

DAIKI IKEDA, Manager, Regional Marketing & Sales, Niigata Power Systems (Singapore) Pte Ltd, Singapore

To meet emission regulations for marine engine (that become more restrictive, year on year), the use of the alternative fuels is growing. GAS fuels, typified by natural gas, are in high demand, as it outperforms liquid fossil fuels in terms of measures to counter greenhouse gases, acid rain and soot dust. In response to these trends, Niigata Power Systems has developed the 28AHX-DF dual fuel engine, featuring revolutionary characteristics. The target for this engine is harbour tugboats with directly driven propellers, especially fixed pitch (FP). The engine that can tolerate the rapid load change operation by leveraging advanced combustion technology and air-fuel ratio control technology. It was delivered to a tugboat as a main engine in January 2015, then operated over a one year period in Tokyo bay from September 2015. Taking advantage of good transient property, it is possible to use this engine not only as a main engine for tugboats but also for research vessels, cargo carriers and ferries, as well as auxiliary engines for large container vessels. This paper describes the performance and technology of the 28AHX-DF engine and the results of its one-year tugboat operation.

Increased Safety and Reduced Lifecycle Costs with Electronic Diesel Engine Management

CYRILL HALBAUER, Application Engineer, MTU Friedrichshafen GmbH, Germany

SEBASTIAN SCHWARZ, Application Center Marine Commercial Vessels, MTU Friedrichshafen GmbH, Germany

This paper demonstrates the potential for modern electronic control systems to enhance the operation of high speed marine diesel engines, thereby optimising their performance and the operational safety of the vessels in which they are used. We aim to demolish the myth that engine electronics unnecessarily add to the complexity of tug propulsion machinery. In addition, the paper should assist in understanding why electronic management systems are indispensable to meet current and future emissions legislation, reduce lifecycle costs and simplify both scheduled and unscheduled engine maintenance. Furthermore, we discuss the benefits of close interaction between the engine electronics and ship automation systems. Finally, the paper highlights progress in the field of electronic marine engine management on the basis of 20 years of MTU Series 4000 engine development.

Stern Flow Stabilisation to Improve Directional Stability of Tugs with Low Length-to-Beam Ratios

BARTON STOCKDILL, Technical Manager Hydrodynamics, Robert Allan Ltd, Canada

The trend towards compact, high power ship-handling and escort tugs is pushing naval architects to design hulls with lower length-to-beam (L/B) ratios. Hydrodynamic design with low L/B ratios to achieve good directional controllability while running free can be challenging, particularly for tractor tugs. Flow separation at unavoidably bluff sterns can cause directional instabilities from vortex shedding and the fluctuating yaw moments that accompany it. This is known as vortex induced motion (VIM). These instabilities can be reduced by adding larger skegs aft; however, this is only effective while running ahead. Larger skegs can have a destabilising effect when running astern, and also have the potential to interfere with thruster wash. Astern performance is particularly important for Advanced Voith Tractor (AVT) tugs, which are designed to carry out escort operations while running astern at speeds of up to 12 knots. This paper discusses state-of-the-art computational fluid dynamics (CFD) and model testing techniques that have been developed to evaluate the directional stability response of low L/B tractor tugs to vortex induced motion. These techniques have been used to develop novel devices called StRAke stabilisers, which substantially improve directional controllability by controlling flow separation at the stern with a minimal increase in drag and no increase in skeg size. StRAke stabilisers (referred to as StRAkes hereafter) have been successfully installed and tested on the new TRAktor 3000-V and the TRAktor 3200-V, both of which are high performance AVT tugs designed for ship-handling duties in harbour and escort duties at sea. Both tugs are under 500grt and are nominally capable of generating 70 tonnes of bollard pull and 100 tonnes of escort steering force at 10 knots.

Next Generation Performance-Linked Tug Stability

GOVINDER SINGH CHOPRA, Director, SeaTech Solutions International (S) Pte Ltd, Singapore

There is a general consensus that the present IMO stability criteria are not adequate for tugs and other workboats. Having established the limitations of present IMO stability criteria, there is an urgent need to raise the bar and develop better guidance for the tug master and operators. This paper introduces a limiting operability envelope approach to tug stability, together with practical methods of assessing and monitoring stability during operations. The following parameters have been identified that can be readily measured, and which also lend themselves to the judgmental perception of safety by the operators for each mode of operation: heel angle, ship speed, rudder or azimuth angle, and wind speed and direction. Limits for these parameters are obtained from the modified IMO criteria, and these can be monitored onboard. In this paper, a case study is used to illustrate the performance-based stability approach.

Going Green while Staying Lean

JONAS L NYBERG, Product & Development Manager, Caterpillar Marine Solution Center, Sweden

The IMO and other regulatory bodies oblige ship owners to invest in environmentally-friendly engine and exhaust after-treatment technology to reduce SOx and NOx emissions, seemingly irrespective of the cost or operational complexity of the equipment concerned. With the entry into force of new rules still being phased in, and the technology to meet the restrictions still developing, Caterpillar believes that it is critical that tug owners consider alternative power plant combinations to ensure compliance at lower overall cost. In this paper, Caterpillar offers a methodology to identify a route to compliance for tug owners and operators that dispenses with non-viable technologies and arrives at a solution which -- over time -- achieves the lowest total cost of ownership. Caterpillar explores the technical options facing a prospective investor in two specific newbuild tug projects, assessing the propulsion plant for both vessel types in detail from the perspective of capital expenditure (Capex) and operating expenditure (Opex), based on compliance with IMO air emissions restrictions. After considering candidate power and propulsion solutions, it becomes clear that a ’bottom up’ methodology based on operational requirements offers the best guidance for evaluating and comparing the different proposed solutions.

Your Oil is Talking - But Are You Listening? Controlling and Monitoring Oil Contaminants on Tugs

KIM KJAER, Global Segment Manager, Marine & Offshore, CC Jensen AS, Denmark

STEFFEN D NYMAN, Corporate Trainer & Consultant, CC Jensen AS, Denmark

As modern tugs have evolved, so has the lubrication of these systems. Today, increasing demand is put upon lubricants in terms of operating temperatures, loads and performance. The oil film over components is only a few microns thick, invisible to the human eye, and it is therefore essential to control and monitor contamination effectively. It is well established that cleaner oil leads to longer component lifetimes and increased operational liability, but clean oil also means that an operator can detect small changes in both online and laboratory analysis, thereby often detecting abnormal wear before a breakdown.