Business Sectors

Events

Contents

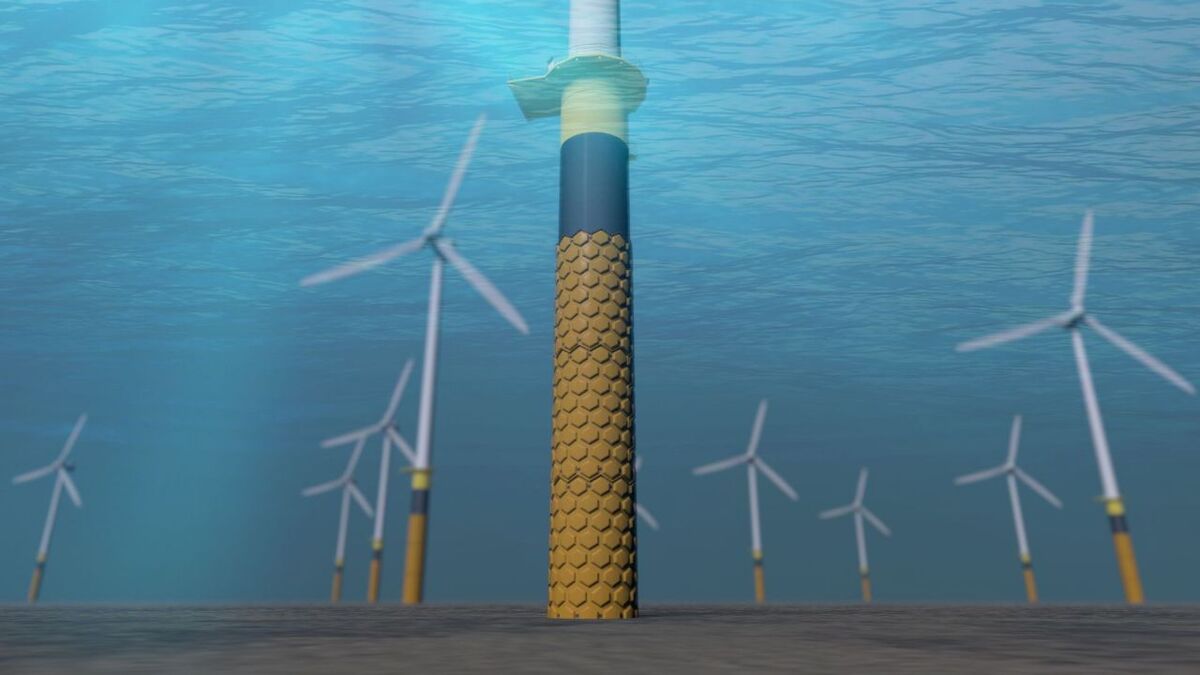

Balmoral unveils innovative scour protection system for offshore wind turbines

Balmoral has unveiled a novel patented product for the offshore wind market the aim of which is to reduce scour around bottom-fixed wind turbines

Scour leads to seabed erosion, a reduction in foundation strength, stiffness and can ultimately lead to turbine foundation instability and inter array cable damage, resulting in expensive cable failure. To mitigate this phenomenon, scour protection is used to defend the seabed around a monopile structure.

Scour protection typically involves the installation of a layer of material around the base of the monopile to prevent sediment erosion. This can be made of various materials including rock, concrete or a specially designed geotextile fabric. The layer is placed on the seabed around the monopile to dissipate the energy of the fluid flow and reduce erosion rates.

These measures need to be carefully monitored to avoid damage to the turbine, seabed and any associated cabling. The cost involved in this process, along with the carbon footprint implicated with extra quarrying and vessel time for installation, is significant.

To address these issues, Balmoral has developed HexDefence, a scour protection system that integrates seabed protection and flow reduction to minimise offshore operational costs and potential cable failure.

The HexDefence structure eliminates the requirement to dump rock, instead providing a non-invasive approach to protecting the monopile and the immediate surrounding area.

Balmoral said the construction of HexDefence, using lightweight composites and a streamlined installation process, make it easy to install without the need for dedicated vessels, resulting in an improved carbon footprint for all operations. In addition, HexDefence can be used with coatings and does not require special equipment for end-of-life recovery.

Following positive discussions with leading windfarm developers and industry bodies, Balmoral has been encouraged to bring the product to market as soon as possible.

Balmoral engineering and projects director Fraser Milne said, “We believe HexDefence represents a significant step forward for scour protection, offering highly cost-effective performance enhancement across installation, management and maintenance.

“The interlocking panels are generally 10 m long, custom-sized to fit varying monopile diameters and feature integrated lifting and access points.

“In simple terms, the installation process involves sinking the foundation, sleeving it with HexDefence, fitting the transition piece and assembling the pylon and blades. The system is also suitable for retrofitting to existing monopile structures.”

Preliminary work on HexDefence was based on existing VIV suppression products used widely by the oil and gas sector. Research considered a scaled variant to investigate scour evaluation on downstream flow and the effect of accelerated currents around the monopile. Final prototype testing was completed at a national hydrodynamic laboratory.

“We believe the system can save windfarm developers around 70% in installation costs when compared with traditional rock dumping methods”, concluded Mr Milne.

Sign up for Riviera’s series of technical and operational webinars and conferences in 2023:

- Register to attend by visiting our events page.

- Watch recordings from all of our webinars in the webinar library.

Related to this Story

Events

Maritime Regulations Webinar Week

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

© 2024 Riviera Maritime Media Ltd.