Business Sectors

Events

Ship Recycling Webinar Week

Contents

Fincantieri: Road to Net Zero

During the 2025 Seatrade Cruise Global, Fincantieri and Viking announced the first cruise ship in the world to be powered by hydrogen stored onboard for both propulsion and onboard electricity generation, thanks to a revolutionary fuel cell marinized container.

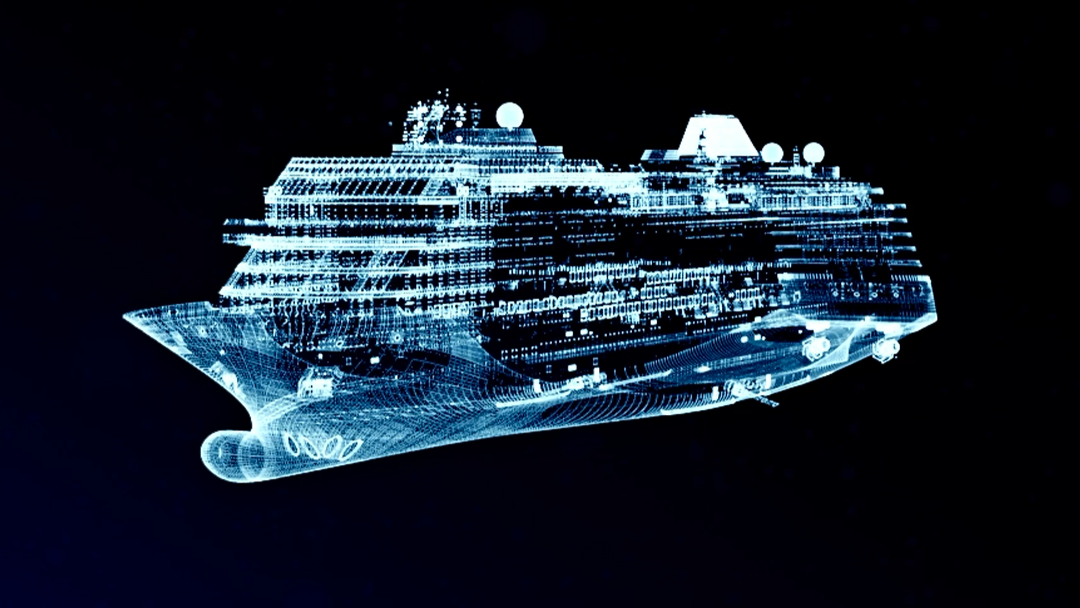

Fincantieri, a global leader in shipbuilding, is at the forefront of innovation applied to sustainability. The Group’s commitment to creating the “ship of the future” is a fundamental strategic pillar aimed at transforming the naval sector, making it greener and more technologically advanced. The ambition is to develop technological, safe and efficient ships that simultaneously respect the environment and improve the quality of life on board through cutting-edge digital solutions.

With the 2023-2027 Industrial Plan, the Group has outlined a clear path to achieve these goals, focusing on technologies related to alternative fuels, such as liquefied natural gas (LNG), hydrogen, fuel cells, and digitalization in general. According to Fincantieri’s CEO, Pierroberto Folgiero, the Industrial Plan “expresses the ambition to establish ourselves as world leaders in the construction and lifetime management of the ship of tomorrow, which we see as a fully-fledged floating smart city, a platform characterized by digital and green content”.

In recent weeks, Fincantieri has unveiled several groundbreaking innovations that contribute to shaping the strategy of the ship of the future.

During the 2025 Seatrade Cruise Global, Fincantieri and Viking announced the first cruise ship in the world to be powered by hydrogen stored onboard for both propulsion and onboard electricity generation, thanks to a revolutionary fuel cell marinized container. She is “Viking Libra”, currently under construction at the Fincantieri Ancona shipyard, with delivery scheduled for late 2026. The system is modular and scalable, converting hydrogen into clean energy. It can generate 6 MW of power and marks a milestone that sets the foundation for systemic change and supporting vessels of all sizes.

With a gross tonnage of approximately 54,300 tons and a length of 239 meters, the “Viking Libra”, will accommodate up to 998 guests in 499 staterooms. Designed with sustainability in mind, the ship will be capable of navigating and operating with zero emissions, allowing it to access even the most environmentally sensitive areas. This marks a new state-of-the-art hydrogen propulsion system that, combined with advanced fuel cell technology, will be capable of producing up to 6 megawatts of power, and will set a new benchmark for the industry’s decarbonization efforts. Viking’s subsequent ocean ship, the “Viking Astrea”, which is also currently under construction at the Ancona shipyard and scheduled for delivery in 2027, will also be hydrogen-powered.

