Business Sectors

Events

Ship Recycling Webinar Week

Contents

Righting the Ship: Preventing Torsional Vibration Issues in Modern Marine Propulsion Systems

Left unchecked, torsional vibration can lead to expensive repairs and lengthy downtime. That’s why marine operators look to Regal Rexnord, a global leader in understanding torsional vibration, as an integral part of their engineering efforts.

By specifying a Stromag 2-in-1 engine flywheel clutch/coupling, CENTA torsional couplings, and CENTA/Jaure intermediate drive shaft solutions – naval architects and shipyards building hybrid drives can ensure their designs are built to withstand torsional vibration from the most complex operating conditions.

What is Torsional Vibration?

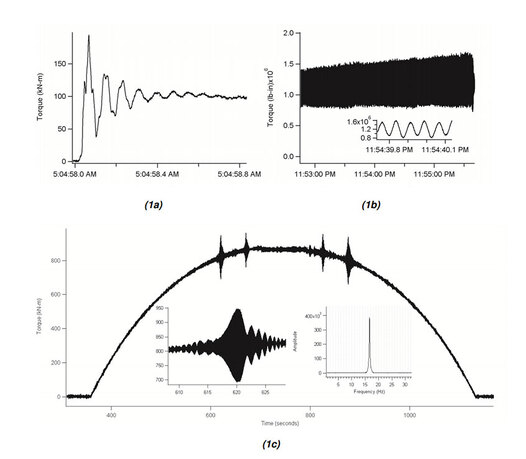

An engineer will tell you this: torsional vibration is the positive/negative angular displacement of a rotating shaft in a drivetrain, which is superimposed on the steady-state rotation of the system.

In layman’s terms, torsional vibration is the “twisting” movement of the rotating shafts that connect the various pieces of equipment in a drivetrain.

This form of vibration can be induced by the driving equipment, the driven equipment, or simply be the result of how the various inertias (rotating masses) and spring stiffness are distributed throughout the drivetrain. Internal combustion cylinder forces and variable frequency drives on motors also contribute heavily to the phenomenon.

How Does Torsional Vibration Happen in a Marine Setting?

Historically, oars, sails, steam, and low-speed diesel engines have powered the world’s ships. Early engines and marine transmissions were extremely heavy, low speed systems – so the influences for torsional activity were minimal.

As engines moved to modern medium and high-speed diesels – and as marine transmissions became lighter and lighter – propulsion systems became more susceptible to torsional vibration.

Recent efforts to cut down on carbon emissions make torsional vibration concerns even more prevalent.

The European Union and the United States have adopted strict emissions standards for propulsion engines and vessels in general. As the industry transitions to greener alternatives, owners and operators are looking to solutions with alternative fuel sources as well as alternative propulsion system design.

Regal Rexnord Coupling Engineers Solve Torsional Vibration Challenges

High-pressure fuel delivery and changing cylinder combustion pressures of alternate fuels greatly influence the torsional activity of an internal combustion engine. Hybrid drives utilizing alternative drive components – think, a power take off/power take in – increase the torsional activity as well. Even the most basic systems using variable speed electric motors driving propellers are susceptible to torsional vibration influences.

So, what’s the go-to solution for controlling torsional response?

Flexible couplings.

At the end of the day, the coupling is the “spring” that keeps everything else in check. By selecting the right coupling, a system designer can tune the system to avoid harmful resonance speeds, protecting the rest of the vital drive components.

The CENTAX-SEC and CENTAFLEX-A torsional couplings from CENTA offer torque transmission and misalignment compensation, while the Stromag 2-in-1 clutch+coupling solution offers seamless switching between diesel and electric power options.

Additionally, the Regal Rexnord Marine Solutions team can help with Torsional Vibration Analysis (TVA) – a vital tool for detecting adverse conditions in drivetrain components. A proper TVA will study the complete marine propulsion system. The TVA will consider the connected equipment and its operating conditions and predict stress levels and heat loads on components in the drivetrain.

As a team, Regal Rexnord engineers combine their many decades of experience in looking at each unique propulsion system. Understanding the properties of each component along with the operating conditions of the system allows them to present a well calculated system, free of harmful torsional resonance, and ready for many years trouble free operation – be it a traditional, alternative fuel, or hybrid system.

|

Robert “Bob” Lennon has been in the power transmission industry for 40 years, spending most of his career working in sales management, coupling engineering and applications for CENTA. A well-known industry expert, Bob appeared in the Feb. 2024 episode of the “Tech in Check” podcast, which was recorded at Workboat Show 2023. |

Related to this Story

Events

Ship Recycling Webinar Week

International Bulk Shipping Conference 2025

Tankers 2030 Conference

Maritime Navigation Innovation Webinar Week

© 2024 Riviera Maritime Media Ltd.