Business Sectors

Contents

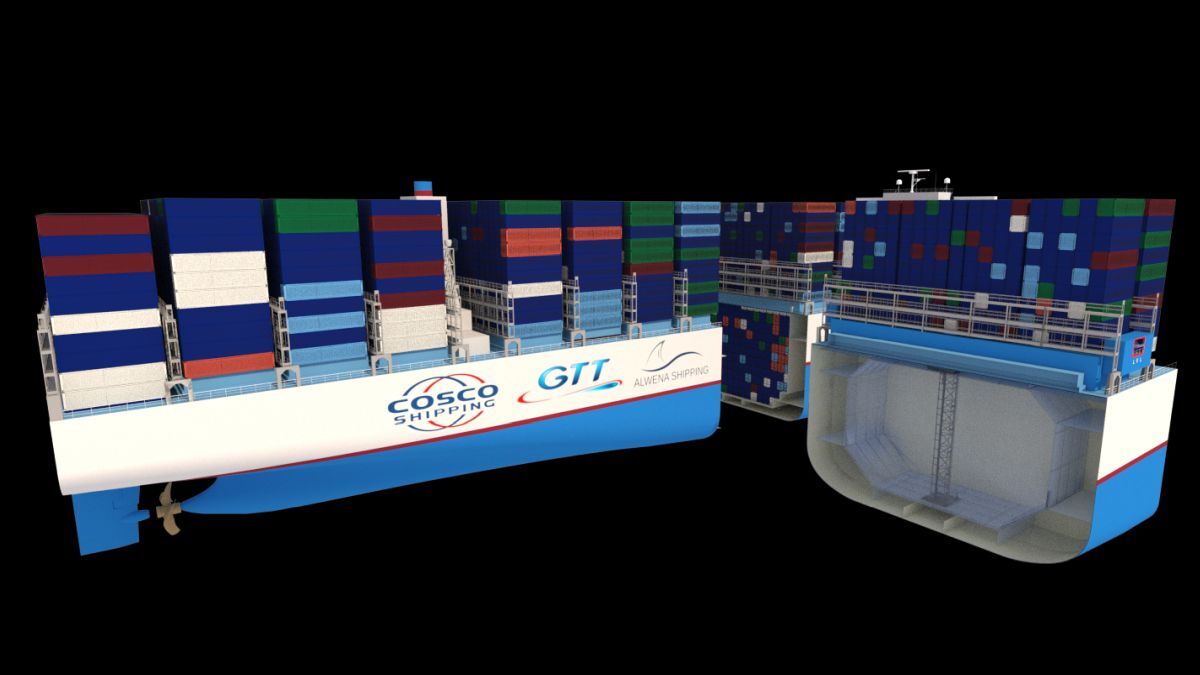

Container ships: LNG retrofit and jumboisation

Gaztransport & Technigaz (commercial division) business development manager Jean-Benoît Bensoussan discusses retrofitting and jumboising a 14,000-TEU container vessel

IMO has set new targets to reduce CO2 emissions from transport work: a decrease of 40% by 2030 and 70% by 2050, compared with 2008 levels, and for annual greenhouse gas emissions from international shipping, stipulates a reduction of 50% by 2050. Two associated IMO indices – EEXI and CII – have been established to provide shipowners with a benchmark to reduce levels and get on track to meet the objectives

Facing these new requirements, shipowners and maritime stakeholders have to take measures to make their existing fleet compliant with the regulations. An LNG retrofit offers a solution to this challenge.

LNG retrofits for container vessels are challenging, as they require smart, compact solutions for the LNG tank due to space constraints. This is where the use of GTT membrane technology is justified.

In this context, GTT has decided to build upon the first large-scale LNG retrofit of Hapag Lloyd Brussel Express (ex Sajir) and improve the business case by proposing a solution combining the LNG retrofit with a cargo capacity increase to reduce the payback time of the conversion.

A new section composed of the LNG tank, LNG fuel gas handling system (FGHS) and a cargo bay to load containers, is integrated towards the aft of the vessel. This lengthening operation is called jumboisation.

In January 2021, GTT, maritime advisory Alwena Shipping and Chinese repair shipyard COSCO Shipping Zhoushan decided to launch a joint development programme to study the technical and economic aspects of this retrofit operation.

As a result of this collaboration, the study received an approval in principle from the French classification society Bureau Veritas in January 2022.

Market analysis showed the targeted container family size was between 9,000 TEU and 14,000 TEU, less than 10 years old, with a second special survey due in the next few years. For the sake of the study, the focus was put on a 14,000-TEU container vessel.

LNG retrofit and jumboisation can extend the lifetime of the asset until 2045, as each operation acts on the numerator and denominator of the EEXI and CII formula, the tools put in place by IMO to monitor and control vessel CO2 emissions

Jumboisation consists of cutting the container vessel in two and inserting a new section in between. This new section is almost 30-m long and has the same breath as the ship

It comprises room for more than 1,100 TEU and an LNG tank of 12,200 m3. This LNG capacity allows this size of ship to make return voyage Asia-Europe.

The tank is equipped with GTT Mark III membrane technology, with a guaranteed BOR performance adapted to the lowest consumption level of the vessel.

The new block made of the LNG tank and the new container bay is built at the retrofit yard or at a GTT-qualified block manufacturer prior to the vessel’s arrival. It is equipped with the FGHS on top to reduce interfaces and retrofit duration.

The vessel arrives in the drydock at the shipyard, is cut in two, the fore part of the ship is floated out and the new section is floated in followed by the fore part. All three sections are aligned, the drydock is emptied and the three sections are welded back together.

The vessel will stay 42 days in the drydock, four months at the shipyard, and the whole project will take two years from early engineering to commissioning.

Based on market prices of Q1 2022, the cost of the operation is estimated at around US$41M, while the additional revenue generated by the cargo capacity increase will generate an additional revenue of US$6M. Also considered in the business case, is the loss during off-hire and the savings generated by switching from conventional fuel to LNG. The business case has been built considering average historical prices for fuel costs, freight and charter rates.

Overall, this study showed the initial investment of US$41M would pay back in less than seven years, very soon compared with extending the lifetime of the asset until 2045.

While the newbuilding market becomes saturated, LNG conversion is a proven and available solution that allows shipowners to meet IMO regulations and the jumboisation will offer an additional source of revenues contributing to improving the payback of the operation.

For more on this solution, please join Riviera Maritime Media’s The case for LNG retrofit and jumboisation of container vessels The case for LNG retrofit and jumboisation of container vessels (clickmeeting.com)

Related to this Story

Events

Maritime Decarbonisation, Europe: Conference, Awards & Exhibition 2025

Offshore Support Journal Conference, Americas 2025

LNG Shipping & Terminals Conference 2025

© 2024 Riviera Maritime Media Ltd.