Business Sectors

Contents

Register to read more articles.

New technologies drive STS safety

Victrol’s Joachim De Ruiter discusses how advanced monitoring systems, protective measures and standardisation are improving safety in ship-to-ship operations and LNG bunkering

Ship-to-ship (STS) transfer operations are essential for maritime logistics, allowing vessels to redistribute cargo efficiently. However, these operations carry inherent safety risks, particularly with the rise of new fuels. As the shipping industry continues to evolve, safety technologies play an increasingly critical role in mitigating these risks.

Companies providing STS services have evolved, too. One such company is Victrol, a family owned operator founded in 1967, which has long been involved in advancing safety practices in hazardous liquid transport.

Speaking ahead of his presentation at the LNG Shipping & Terminals Conference, Victrol QHSE manager Joachim De Ruiter stressed the company’s focus on safety innovations, "Victrol has always been at the forefront of technical and safety developments, contributing both to the technological evolution of shipping and to the practical knowledge that influences regulatory bodies."

With a decade of experience as a tanker barge captain and extensive work as a cargo surveyor and OCIMF inspector, Mr De Ruiter brings a deep understanding of the safety challenges in STS operations.

At Victrol, he is responsible for overseeing legal compliance and safety procedures, particularly in the growing area of LNG bunkering.

"Together with Peter Maes, our design lead for LNG vessels, we have developed safety procedures for the safe delivery of LNG to a variety of receiving parties," Mr De Ruiter explained.

STS transfers pose unique safety risks, including adverse weather, equipment failures, and the potential for spills.

As Mr De Ruiter noted, "Bunkering comes with additional risk due to less familiarity or experience of the crew of the receiving vessel with the specific risks of the cargo."

To address specific safety concerns, Victrol has implemented innovative solutions such as protective tables above tank domes.

This measure aims to prevent damage from falling containers during transfers. "The tank domes are the most critical part of the cargo system because they cannot be isolated if damaged," Mr De Ruiter explained.

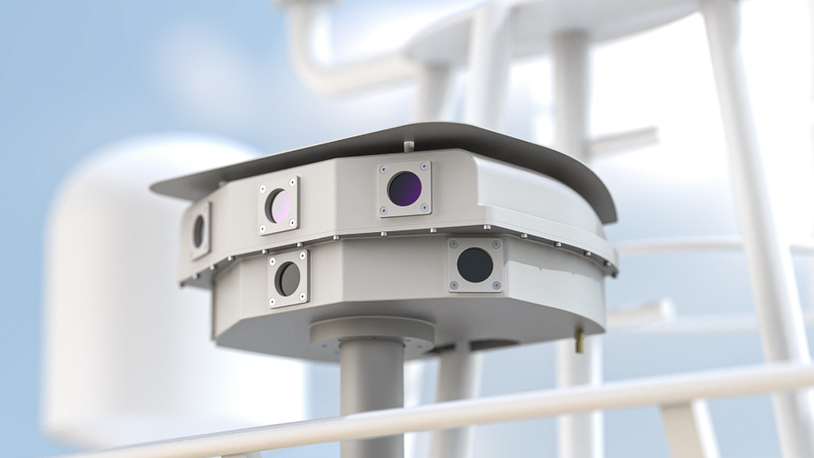

Technological advancements are at the forefront of improving STS safety. Real-time monitoring systems now allow operators to respond quickly to changes in cargo and environmental conditions, though Mr De Ruiter stresses that user-friendly designs are essential for their effectiveness. "If the user interface of these systems is well integrated and easy to use, it has its benefits," he said.

One of Victrol’s key innovations is the development of its bunker boom, developed in conjunction with boom producer van Wijk and cryogenic product transfer equipment specialist Kanon for barge LNG London. This system has been successfully used in more than 1,000 LNG bunkering operations.

Standardisation is another crucial aspect of improving STS safety. Mr De Ruiter stressed the importance of designing simple, reliable systems that minimise the risk of human error.

In this regard, ISO 21593 standardisation on LNG transfer has been a huge gain in the operational benefits of using a Dry Connect Dry Disconnect coupling.

"If an operator must deal with a lot of fragile components and complicated systems, the chance of malfunction increases, causing people to cut corners," he explained.

Looking to the future, new technologies such as vacuum or magnetic mooring systems to keep both vessels moored alongside could further enhance safety by reducing manual interventions during transfers. As new fuels such as methanol and ammonia emerge, the industry will need to adapt its safety regulations accordingly.

Mr De Ruiter expects the regulatory frameworks established for LNG will serve as a foundation for future fuels, "For LNG, the rules and regulations are set, but there will be new developments when other fuels arise."

Learn more about STS and safe LNG bunkering operation at the LNG Shipping & Terminals conference.

Related to this Story

Events

Maritime & Offshore Community Golf Day 2025

Offshore Wind Webinar Week

Maritime Decarbonisation, Europe: Conference, Awards & Exhibition 2025

Offshore Support Journal Conference, Americas 2025

© 2024 Riviera Maritime Media Ltd.