Business Sectors

Events

Ship Recycling Webinar Week

Contents

Is Now the Time to Consider Switching to Shaft Power Meters and ShaPoLi for EEXI Compliance?

One of the critical pieces of equipment required to measure ship performance is a shaft power meter. These devices measure the true power being delivered along the shaft to the propellor, which is very different to the indicated power calculated by the engine PMI system, by measuring cylinder pressure.

Most ships currently in operation that needed to comply with the Energy Efficiency Existing Ship Index (EEXI) rules for limiting engine power have completed the necessary modifications. As a result, the industry has adapted to operating under these new regulations, where engine power has been limited to reduce carbon emissions.

Ship owners and operators could choose between the following two methods for EEXI compliance:

Engine Power Limitation (EPL) where the engine power is limited through a physical device on the governor to restrict fuel flow to the engine (for mechanical engines) or through a software upgrade in the engine control system for electronic engines.

Shaft Power Limitation (ShaPoLi) on the other hand, offers a different approach, where power is measured by a shaft power meter and is connected to an alarming device on the bridge. This device is activated when the measured power exceeds for the engine’s EEXI limit. Unlike the EPL method, the engine under ShaPoLi does not have any limiting device fitted. This method, with its unique features, is gaining traction among ship operators.

As operators gain experience in managing engine performance and compliance with this regulation, some have identified that the EPL method poses operational and safety challenges, especially for ships with mechanical engines and significant power restrictions where engine responsiveness and performance during critical situations can be compromised. Consequently, some owners are switching from EPL to ShaPoLi systems. Duncan Gaskin, Technical Sales Manager, Trelleborg Marine and Infrastructure discusses some of the reasons behind this shift and highlights how fitting a ShaPoLi system can help ships mitigate the operational and safety hazards linked to the EPL method.

U.S. Coastguard (USCG) Policy Directive 01-24

The U.S. Coast Guard (USCG) introduced a new policy directive (16670 CG-ENG Policy Letter 01-24) in April this year, requiring ships with an EEXI compliance method to “override” the system while operating in U.S. waters. Several maritime industry reports suggest that this directive may be a proactive response to the Baltimore bridge accident in March this year, which likely raised concerns about ships fitted with engine power limitation devices for EEXI compliance.

The policy directive gives guidance to Captains of the Port (COTPs), Officers in Charge of Marine Inspection (OCMIs), and maritime stakeholders as to how these devices could affect the maneuverability characteristics of ships and compliance with U.S. Federal Regulation 33 CFR §164.11(k), for the safe navigation of ships operating in U.S. waters. Additionally, the directive also references SOLAS Chapter V Regulation 34, which mandates safety-focused voyage planning, including the following considerations for safe voyage planning especially when a power limiting device is installed:

- Number, severity, and frequency of course and speed changes necessary to safely navigate in a river or restricted waterway.

- Duration of transit in restricted waters.

- Density of commercial and recreational marine traffic.

- Tug availability in the port/waterway with consideration for ship needs, required tug size, and power rating.

Guidance is provided as follows:

- Ships with a permanent power modification must update pilot cards and wheelhouse posters to reflect manoeuvrability with the device installed.

- 33 CFR § 164.11 (k) requires pilots to be informed of all ship manoeuvring characteristics. If the ship’s manoeuvring characteristics indicated on the pilot card and wheelhouse poster were not updated following the installation of an EPL/ShaPoLi system, the ship is not in compliance with this regulation. As such, the system or program must be overridden prior to entry into U.S. territorial waters.

The override procedure must be completed well in advance of when it is deemed necessary for safe operation while navigating in restricted waters. Operators are reminded that the system must be re-engaged when the ship is clear of the area or situation that required the system override.

For a full copy of the USCG Policy directive 01-24, click here.

Implications of the Policy Directive

Under this directive, any ship installed with the EPL or ShaPoLi power limitation methods, on the face of it, will no longer comply with EEXI when in U.S. waters as both systems have to be overridden. However, the policy directive clarifies that by stating “overriding the EPL/ShaPoLi to safely navigate in restricted waters does not constitute a MARPOL Annex VI violation, as these regulations do not apply to emissions necessary for securing the safety of a ship”. Thus, it can be inferred that the USCG views the use of these systems as a serious safety concern, and a compulsory override while in US waters is warranted for safety reasons.

Safety concerns for ships equipped with a ShaPoLi system are significantly lower than for those using the EPL method for mechanical engines. With a ShaPoLi system, the engine remains unrestricted and in its original condition. This means that the existing pilot cards and wheelhouse charts remain applicable even when the ship operates within its EEXI limits, as unreserved power can be accessed even without needing to override the system. To comply with this directive, the system has to be overridden and the captain can easily do that by selecting the override function on the ShaPoLi display and cancelling the EEXI alarm—a process that takes just seconds.

On the other hand, ships with mechanical engines using the EPL method are physically limited and cannot exceed the EEXI limit without removing the limiter on the governor. As a result, the existing pilot cards and Wheelhouse posters will not apply if they have not been updated. In this context, the USCG’s concerns regarding the safety of ships operating in restricted waters, with these systems are valid.

