Business Sectors

Events

Offshore Wind Webinar Week

Contents

Wärtsilä Shaft Line Repair Services: people behind the process

In the event of a major incident, such as a collision, grounding, fire or a flood, a quick and targeted response is critical in avoiding and maintaining damages. To mitigate risks like these, Wärtsilä Seals & Bearings offers a range of specialist services under the solution – Wärtsilä Shaft Line Repair Services

To help reduce further damage and ensure safer operations for the future, Wärtsilä Seals & Bearings provides a centralised, cross-functional project management approach. Our approach relies on positioning alignment specialists, project managers and our wide product portfolio and service network at the right time and place to ensure customer needs are efficiently addressed.

Typically, customers contact us when they are experiencing a problem with their shaft line. This can range from hearing a noise along the shaft line, vibrations on components, a leaking seal or a worn or overheating bearing. When addressing an incident, alignment specialists provide expert investigations which allows Wärtsilä to accurately determine the work which needs to be performed on a shaft line.

The team consists of analysts and specialist service engineers who have experience working on complete shaft lines and associated equipment. Through specialist training provided by Wärtsilä, engineers develop their skills and expertise to become qualified alignment engineers. They are supported by our global team, who are experts at diagnostics, analytics, calculations and measurements. Our specialists can be deployed within hours of being contacted by the customer and are in constant communication with project managers to support the project.

Following this, our project managers co-ordinate the repair by ensuring all necessary parts and services required for the repair are scheduled and delivered efficiently to limit customer costs and ensure the vessel is back in operation as soon as possible.

Our competitive edge is founded on having one of the widest product and service portfolios on the market. This, combined with having a strategic footprint in our manufacturing plants enables us to produce products and spare parts locally and deliver them quickly to site. Our wide and global reach of service engineers means we can provide resources at the right place and time. Through Wärtsilä Shaft Line Repair Services, we pull all these elements into a project in order to deliver very efficiently for our customers.

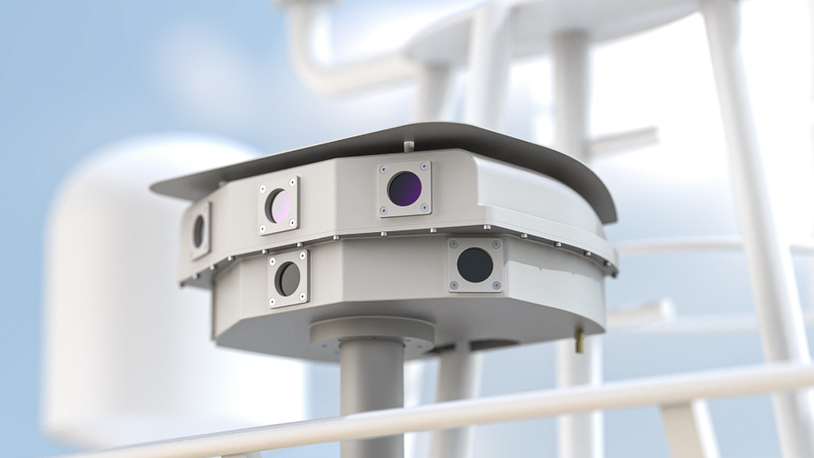

In addition to reactive services for urgent issues, we also provide preventative services such as our Wärtsilä Portable Condition Based Monitoring System. This service enables customers to investigate the alignment of their shaft line without taking the vessel out of operation. We install the equipment and it monitors the shaft line for a usual sailing under all normal operating parameters and conditions of the vessel. The data is then analysed, and a report of recommendations is sent to the customers on any work required.

Wärtsilä Shaft Line Repair Services is focused around providing fast, efficient and project-managed shaft line solutions. We would encourage vessel owners and operators to contact us should they be experiencing even what they might feel are minor issues, such as noise and vibration, as these can lead to much bigger problems if not addressed.

Related to this Story

Events

Offshore Wind Webinar Week

Maritime Decarbonisation, Europe: Conference, Awards & Exhibition 2025

Offshore Support Journal Conference, Americas 2025

© 2024 Riviera Maritime Media Ltd.