Business Sectors

Events

Ship Recycling Webinar Week

Contents

Metalcolour delivers DOBEL® Film Laminated Steel for Disney Destiny

Metalcolour has been entrusted to deliver approximately 200,000 square meters of Film Laminated Steel for interiors including cabins, corridors, wet rooms, and doors for the Disney Destiny

Recently, Disney Cruise Line announced the name of their next cruise ship in the Wish-class – Disney Destiny. Metalcolour has been entrusted to deliver approximately 200,000 square meters of Film Laminated Steel for interiors including cabins, corridors, wet rooms, and doors. Disney Treasure is an impressive 144,000-ton LNG/electric-powered cruise liner and will be the 8th ship in the Disney Cruise Line fleet. With capacity for 4,000 passengers, she is projected to begin operations in 2026. We at Metalcolour are excited to follow the new ship’s future adventures.

If you have ever stepped foot on a cruise ship you have almost certainly touched one of our products. Metalcolour leads the market in laminated metals for the marine industry, so even if you haven’t heard of us, we’ve definitely been in contact. We have recently celebrated our 50th anniversary giving us the opportunity to look back on how much we have achieved, at the same time as looking forward to how much more we want to progress. The origins of Dobel by Metalcolour lie in response to a market desire.

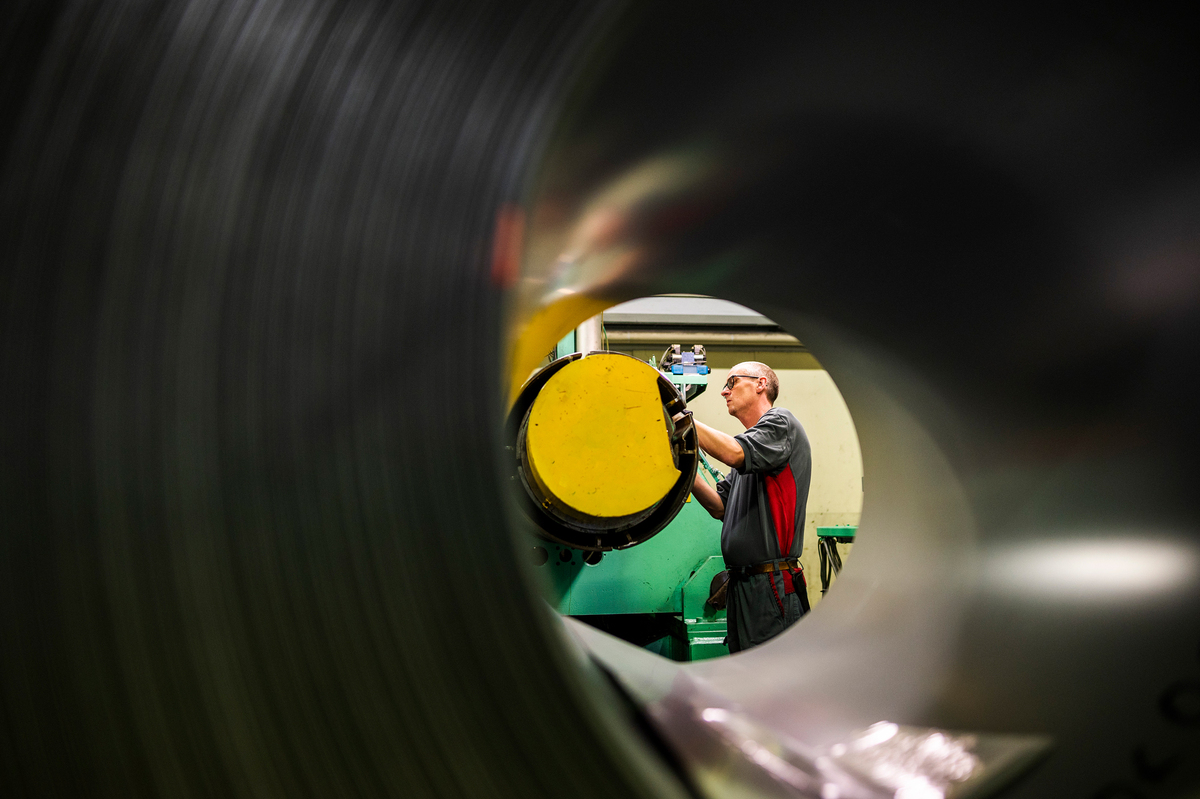

Over the years we have developed several innovative solutions in cooperation with customers and partners. We are proud to be one of the first companies within the industry to develop a fully certified fire-proof laminated steel. We are also one of the first companies to offer heat applied protective film and maybe the only one to always offer this for all our products. Heat applied film is easily removed and leaves no residues whatsoever. And after years of focused dedication we have driven down the minimum order size to just 10m2, the lowest in the industry by a very large margin. However, we consider ourselves essentially the same company after all these years. We laminate on sheet metal, we laminate on coiled metal and we do so with flexibility and expertise in order to deliver the very best for our customers.

The entire team at Metalcolour shares the passionate belief that there is a way to do things better – to deliver faster, to be more flexible, to reach higher standards. This led us to develop our very own set of guarantees, a number of assurances to our customers guaranteeing delivery times, quality standards and even gloss finishes. These self-imposed standards were previously unheard of within our sector and have not come from external industrial committees. We do all this not just to provide the very best service and products to our customers but to set ourselves standards to be exceeded in order that we may become a little bit better tomorrow than we are today.

Many industries recognise that Scandinavian manufacturing has some of the highest standards in the world and Metalcolour is very pleased to play a role in that strong tradition. Alongside a safe and healthy work environment we continually work towards lowering our impact on the natural environment. We now offer laminated metals with a bio-sourced PVC made from Pine Oil, a renewable by-product of the wood pulping industry, sourced from sustainably managed forests. We exclusively purchase fossil-free electricity and use river water instead of drinking water in our cooling processes, this water returns to the river with no impact to the river’s health. We are also a certified zero-pollution clean air company having entirely removed harmful solvents from our production process. “Made in 100% in Scandinavia" is a standard we are very proud to meet.

We live in an increasingly fast-paced world overly influenced by data, reorganisation and market disruption. At Metalcolour we hope you are not disappointed when we say that we reject those values in favour of consistency, continuity and personal connections. Dobel by Metalcolour has built its dependable brand on reliability, quality and partnership but then again, you probably already know that.

Dobel by Metalcolour, here today and here tomorrow.

Related to this Story

Events

Ship Recycling Webinar Week

International Bulk Shipping Conference 2025

Tankers 2030 Conference

Maritime Navigation Innovation Webinar Week

© 2024 Riviera Maritime Media Ltd.