Business Sectors

Events

Contents

Register to read more articles.

AI, digital twins help design cyber-secure, green SOVs

Artificial intelligence (AI) is helping to design the next generation of vessels servicing offshore windfarms with the latest technology for sustainable operations and low emissions

While advances in digitalisation are enabling vessel owners to operate offshore maintenance vessels more efficiently, artificial intelligence (AI) and digital twins are helping naval architects reduce fuel consumption, emissions and noise on future vessels.

Improvements in class unified requirements and system integration is helping shipyards to construct vessels with high levels of cyber resilience, particularly in the onboard operational technology (OT).

This comes as vessels are becoming increasingly connected to the internet and cyber criminals and state-backed attackers are becoming more advanced in their constant attacks.

An expert panel explained how the next series of service operations vessels (SOVs) will have high levels of cyber security and powertrains involving green fuels, during Riviera’s How AI, digitalisation and cybersecurity enhance capability and reduce emissions webinar.

Vard Group head of maritime cyber resilience Gaute Hjellbakk Pettersen explained how the latest newbuild SOVs will be completed to align with the unified requirement (UR) E26 of the International Association of Class Societies (IACS) regarding cyber resilience in ships.

Integrated bridge, automation and power management systems on these vessels will also comply with IACS development UR E27 for cyber secure components on vessels.

“IACS unified requirements are a good starting point, and a major lift for the industry,” said Mr Pettersen. For ship design and construction operations, these URs bring “safety and security, while putting in cyber controls that make sense,” he continues, “setting out structures to work with integrators and build a culture of cyber security.”

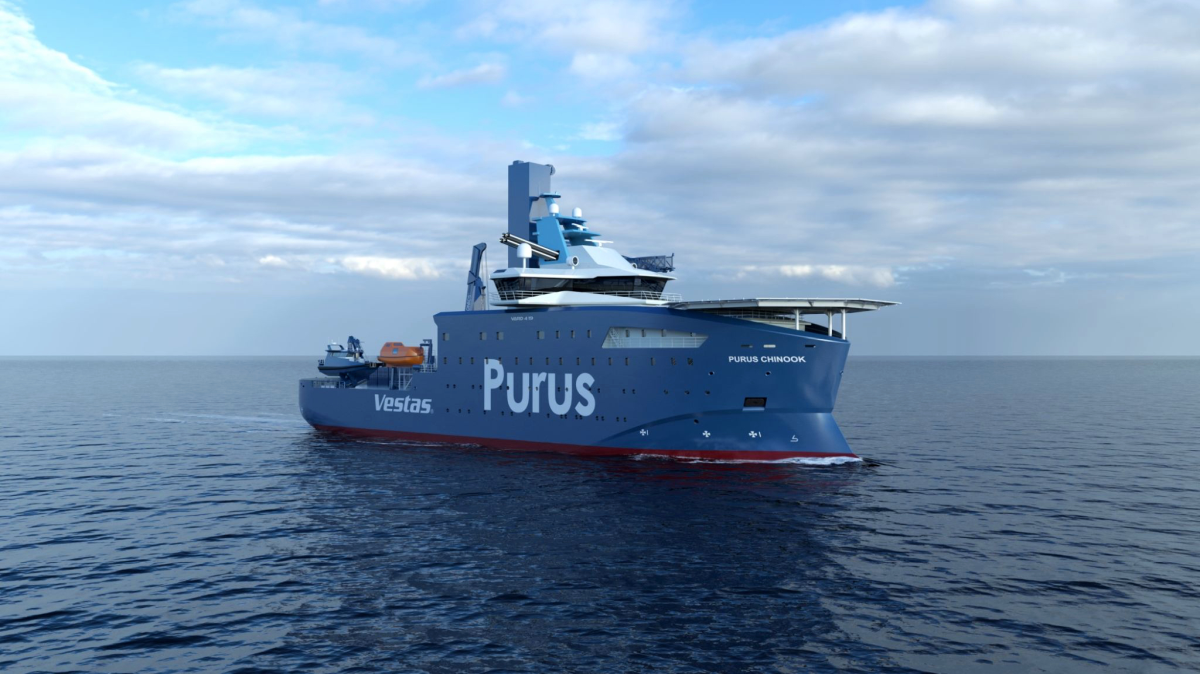

Fincantieri Group subsidiary Vard has built in Norway SOVs that are aligned with these IACS URs and with class cyber-resilience notations for various owners. For example, North Star’s Grampian Kestrel and Purus’ newbuild Purus Chinook both have class notations demonstrating they comply with new mandatory cyber-security requirements.

A significant portion of the electronic systems on board these SOVs were delivered from Vard Electro’s SeaQ portfolio.

