Business Sectors

Events

Contents

Register to read more articles.

ABS, HD Hyundai Mipo sign digital development deal

A South Korean shipbuilder is working with a classification society to develop a smart shipyard

HD Hyundai Mipo (HMD) intends to use artificial intelligence (AI), communication technologies, digital twins and robotics, among other digital technologies, in its future smart shipyard.

The South Korean shipbuilder is working with classification society ABS to develop digital manufacturing-based automation equipment for shipyards after signing a joint development project (JDP) agreement to focus on smart technology within HMD’s shipyard operations.

ABS said it would use its Guide for Smart Technologies for Shipyards to help HMD to identify opportunities for process improvement, focusing on key features such as hyper-connectivity, advanced automation and data-driven intelligence.

“Cutting-edge technologies are revolutionising shipyard production, pushing boundaries and unlocking new possibilities,” said ABS chairman and chief executive Christopher Wiernicki.

“Smart features are enhancing health, safety and quality processes, allowing efficiency and innovation in modern shipbuilding,” he said.

“From augmented and virtual reality to 3D engineering, AI-based simulation, digital twins, robotics and automation, these advancements are shaping the future of smart ships and smart shipbuilding,” Mr Wiernicki added.

The JDP outlines the potential for additional certifications from ABS, such as software for product design or manufacturing assessment, provided all necessary criteria are met.

“With this joint development project, we aspire for the digital manufacturing initiative spearheaded by Mipo to receive objective evaluations from certification bodies and establish itself as a global standard,” said HMD president and chief executive Hyung Kwang Kim.

The collaboration could also lead to improved procedures in shipyard operations and survey processes, efficiencies beneficial to both ABS and HMD.

Sign up for Riviera’s series of technical and operational webinars and conferences:

- Register to attend by visiting our events page.

- Watch recordings from all of our webinars in the webinar library.

Related to this Story

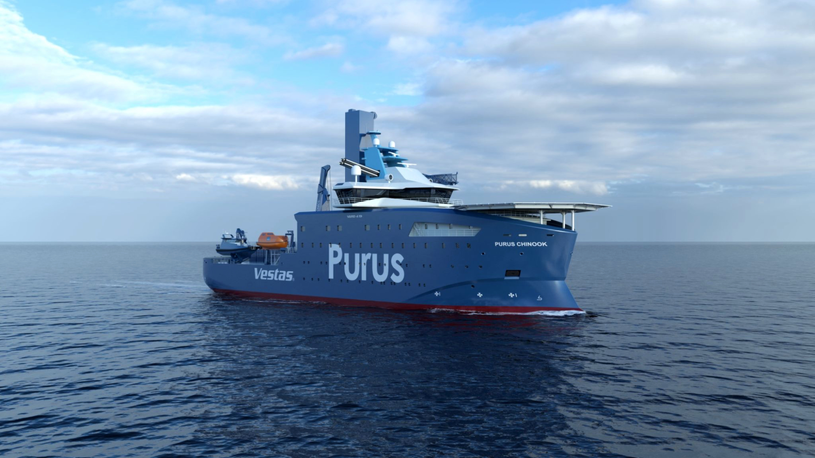

AI, digital twins help design cyber-secure, green SOVs

Events

Offshore Support Journal Conference, Americas 2025

LNG Shipping & Terminals Conference 2025

Vessel Optimisation Webinar Week

© 2024 Riviera Maritime Media Ltd.