Business Sectors

Events

Contents

Register to read more articles.

Virtual twins: the future for ship class, lifecycle management

Digital technologies are rapidly advancing with digital twins of vessels being used to improve design, engineering, classification, maintenance and operations

Virtual twin use is moving from pilot projects to operational use, with 3D models increasingly used for ship design, engineering and classification. With the models kept updated using high-quality data, digital twins can be used for predictive analytics, system maintenance, fuel efficiency and voyage optimisation.

An expert panel discussed the applications and future developments of this advanced digital technology during Riviera’s Digital Twin Integration: From Concept to Fleet-Wide Value webinar, which was held on 24 October 2025 during Riveria’s Vessel Optimisation Webinar Week.

On the panel were Indian Register of Shipping (IR Class) chief technology officer Rabindra Sah and Kongsberg Maritime vice president for special projects and product line manager for performance and fleet management, Anders Bryhni.

They detailed the latest deployments in digital twins, the integration challenges and how to unlock the full value of virtual twins across vessel lifecycles.

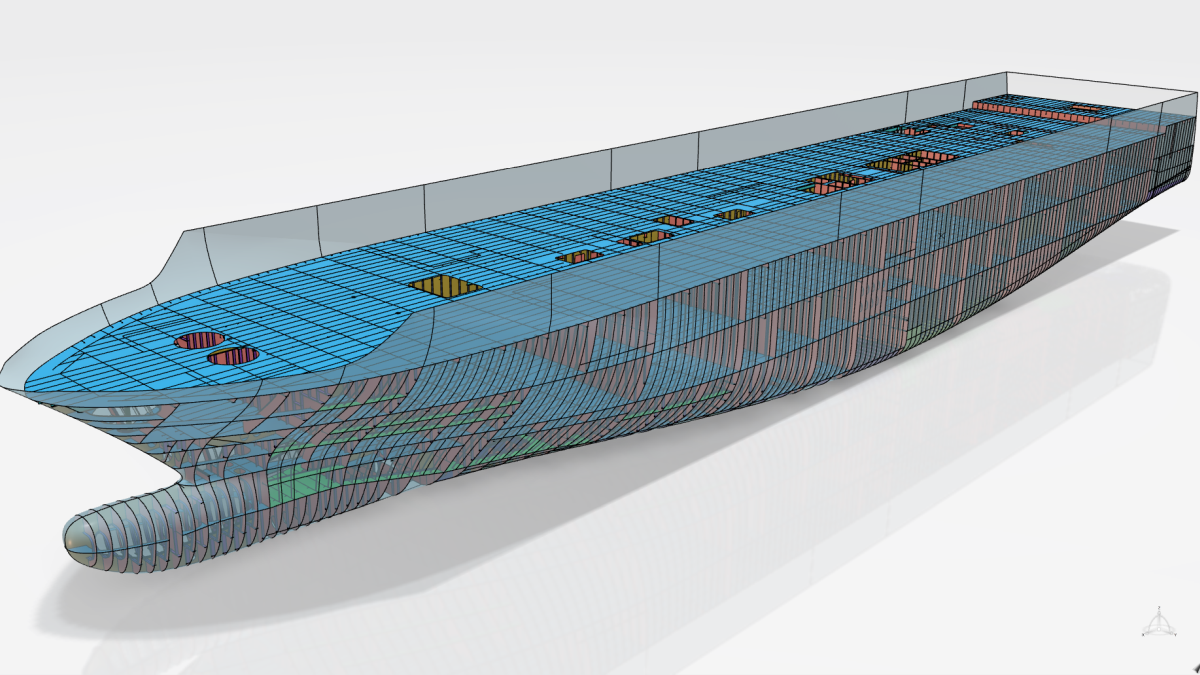

Mr Sah explained how IR Class is spearheading the use of virtual, or digital, twins when classifying ships and approving newbuilding designs at shipyards. It is using Dassault Systemes’ digital platform 3DExperience to create virtual twins of ships for lifecycle assessments and 3D classification.

Mr Sah said these 3D models can be a “single source of truth” that multiple stakeholders can use to collaborate in ship design, construction and lifecycle management.

“We have taken an initiative in digital transformation with virtual twins that include high-fidelity digital models of ships for design, operational history and lifecycle evolution, using real-world data for simulation and monitoring,” he said.