Vard Electro took full responsibility for the cyber integration, testing across all onboard systems, demonstrating that their cyber resilience is in line with the latest regulatory and class standards.

“Critical systems on SOVs are cyber secure” and can be maintained as such through regular management and cybersecurity updates, Mr Pettersen said.

He says cyber security is essential for the future of offshore support vessels as it enables semi-autonomous operations and remote control of ships.

“Technology is here and ready, but we need cyber security and we need to trust in data and its integrity for reliable operations,” said Mr Pettersen. “With cyber resilience, the possibilities are endless.”

Longitude Engineering senior marine engineer Amy Potter described how the company used AI, digital modelling and digital twins to design optimised and low-emissions powertrains for SOVs to use green fuels and the latest energy storage, engines and fuel cells.

“We used an AI optimisation algorithm to select the optimal powertrain for capital or operational expenditure, carbon intensity or emissions reduction,” said Ms Potter.

“We provided information to the algorithm on weight, space and max power that the vessel needed to provide,” she said.

“It was almost like a retrofit solution as we were using an existing design, and then looking at what could be fitted in and what would need to be removed.”

Training the AI requires a large amount of input from naval architects, academia, vessel owners and equipment vendors.

“We used guidance from an OEM on components of a powertrain, including methanol reformers, engines and fuel cells,” said Ms Potter. These datasets and models were incorporated into the algorithm.

But, there are many other feasibility factors to consider for future studies, including fuel availability, bunkering, crew requirements, training, operational impacts and classification issues.

“We need to consider technology readiness, fuel availability now and in the long term, stability of the vessel, reliability of equipment and modifications of systems in the future.” These could include batteries and fuel cells and that many need replacement engines or engine overhauls over the lifetime of a vessel’s operations.

SOV powertrain study

In the UK, Longitude was the lead partner in a project that assessed the potential of AI in the design of a ship’s powertrains, in a consortium that comprised of the University of Birmingham, DNV, Steamology and Chartwell Marine, with support from North Star Shipping.

Longitude used an existing SOV design and digital twins of in-service vessels to gather operational data. It assisted the University of Birmingham in training the AI tool by applying its knowledge in vessel design and alternative fuels to set parameters such as weight, space, regulatory constraints.

The outputs of the AI tool were used to develop preliminary designs of four SOV variants. The first had methanol fuel storage and a methanol to hydrogen reformer, a hydrogen fuel cell and batteries. The second had liquid hydrogen storage, hydrogen fuel cell and batteries; the third diesel and hydrogen fuel storage, with diesel internal combustion engines and hydrogen turbine plus batteries; and the fourth methanol fuel storage with methanol internal combustion engines and batteries.

Ms Potter said this study identified green methanol as the key fuel and energy storage as an important technology for the medium term, but there was potential for the other fuels and technologies for the long term.

Webinar poll results:

Attendees were asked to vote on a series of poll questions during the webinar, and here is a summary of the results.

Based on your operational experience, what is the primary barrier preventing immediate adoption of alternative fuel powertrains in your SOV fleet?

Capital cost and financing challenges — 39%

Fuel infrastructure and supply chain immaturity — 38%

Regulatory uncertainty and classification requirements — 15%

Technical risk and reliability concerns — 8%

If forced to choose one metric to optimise for in your next SOV powertrain design, which would drive the greatest long-term value?

Minimising total cost of ownership over 20 years — 23%

Achieving maximum emissions reduction — 0%

Ensuring the highest operational flexibility and redundancy — 56%

Meeting the most stringent future regulatory requirements — 21%

Considering the AI optimisation results presented, when do you realistically expect your organisation to deploy methanol-fuelled SOVs in commercial operations?

Within 2-3 years for new builds — 23%

4-6 years following infrastructure development — 33%

7-10 years after regulatory framework maturation — 29%

Beyond 10 years due to economic and technical barriers — 15%

In your assessment, which represents the greatest cybersecurity threat to modern vessel operations?

Ransomware attacks targeting business systems and data — 63%

Nation-state actors targeting navigation and propulsion systems — 25%

Supply chain compromises in critical hardware components — 12%

Insider threats from crew members or contractors with system access — 0%

On the panel of Riviera’s How AI, digitalisation and cybersecurity enhance capability and reduce emissions webinar were: Longitude Engineering senior marine engineer Amy Potter and Vard Group head of maritime cyber resilience Gaute Hjellbakk Pettersen.

Riviera’s Offshore Support Journal Conference, Americas will be held in Rio de Janeiro, 7-8 October 2025. Click here to register your interest in this industry-leading event.

Related to this Story

Events

Maritime Regulations Webinar Week

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

© 2024 Riviera Maritime Media Ltd.