The success of this joint initiative with Viking is made possible by Fincantieri’s capability to integrate new distributed technologies on board. A key contributor to this effort is Isotta Fraschini Motori, which will provide tailor-made solutions for the “Viking Libra”. The vessel will feature first-of-a-kind solutions to load and store hydrogen directly onboard the ship thanks to a containerized system to overcome supply chain constraints. Hydrogen will power proton-exchange membrane (PEM) fuel cells system specifically optimized for cruise operations, designed and produced by IFM. This achievement reinforces IFM’s role as a leader in the adoption of green fuels and cutting-edge energy systems for the maritime and land application sectors.

In this project, the auxiliary power generation system is based on PEM fuel cells powered by hydrogen, to be used as an alternative to traditional engines. The adopted configuration allows for zero-emission operations in port and in the most environmentally sensitive areas. In detail, the system includes 2 removable tanks of liquefied hydrogen (LH2), which feed 2 PEM fuel cell containers of about 3 MW each, these are supported by a battery system designed to manage load fluctuations through peak shaving—a strategy that reduces power demand during peak periods to lower energy costs and enhance system stability.. The electrical power of the PEM fuel cells will be 6.3 MW (2 x 3.15 MW), and the battery capacity will be 4.7 MWh. This operational profile will allow a “zero emission” mode to be used in protected areas, such as the Norwegian Heritagefjords, that will include 3 hours of navigation at 10 knots and 10 hours in port. The annual reduction in emissions will be approximately 20% compared to a ship using fossil fuels, considering an LH2 refuel every 2 days. The adoption of removable LH2 tanks, which can be easily transported via truck, allows for the immediate effectiveness of the system, even in the absence of a consolidated logistics of hydrogen provision in the main cruise ports.

Fincantieri is also developing a second project with a power generation system based on SOFC (Solid Oxide Fuel Cell) fuel cells powered by a hybrid H2/LNG system, to be used in combination with dual-fuel LNG/MGO engines. Unlike PEM fuel cells, SOFCs can internally reform LNG before using it to generate electricity. This internal reforming capability allows the system to utilize existing LNG infrastructure while preparing for a future in which green hydrogen becomes more widely available. During this transitional phase, LNG serves as a bridge fuel, enabling decarbonization today while positioning the technology for a seamless shift to pure hydrogen operation as global supply chains mature and hydrogen bunkering becomes widespread. The goal is to apply such first hybrid hydrogen/LNG concept on ships to be delivered in 2027.

With these two projects Fincantieri demonstrates its effort in the decarbonization of the industry and takes a step forward in becoming the first shipbuilding group in the world to design hybrid hydrogen cruise ships. The initial goal of these projects is to develop and build eco-friendly cruise ships integrating hydrogen-based technologies.

These achievements are the result of a long-term planning of R&D and experimental activities, starting from the experience developed by applying fuel cells to submarines, then evolved with the manufacturing and testing of the Zeus laboratory ship project (the world’s first prototype powered by fuel cells).

Still during the Seatrade Fincantieri presented Navis Sapiens, a new shipbuilding paradigm that introduces the concept of the “smart ship”. Navis Sapiens is an advanced digital ecosystem, based on scalable, modular and open platforms, that transforms ships into true cognitive units, capable of “learning” new languages and functionalities throughout their lifecycle.

This capability, which utilizes artificial intelligence, big data, and connectivity, will allow the ships not only to make better decisions in real-time, optimize efficiency and ensure the highest levels of safety and sustainability, but also to leverage technologies that are currently immature or unknown and will become available in the near future.

Therefore, ships equipped with Fincantieri’s Navis Sapiens will not face digital obsolescence. On the contrary, they will gain increasing value over time. From the shipowners’ perspective this is a revolution, because a ship with a brain is a product that evolves, developing ever-new business capabilities that can be installed or updated on board during its operational life, rather than being a product for which investment is necessary to preserve its initial capabilities.

In fact, one of the main objectives of Navis Sapiens is to minimize long-term investment (the total cost of ownership) for Fincantieri’s customers, while allowing the best functional integration and interoperability. Moreover, the prerogatives of Navis Sapiens, founded on open platforms that can be accessed and populated by involved parties, will facilitate communication among all the ship’s stakeholders, both on board, improving the experience of passengers and crews, and on land directly involving the docking port, the Port Authority, the land supply chain and the relevant commercial network.