In addition to these concerns, the limiter must be physically removed to access the unreserved power to comply with the policy directive. Consequently, the crew will need to break the approved seal and remove the limiter on the governor before entering US waters, then re-fit the limiter and install a new approved seal when leaving US waters. This process may require Class to approve the re-fitted limiter and new seal. This presents a challenge for the crew and may also incur costs for the ship, as this requirement will need to be addressed every time it enters and exits U.S. waters.

For more information about how Trelleborg’s Shaft Power Meter with ShaPoLi can assist with USCG compliance: download more information here.

Wider Safety Issues of using EPL Method v ShaPoLi

The USCG policy directive has highlighted concerns regarding the safe manoeuvrability of ships in restricted waters with EPL method installed. However, additional safety issues surrounding the use of this method on mechanical engines warrant attention. Under EEXI rules, a ship can access the unreserved power in an emergency situation such as man overboard, pirates, weather, or medical emergencies. With the EPL method installed on ships with mechanical engines, one of the crew must physically remove the limiter on the governor to access the unreserved power. This process could cause a delay of 15-20mins, which conflicts with what is required in an emergency situation when unreserved power is needed immediately. While this may not be a concern for ships with minor power limitations, it poses significant risks for those ships with engines that have significant power restrictions.

In contrast, when a ShaPoLi system is fitted, the engine is not limited, allowing the unreserved power to be accessed within seconds by overriding the system through the ShaPoLi display on the bridge. Therefore, the ShaPoLi system offers a safer solution in emergency situations, ensuring both the crew’s safety and the ship’s navigation when additional power is required.

Shaft Power for Performance Monitoring

Many ship owners are looking to install performance software on their ships and in their management offices to comply with current CII and future regulations aimed at reducing carbon emissions from ships. This software can enhance ship energy efficiency under CII, reducing fuel consumption and lowering carbon emissions. One of the critical equipment required to measure ship performance is a shaft power meter. These devices measure the true power being delivered along the shaft to the propellor, which is very different to the indicated power calculated by the engine PMI system, by measuring cylinder pressure.

The measurement of “true” power is very important when making informed decisions about ship performance and operating a ship in the most efficient manner. By investing in a shaft power meter and ShaPoLi system, ships can more easily comply with EEXI and U.S. Coast Guard requirements, while also utilizing this data alongside other performance metrics for comprehensive performance evaluation. Investing in a ShaPoLi system is therefore a cost-effective compliance method, as it provides the ship with a shaft power meter that can then be used for applications beyond EEXI compliance.

For more information about how Trelleborg’s Shaft Power Meter with ShaPoLi can assist with CII improvements, download here.

Flexibility in Engine Operation

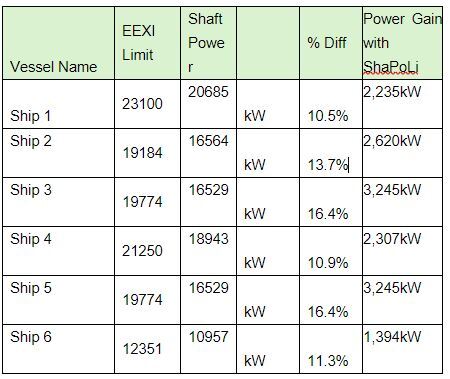

Under EEXI rules, the EEXI power limit for each engine is determined as a percentage of the measured test bed indicated engine power. In a ShaPoLi system the shaft power meter is measuring shaft power, which, as previously mentioned, is the true power being delivered along the shaft to the propellor, also referred to as power to water. Shaft power differs from indicated engine power and typically reports lower due to mechanical inefficiencies and friction losses in the engine, crankshaft, and shaft. Due to the lower power readings from the shaft power meter, fitting a ShaPoLi system provides the flexibility of additional power without exceeding the EEXI power limit.

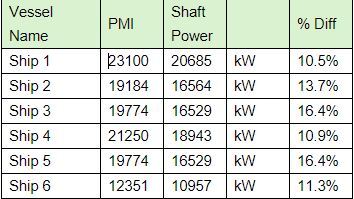

See below the engine power and shaft power readings from a number of new build container ships compared to the readings provided by the PMI.

The table shows how that shaft power meter reading is consistently lower than engine power reading measured by the PMI. For example, in the case of EEXI, if the PMI reading is adjusted to the EEXI limit for the engine, the same percentage difference will apply, which indicates the potential amount of power the ship could access without exceeding the EEXI limit, provided a ShaPoLi system is installed.

Summary

In conclusion, there are key operational and safety challenges linked to the EPL method used for mechanical engines in adherence to EEXI regulations. By installing a shaft power meter and the ShaPoLi system, these issues can be effectively addressed. Key benefits include:

- straightforward compliance with USCG Policy Directive 01-24

- immediate access to unreserved power during emergencies

- a versatile shaft power meter for broader applications beyond EEXI compliance

- enhanced flexibility in engine power within EEXI limits

Implementing the ShaPoLi method not only ensures compliance but also improves operational readiness and safety.

Trelleborg Marine and Infrastructure’s operations based in Korea manufacture the TSX5 shaft power meter that has been used in hundreds of ShaPoLi systems for EEXI compliance. To find out more about the TSX5 and ShaPoLi systems, please click here.

Related to this Story

Events

Ship Recycling Webinar Week

International Bulk Shipping Conference 2025

Tankers 2030 Conference

Maritime Navigation Innovation Webinar Week

© 2024 Riviera Maritime Media Ltd.