Business Sectors

Events

Ship Recycling Webinar Week

Contents

How new technologies help owners cut fuel costs, remain compliant

Technologies such as voyage optimisation, wind-assisted sailing, propulsion devices and air lubrication will enable vessel owners and operators to save fuel, lower emissions and remain compliant

With global and regional environmental regulatory deadlines fast approaching, maritime stakeholders must adopt proven solutions to reduce emissions. These range from implementing software to optimise voyages and ship operations, through to investing in fuel-saving devices and low-carbon fuels.

But with so many solutions available, it is difficult for shipowners and operators to select the correct decarbonisation strategy, with a risk they will be stuck with higher costs and non compliance in the future.

An expert panel discussed how owners are deploying voyage optimisation and retrofitting vessels to reduce fuel consumption and emissions during Riviera’s Decarbonisation in Practice: New Technologies and Compliance Timelines webinar, which was held in association with Sofar Ocean on 23 October 2025 during Riveria’s Vessel Optimisation Webinar Week.

On the panel were Clarksons SEA carbon analytics lead Sudharsan Rajendran, Glo Marine business development manager Soren Scheid and Sofar Ocean head of software products Dennis Rong.

Mr Rajendran described the many international and regional environmental regulations that will impact shipping over the next decade such as IMO’s plans to introduce levies on ships emitting too many emissions and the UN organisation’s carbon intensity index, plus the European Union’s emissions trading system and FuelEU legislation.

“It is becoming an economic requirement to reduce fuel consumption and emissions to remain compliant and profitable,” said Mr Rajendran.

He recommended owners work with charterers and other stakeholders to lower bunkers and emissions on ships by implementing multiple techniques and technologies.

“Jumping too early could be expensive and waiting too long means compliance complaints could rise”

This starts with improving data quality and using optimisation solutions using this information, such as hull cleaning and voyage planning, then looking at retrofitting devices to save fuel.

“From now to 2030, all will be challenged,” he said. “Jumping too early could be expensive and waiting too long means compliance complaints could rise.”

From 2028, owners need to consider transitioning to low-carbon fuels such as LNG, LPG and biofuels; retrofitting ship hulls and propulsion with fuel-saving devices; and scrapping older vessels that cannot be upgraded.

Mr Scheid spoke about retrofitting vessels with technologies in a phased scheme to reduce fuel consumption and emissions and to remain compliant with EU and IMO environmental regulations. These solutions require capital expenditure with months or years before seeing a return on investment (RoI), which should be shared between owner and charterer.

“Decarbonisation is a burden on shipping, but it is also an opportunity to save money,” Mr Scheid said.

There are several challenges to decarbonisation compliance, including finding the most suitable products for ships in a fleet with different operational performance, trading patterns and commercial arrangements.

“There are dozens of technologies to reduce CO2, but not all will be applicable to all vessel types and many are new and untested,” said Mr Scheid. “When there is pressure on compliance, waiting is not an option as it increases risk and costs.”

Mr Scheid gave a case study involving a shipmanager seeking to upgrade a Kamsarmax bulk carrier to improve its carbon intensity index (CII) rating into the mid-2030s.

“We can act like a lighthouse, showing a clear path through the decarbonisation storm”

Without applying technology, this 82,000-dwt ship would have slipped into a CII D rating in 2027 and an E rating in 2029, resulting in the owner having to scrap it seven years earlier than anticipated.

Glo Marine analysed the available technologies, simulating their impact on CII and emissions, and provided the shipmanager with a three-phased approach to keeping this 230-m ship compliant until 2035.

“We analysed the vessel’s operational profile, defined goals and the constraints of implementing new technology,” Mr Scheid explained. “We shortlisted the most promising technologies and engaged around 20 manufacturers for vessel-specific changes and performance expectations.”

Glo Marine recommended the first phase of investment in 2026 to be installing ultrasound hull and propeller protection and a propeller boss cap, at a cost of around US$460,000 to reduce fuel consumption and emissions, with RoI in 14 months. The next phase in 2029 willl see ducts and fins installed on the propulsion system at US$200,000, with nine months cost recovery. A third phase in 2031 includes installing a US$1.4M air-lubrication system on the hull to reduce friction and fuel consumption, which could take two years RoI, but extend the ship’s C-rating to 2033 and commercial life to 2035.