Fincantieri developed Navis Sapiens with the goal of creating a new generation of ships, equipped with a digital architecture capable of analyzing large amounts of real-time data from thousands of sensors. This system allows the unit to learn from its operational models to constantly improve efficiency and safety, optimize the route, consumption, maintenance and management of onboard systems, and adapt to different operational conditions. A Navis Sapiens can also communicate with the mainland and other vessels, with the aim of creating an interconnected fleet.

Navis Sapiens is based on intelligent architecture that integrates a series of advanced technologies. At the core of this system are Artificial Intelligence and Machine Learning, which enable analysis of real-time operational conditions and optimization of the ship’s performance. They are supported by the Internet of Things (IoT), facilitating interconnected management of onboard systems for continuous and predictive monitoring. Another key component is the Digital Twin, a digital simulation that replicates the ship’s behaviour in various scenarios, thereby enhancing maintenance and safety. Finally, advanced automation reduces the margin of human error and improves operational management, ensuring more efficient and secure operations.

Navis Sapiens is also a contribution to fleet sustainability and resilience. Indeed, a central aspect of the project is its contribution to the green transition for emission reduction in the maritime sector. The proposed solutions include optimizing onboard energy consumption, as well as intelligent management of waste and ballast water, minimizing the impact on marine ecosystems. With the increase in digitalization, cybersecurity becomes a priority. Navis Sapiens introduces a new approach to onboard cybersecurity, as well as technologies capable of improving risk management, with predictive systems for maintenance or continuous safety monitoring on board through sensors and AI. The first ship equipped with Navis Sapiens is expected to enter service by the end of 2025.

With the first delivery of its SeaQ Bridge system aboard the cruise vessel Mein Schiff Relax, delivered by Fincantieri last February, the subsidiary Vard Electro introduced a fully digitalized and ergonomically optimized solution that sets a new benchmark in bridge design, bridge systems integration and shipboard operations within the cruise industry. The group’s highest level of bridge integration is a bridge solution with an extended architecture, utilizing a combination of integration solutions, combined with optional touch monitors to gather various systems into one operator station.

The project is the result of a close collaboration between shipowner, shipbuilder, technology supplier, navigational officers and the crew, ensuring a seamless integration of design, construction and system implementation tailored for the needs of a modern cruise vessel.

The SeaQ Bridge is type-approved by DNV, one of the world’s leading classification societies, ensuring compliance with the highest maritime standards. For each project, a separate test is conducted in collaboration with class, and ship owners, ensuring that the system meets specific operational requirements. The process has started to have approval in RINA as well.

What sets the SeaQ bridge as benchmark is its integration of key shipboard systems, including also third-party solutions, into a centralized human-machine-interface (HMI), operable via touchscreens featuring intuitive apps and drag-and-drop functionality.

This setup allows operators to configure personalized layouts, granting immediate access to critical functions. Importantly, the number and arrangement of screens on the bridge are now determined by customer requirements, rather than system limitations, offering a tailored solution that aligns with specific operational needs.

Designed for scalability, the SeaQ Bridge integrates additional applications – such as intercom directories and alarm management – and supports the development of new functionalities as operational needs evolve, while also allowing existing systems to expand.

The SeaQ Bridge system extends its advanced capabilities to the Safety Command Centre, featuring a large video wall composed of 55-inch multi-displays, each capable of four-way splits, providing operators with a complete overview of critical systems. Dedicated workstations ensure each operator access to essential controls and information.

This integrated SeaQ approach supports coordinated action and faster decision-making across the ship. The same concept is applicable to the Engine Control Room (ECR). All relevant systems from the traditional ECR are now integrated into a common interface. This redundant solution offers user-driven flexibility without compromising system reliability.

In every aspect, this installation demonstrates how digitalization, collaboration, and smart design can transform cruise ship automation and navigation systems. With Mein Schiff Relax, Vard Electro, TUI Cruises, and Fincantieri have created a solution that sets a new standard for future cruise ships.

Also, SeaQ, as well as Navis Sapiens, contribute to Fincantieri’s strategy to evolve from Physical vessel design authority to Digital vessel design authority, strengthening its leadership position in technological innovation applied to shipbuilding and to the whole shipping industry.

All these milestones are part of the broader industrial transformation plan of the Fincantieri Group, which aims at an increasingly intelligent, adaptive, scalable and connected model, integrating the most advanced digital technologies to contribute to making shipbuilding increasingly innovative, sustainable and globally competitive.

Related to this Story

Events

Ship Recycling Webinar Week

International Bulk Shipping Conference 2025

Tankers 2030 Conference

Maritime Navigation Innovation Webinar Week

© 2024 Riviera Maritime Media Ltd.