Business Sectors

Events

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

Contents

Register to read more articles.

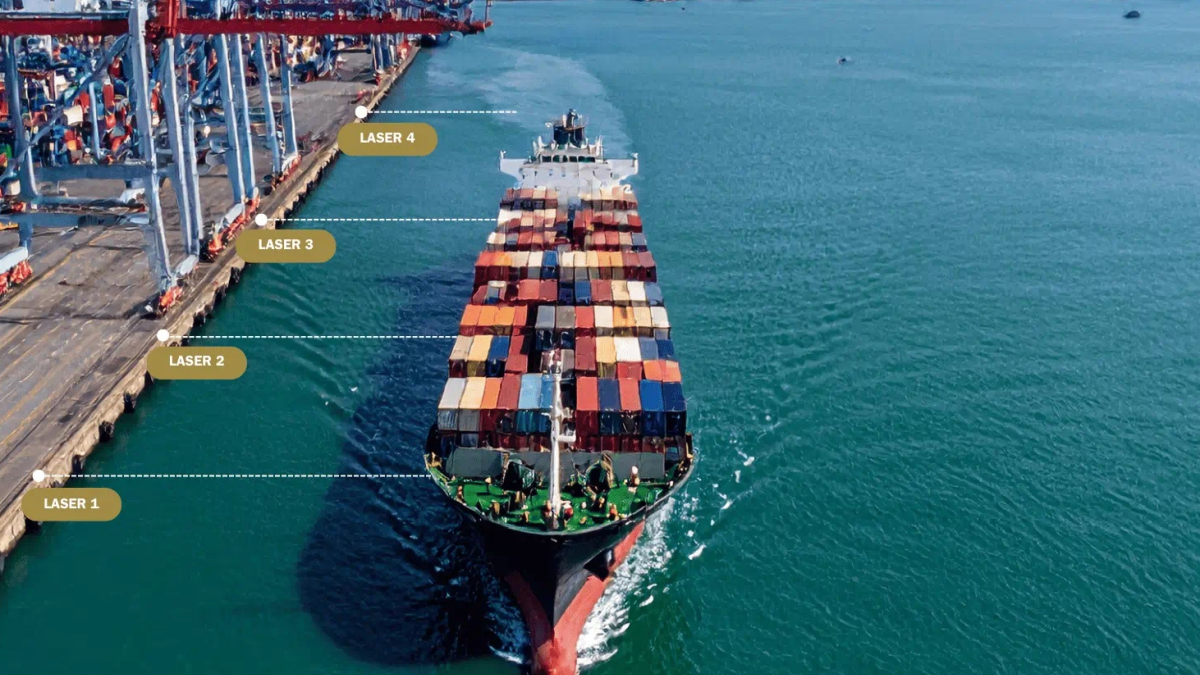

Ports deploy digitalisation for safer ship berthing

Ship docking can be optimised using a digitalisation system its developer said could transform traditional berthing operations

A new digital system has been deployed to provide port operators with comprehensive, objective data for smarter docking of ships at terminals to overcome operational challenges.

A container terminal in Australia and an oil terminal in the US have implemented this system to improve safety and cut costs.

Trelleborg Marine and Infrastructure has introduced its SmartDAS system as a smart aid to dock ships which uses data and continuous monitoring to safely and efficiently berth vessels at terminals.Data from various sources is analysed to support precise and simultaneous ship docking, enabling port operators to improve safety protocols, operational efficiency, infrastructure optimisation and environmental performance.

It incorporates information from the automatic identification system (AIS) and continuously monitors ship positions and other metrics, supporting ports to reduce energy consumption and design future terminal layouts.

"Modern port operations require intelligent solutions that provide actionable insights for both immediate operational decisions and long-term strategic planning," said Trelleborg Marine & Infrastructure business unit president, Richard Hepworth.

"SmartDAS delivers comprehensive data that empowers operators to make informed decisions across all aspects of berthing operations."

SmartDAS detects approaching vessels up to 200 m away and captures metrics including vessel distance, velocity and longitudinal angle. It integrates with AIS information to automatically match vessel identification with berthing information.

“Infrastructure damage prevention represents one of the key benefits of the monitoring capabilities,” said Trelleborg.

Trelleborg provided an example, implementing SmartDAS at a container terminal in Australia that experienced repeated unreported infrastructure damage. The terminal operator was able to identify patterns and establish accountability, enabling preventative measures and eliminating costly emergency repairs to infrastructure.

In another example, an operator of an oil terminal in California, USA used SmartDAS to streamline the configuration of infrastructure to minimise installation costs while maintaining full functionality of its assets.

Under SmartDAS, data is stored securely in a cloud-based facility enabling remote access to information. This product can integrate meteorological and oceanic data from sensors enabling correlation of environmental conditions with berthing performance, to help port and terminal operators to optimise operations based on actual conditions.

Operators can use this information “to analyse patterns, optimise procedures and make strategic decisions based on actual operational performance rather than assumptions,” said Trelleborg.

This digital “technology enhances safety through configurable alarms that warn operators when approach parameters exceed safe thresholds.”

“The system’s autonomous monitoring capability reduces human oversight requirements while providing continuous protection for vessels and infrastructure,” said Trelleborg.

“Operational efficiency improvements result from the system’s ability to generate comprehensive reports, replay historical berthing sessions, and identify optimisation opportunities.”

Data from SmartDAS can support port infrastructure decisions, enable optimised quayside fender design and lower emergency repairs through preventative maintenance practices. Mobile LED display boards can also be supplied to provide real-time feedback to approaching vessels.

SmartDAS has been incorporated into Trelleborg’s SmartPort technology platform that connects disparate, data-driven assets across the port environment, “giving stakeholders a holistic view of operations.”

’s nextVessel Optimisation Webinar Weekfocus on AI-driven vessel optimisation, practical decarbonisation strategies, and the integration of digital twinUse this link for more information and to register

Related to this Story

Events

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

© 2024 Riviera Maritime Media Ltd.