Business Sectors

Contents

Vibration installation aims to shake up offshore industry

In April, RWE Innogy, Dong Energy, EnBW, E.ON and Vattenfall announced that work was underway on a one-year onshore test to validate the vibratory driving of large monopiles for use offshore – with support from The Carbon Trust offshore wind accelerator (OWA) and the offshore wind industry.

The aim of the project is to reduce the costs, risk and noise emissions associated with offshore monopile installation in future European offshore wind projects. The results of the first tests are due for release at the end of 2014. Recent German regulations limiting underwater noise emission to 160db at 750m – and other similar regulations – are making foundation contractors aware of the importance of protecting the marine mammals around the job site. A key project objective is to demonstrate that the lateral load capacity of vibrated and hammered piles in sand “is to be regarded as equivalent”. The initiative also aims to prove that the full depth vibro-driving of monopiles in comparison to hammered piles has lower noise levels, causes less fatigue and stress to the monopiles, is faster and more cost-effective. A final objective is to demonstrate that the technique can simplify the installation of large monopiles, mainly because fewer tools would be necessary for the construction of offshore wind turbines.

As part of the initiative, the partners will carry out a one-year onshore demonstration project near Cuxhaven on the German North Sea coast to validate the vibratory driving of wind turbine monopile foundations, in comparison with and as an evolution of current impact driving of such piles. According to RWE, the potential benefit is “faster and more environmentally benign monopile installation in offshore windfarm projects”.

“The aim of the Vibro project is to verify the effect of vibratory driving on soil conditions, in comparison to impact driving,” said Tobias Griesshaber, project manager for the Vibro project at RWE. “It will enable the application of full-depth vibratory driven piles.”

“Traditionally, piles are installed by heavy impact hammers,” said Jan Matthiesen, offshore renewable technology acceleration manager at The Carbon Trust. “This technique creates high sound pressure levels, which need to be mitigated to protect the marine environment. The vibration of offshore piles is an alternative installation technique that will reduce noise emissions at the source. Standard design procedures will apply for fully vibratory driven piles so that, for the first time, the participants can vibrate piles to full installation depth.”

In collaboration with the certification and regulatory bodies, Mr Griesshaber says that three monopiles will be installed via vibration by the project’s installation partner Bilfinger Construction and benchmarked to another set of three monopiles driven with conventional impact hammering, in order to compare their performance through a variety of tests.

RWE says that the results will have an immediate impact on current projects under development in Europe, and will be used to improve the ongoing windfarm design process for the planned Nordsee One offshore windfarm developed by RWE, located about 40 kilometres north of the North Sea island of Juist.

Mr Matthiesen explained that one challenge facing the project team was the choice of location to test – as he points out, this has been carefully examined with several potential locations investigated. “The primary boundary condition is appropriate soil characteristics – high groundwater level and predominantly dense and very dense sandy soils comparable to North Sea offshore locations,” he told OWJ. “A sandpit near Cuxhaven on the German North Sea coast simulates these offshore conditions ideally, and a construction permit is being prepared.” Eventually, he believes, full-depth vibratory pile driving could cut pile driving times by half and reduce vessel rental costs significantly. In his view, this could also have an impact on costs. Another important potential advantage of vibratory driving is that it can be expensive finding a way to mitigate the noise caused when driving piles in the conventional way – with a pile-driving hammer.

How does it work?

Vibratory pile hammers contain a system of rotating eccentric weights, powered by hydraulic motors. The eccentric weights rotate in direction counter to one another to cancel out the horizontal vibrations, while only the vertical vibrations are transmitted into the pile. The vibratory hammers are directly clamped to the pile and therefore make the pile handling much more efficient, while saving time and costs. OWJ

Related to this Story

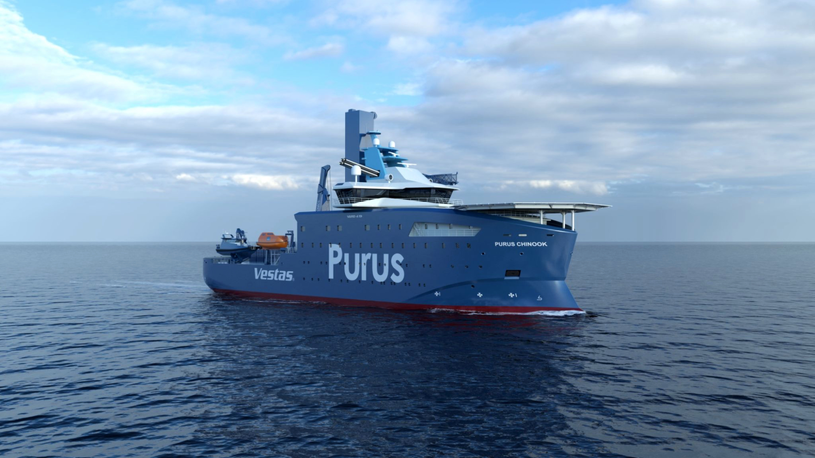

AI, digital twins help design cyber-secure, green SOVs

Events

Offshore Support Journal Conference, Americas 2025

LNG Shipping & Terminals Conference 2025

Vessel Optimisation Webinar Week

© 2024 Riviera Maritime Media Ltd.