Business Sectors

Events

Offshore Wind Webinar Week

Contents

Register to read more articles.

Hybrid transmission unveiled for harbour vessels

Rising demand for electric propulsion in port and coastal vessels has driven the development of integrated drives, transmission and PTI gearboxes

Manufacturers and integrators have revealed combined solutions for generating and transmitting power to thrusters and propellers on vessels operating in ports and along coastlines.

Tightening emissions regulations and rising pressure from port authorities have increased the demand for electric-driven harbour vessels and workboats, generating requirements for innovative green propulsion, some of which was presented during the SMM exhibition in Hamburg, Germany, in September 2024.

Geislinger has teamed up with AVL to develop E-Drive, an integrated electric propulsion powertrain for tugboats, workboats, fast ferries, crew and pilot transfer ships and research vessels.

This lightweight propulsion system combines AVL’s latest electric motor with Geislinger’s powertrain, including dampers, shaft line and couplings.

Geislinger director of innovation Philipp Stuhlpfarrer introduced the E-Drive during a presentation at SMM. He says the companies worked together to optimise mechanical interfaces and reduce the weight and space required for integrated electric propulsion, with an electric direct-drive motor to operate without a gearbox.

E-Drive can include Geislinger’s acoustically optimised Silenco coupling to minimise noise and vibration, which is becoming increasingly important for vessels operating where authorities seek to protect marine life from shipping’s disruptions.

“AVL would supply the electric motor and inverter with high output torque and low vibrations and the couplings, shaft, flanges and torsion monitoring system is from Geislinger," Mr Stuhlpfarrer says. “From a technical perspective, we have designed and optimised this powertrain to be a silent propulsion system.”

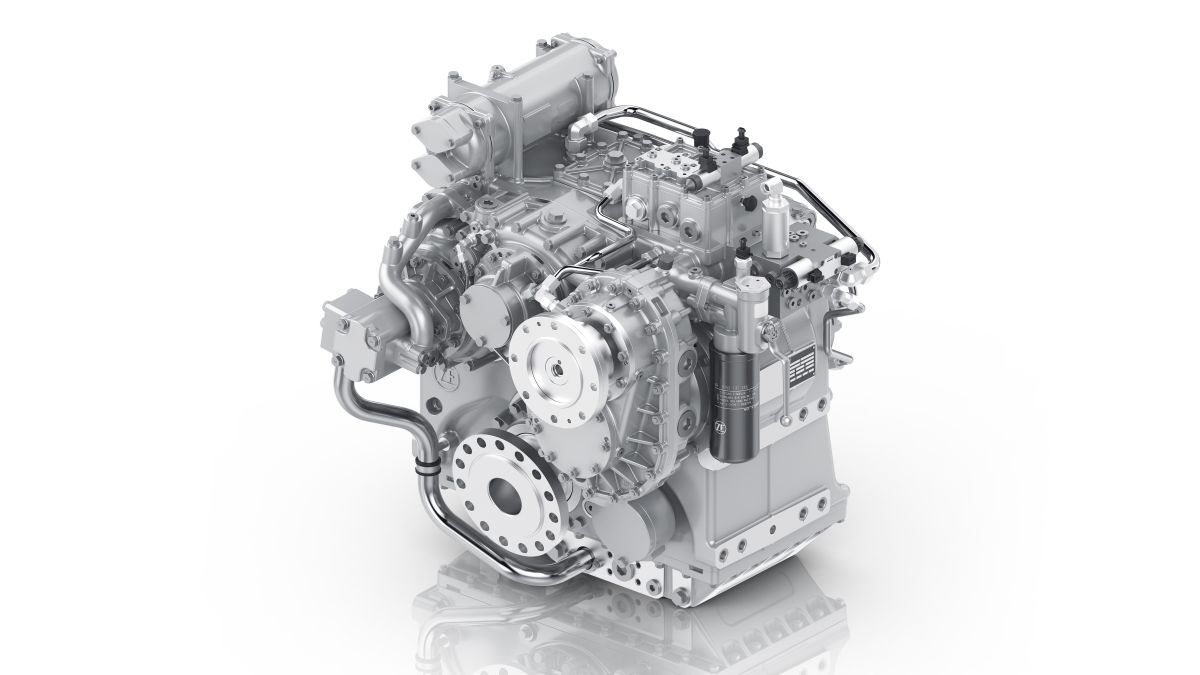

Friedrichshafen, Germany-headquartered ZF has revealed its new hybrid transmission for fast vessels, harbour craft, patrol boats and ferries. The ZF 3000 transmission series has been extended with the ZF 3200 A/V PTI (power take-in) for a power range from 1,295 kW to 1,940 kW.