“We can act like a lighthouse, showing a clear path through the decarbonisation storm, and provide a road map for existing vessels,” said Mr Scheid. “Owners can spread costs, so it is not all at once, to gain peace of mind for compliance and extend the lifetime of vessels.”

Weather routeing

Voyage optimisation and weather routeing can enable shipowners and operators to reduce fuel consumption and emissions, with far less cost.

Sofar’s Mr Rong said dynamic route optimisation results in around 5-8% fuel savings on average per vessel and voyage. The company has deployed thousands of ocean sensors for more than 75% global coverage to produce weather forecasts and provide intelligence on sea conditions.

“High-quality vessel models, weather forecasts and optimised waypoint suggestions means Wayfinder helps reduce fuel and emissions during voyages,” said Mr Rong.

Weather routeing can be integrated with other decarbonisation technologies such as wind-assisted propulsion.

“We can optimise routes in real-time,” said Mr Rong. “When sails are added, this changes the dynamics of where to sail the ship, so they ride the weather and waves of storms.”

By optimising routes for ships with rotor, wing or suction sails, owners and operators can save a considerable amount of fuel, said Mr Rong.

“Over time, we can identify and develop a breakdown of fuel savings, which can be as high as 20% on certain days, depending on wind and sea conditions.”

Before owners invest in sails, they can use voyage optimisation software to simulate routes as if they had sails and determine the future benefits. These modelling programs and expert insight will help owners “get through dark forests of technologies,” said Mr Rong.

Webinar poll results

Attendees were asked to vote on a series of poll questions during the webinar. Here is a summary of the results.

Which technology category accounts for the largest capital expenditure in your near-term compliance plans?

Energy-efficiency devices: 23%

Alternative fuels: 29%

Onboard carbon capture and storage systems: 17%

Wind-assisted propulsion technologies: 19%

Digital optimisation and voyage planning tools: 12%

Which compliance mechanism presents the greatest financial risk to your fleet operations by 2030?

EU ETS allowance costs: 0%

FuelEU Maritime penalties: 54%

CII rating decline: 17%

IMO GFI levy: 25%

UK ETS exposure: 4%

How would you describe your current approach to weather routeing and performance optimisation?

Manual routeing using traditional weather services only: 19%

Digital tools without integrated performance models: 28%

Automated voyage optimisation with VPM integration: 15%

Advanced AI-driven optimisation with real-time adaptation: 20%

No systematic voyage optimisation implemented yet: 18%

How much fuel cost variance do you attribute to limitations in weather forecast accuracy in your current operations?

Less than 2% of total fuel costs: 7%

Between 2–5% of total fuel costs: 24%

Between 5–10% of total fuel costs: 10%

More than 10% of total fuel costs: 21%

Cannot quantify or measure this impact at present: 38%

(source: Riviera Maritime Media)

Related to this Story

Events

Ship Recycling Webinar Week

International Bulk Shipping Conference 2025

Tankers 2030 Conference

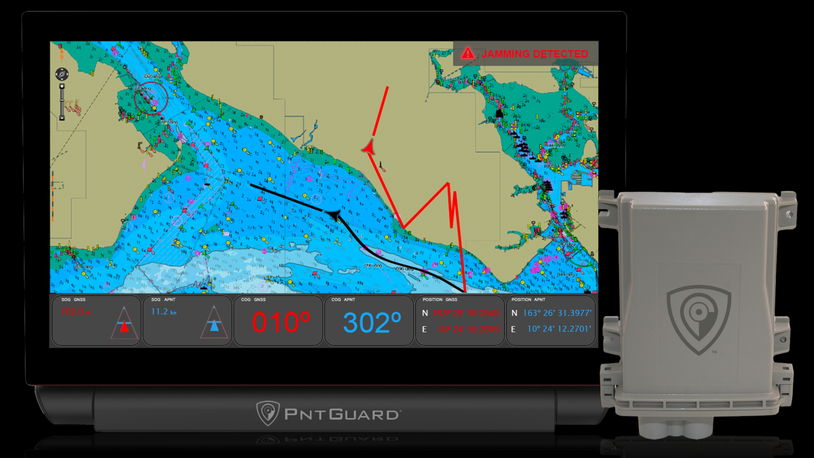

Maritime Navigation Innovation Webinar Week

© 2024 Riviera Maritime Media Ltd.