“Virtual twins will help in the future for lifecycle assessment”

“We have started with collaboration and technology development to monitor, predict and optimise behaviour, for vessel lifecycle management and ongoing classification.”

Multiple layers of information, such as steel thickness measurements and performance data, can be stacked together in a digital model, which can be used for 3D class, predictive maintenance and data analysis.

“Virtual twins will help in the future for lifecycle assessment,” added Mr Sah. “They can be a single source of proof for all stakeholders with access to the same data and content for plan approval and advanced analytics.”

IR Class will continue to develop virtual twins enabling more opportunities for collaboration and increasing the efficiency of ship design, engineering and construction.

“This is the way forward for shipyards, class societies, naval architects and owners. We see 3D model-based classification replacing traditional 2D-based class,” said Mr Sah.

Future uses could include “predictive analysis, forecasting machinery failures, reducing downtime, simulating preventative actions and for health and emissions monitoring.”

Mr Bryhni explained how digital twins are used in maritime and offshore applications, enabling greater simulation of operations, better maintenance decisions, improved vessel efficiency, better crew training and to implement remote and autonomous technologies.

“Digital twins support operational decisions, such as when to maintain engines or replace filters, and using vessels most optimally,” said Mr Bryhni.

Owners can use digital twins to decide when to clean hulls, overhaul engines and replace engineroom components. They can be used by naval architects to optimise hulls, and test structural integrity and stability. Digital twins can be used for crew training, helping seafarers to operate vessels more effectively, understand advanced systems and test out scenarios of complex operations in a simulator before implementing them.

Another use case for digital twins is in remote and autonomous vessel operations. Digital twins of unmanned vessels can be used in remote operating centres to support their operation.

“Digital twins give people the best understanding of how vessels behave, replicating experiences on vessels in operation centres,” said Mr Bryhni.

When digital twins are built, they require data from live operations, input from crew and sensors to remain updated.

“A practical challenge is getting high-quality data for use cases and analysis”

“We need standardised data models of vessels in fleets. We run a high number of simulations with a digital twin to gain confidence in the model.”

For different use cases, smaller, purpose-built models could be required, such as to analyse ship propulsion or to train crew on daily operations and prototype offshore activities such as heavy-lift operations.

This will focus on enabling remote control of semi-autonomous vessels where a digital models of vessels and ship systems is needed.

“People will have to be involved,” said Mr Bryhni. “There will be humans in the loop and people on board, so we will need effective human-machine interfaces to help operators interact with autonomous vessels.”

For these operations, vessels will need strong satellite communications through very small aperture terminals and low Earth orbit constellations feeding real-time information into these digital twins.

“We see research is ongoing and developments are evolving in tying these things together for the lifecycle of vessels,” said Mr Bryhni. “There will be a lot of research happening in this area over the next few years.”

Webinar poll results

Attendees were asked to vote on a series of poll questions during the webinar. Here is a summary of the results.

How familiar are you with virtual twin technology in maritime operations?

Very familiar – already using it: 13%

Somewhat aware – exploring possibilities: 43%

Heard of it – but unsure where it fits: 35%

Not familiar at all: 9%

Which outcome would you prioritise most with a virtual twin?

3D classification for faster and more accurate plan approval: 10%

Structural integrity and direct strength analysis: 19%

Predictive maintenance and voyage optimisation: 62%

Sustainability, ESG and lifecycle assessment: 9%

Which collaboration challenge is most important to address with a virtual twin platform?

Establishing a single source of truth for stakeholders: 19%

Integration with legacy systems: 17%

Faster approvals and improved transparency: 9%

Data-driven decision-making and analytics: 55%

In your organisation, where do you see digital twin technology having the greatest potential?

Design: 23%

Operational decision support: 54%

Training: 9%

Other: 14%

In your opinion, when digital twin deployments fail, what is the most likely reason?

Weak use cases: 18%

Inadequate models or applications: 23%

Poor data quality: 59%

(source: Riviera Maritime Media)

On the panel of Riviera’s Digital Twin Integration: From Concept to Fleet-Wide Value webinar were (left to right): Indian Register of Shipping chief technology officer Rabindra Sah and Kongsberg Maritime vice president for special projects and product line manager for performance and fleet management, Anders Bryhni.

Riviera’s Maritime Navigation Innovation Webinar Week will be held 24-26 November. Use this link for more information and to register for these webinars.

Related to this Story

Events

© 2024 Riviera Maritime Media Ltd.