ZF says this hybrid down-angle transmission is compact, and light enough to be installed on fast craft with limited installation space due to its aluminium housing.

Its gearing design means an additional electric motor unit can be connected via its own drive shaft without reducing the permissible power of the main drive for a hybrid propulsion configuration.

ZF 3200 A/V has a maximum output of up to 1,940 kW and a maximum torque of 7,560 Nm, while the PTI can be coupled with electric motors up to a maximum output of 500 kW.

ZF previously only offered hybrid transmissions with a larger ratio in this power range – suitable for workboats, but not ideal for other applications.

This new transmission covers the ratio range from 1.351 to 3.444. “This makes it the optimal solution for applications in fast craft with limited installation space,” says ZF head of commercial sales for fast craft transmissions, Wolfram Frei.

Demand for hybrid propulsion solutions for fast vessels in harbours and coastal areas has risen to reduce pollution and CO2 emissions, leading to transmission developments which enable electric motors and small batteries to be used.

At the PTI, the ratio can be selected in a range from 1.892 to 4.240. “In addition, we can implement different or additional ratios at the power-take-in,” adds Mr Frei. This enables the ratios to be adjusted to suit the operational profile, for example, during short-term boost modes or manoeuvring.

Gearbox acquisition

New York, US, NASDAQ-listed Twin Disc has acquired Finnish gearbox and power transmission manufacturer Katsa Oy, widening its offerings in the growing hybrid and electrification market.

Twin Disc completed the US$23M acquisition in Q3 2024, adding complementary products and expanding its footprint in the European market.

For the fiscal year ended 30 September 2023, Katsa reported about US$36M in revenue.

Twin Disc president and chief executive John H Batten says the acquisition will enable the company to build on Katsa’s longstanding relationships with European original equipment manufacturers, and growth opportunities in electric and hybrid applications.

One of Katsa’s newest products, for example, is a hybrid power take-off (PTO) gearbox concept. It is also developing new winch gears and winch electric powerpacks using permanent magnet motor technology.

Hydrogen fuel-cell technology

A joint venture between Japanese group Honda and UK’s Hypermotive is preparing to test marine applications of hydrogen fuel-cell technology in 2025. The X-M1 modular hydrogen fuel-cell power unit is designed to supply clean energy for vessel applications including yachts and workboats.

The X-M1 is the first proof of concept (PoC) for Honda’s latest hydrogen fuel-cell system in Europe. For vessel retrofits, it can be integrated with existing ship components, and its modular design enables greater flexibility for transiting to hydrogen use, according to the UK developer.

Powered by Honda, X-M1 uses Hypermotive’s System-X technology, which combines hardware and software products to enable optimised hydrogen power systems using fuel cells and compressed gas storage, and connect them to applications and the cloud.

Honda Motor Europe deputy general manager, Europe business planning and development, Ingo Nyhues says, “There is a great opportunity with the maritime industry to demonstrate the performance and efficiency of a hydrogen solution like X-M1, which is a significant step towards achieving carbon neutrality in this sector.”

The X-M1 will be brought to market through a joint engineering process with Honda, with PoC trials planned for 2025 to test the system meets the highest standards of reliability, safety and performance before full-scale deployment. The system will be installed on a vessel, with a customised assessment to enable cross-functionality with existing systems and engineering.

Germany-based, family run Höpen group will focus on developing maritime applications for emissions-free technologies, including batteries and hydrogen fuel cells, following its departure from its venture with Becker Marine Systems in September 2024.

Winsen-headquartered Höpen says it will strengthen technologies developed through its subsidiaries eCap Marine and Lehmann Marine, while Becker will continue concentrating on ship propulsion, manoeuvring solutions and hydrodynamic performance packages.

Lehmann Marine has provided its Cube and Cobra energy storage system to several workboats and harbour vessels, dredgers and offshore support vessels.

This includes workboat Chicago, which supports vessels in the Port of Hamburg with a 423-kWh, water-cooled Cobra battery unit, and in Acta Marine’s offshore supply vessel Coastal Liberty, which operates in a vulnerable tidal zone in the North Sea.

The hydrogen power generator, H2PowerPac from eCap Marine, provides emissions-free propulsion energy during operations in the Wadden Sea National Park and incorporates a 280-kWh Cobra unit. In September, Lehmann Marine gained type-approval from class societies DNV and RINA for its modular lithium-ion Cube battery system.

Riviera’s TUGTECHNOLOGY ‘25 will be held in Antwerp, 22-23 May 2025. Click here for more information on this industry-leading event.

Related to this Story

Events

Offshore Wind Webinar Week

Maritime Decarbonisation, Europe: Conference, Awards & Exhibition 2025

Offshore Support Journal Conference, Americas 2025

© 2024 Riviera Maritime Media Ltd.