Business Sectors

Events

Contents

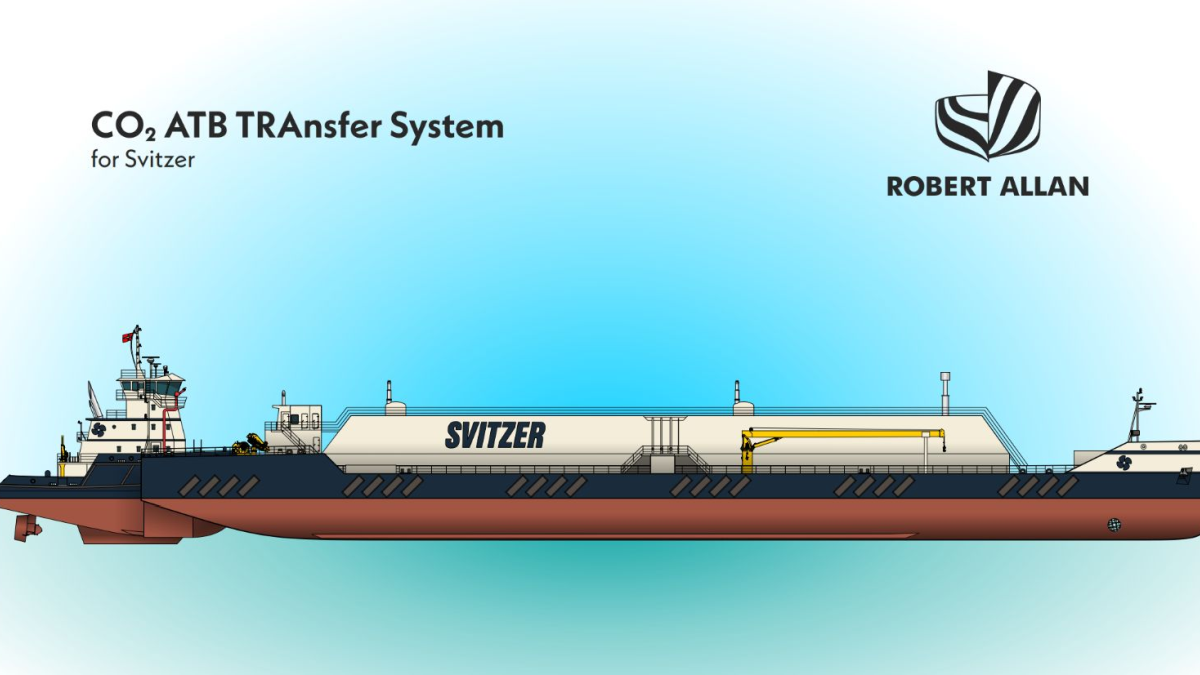

ABS classes Svitzer's CO2 transport, storage ATB design

A Danish shipowner and Canadian naval architect have secured class approval for their design of an articulated tug-barge unit to transport CO2

Svitzer has entered the CO2 transport market with a class-approved design for an articulated tug-barge unit to support carbon capture and storage (CCS) projects.

ABS has granted an approval in principle (AiP) for the AP Moller subsidiary’s barge, which can both store and transport liquefied CO2 with support from a pusher tug.

Svitzer sees this ATB concept design as a missing link in sustainable CCS that would minimise the need to build onshore storage tanks and cut emissions from transporting CO2.

“Getting the approval from ABS indicates our chosen design concept meets essential safety and regulatory standards,” said Svitzer head of CO2 transport Sofie Skotting.

“That validation is important in our quest to be a preferred partner for oil and gas majors and other stakeholders involved in CCS projects.”

Svitzer worked with British Columbia, Canada-based Robert Allan Ltd on the design of the modular tug-and-barge system that can be scaled to incorporate one or two tanks and would have a low draught for access to ports with shallow water without requiring additional towage assistance.

“Transport and storage of captured CO2 is going to be a cornerstone of the industry’s drive to reduce carbon emissions,” said ABS chief commercial officer and executive vice president Vassilios Kroustallis.

“Svitzer’s innovative liquefied CO2 ATB solution is going to play an important role in realising the potential of carbon capture technology and supporting its adoption.”

Svitzer’s tug-barge solution would have an overall length of 88 m if there is one tank and 130 m for two tanks, with both options having a beam of 28 m, a draught of less than 6 m and a sea speed of 12 knots.

It would have capacity to store 3,850–7,800 m³ of liquefied CO2 at a medium pressure and could sail in seas with maximum wave heights of 7 m.

The concept would involve loading liquefied CO2 at an offshore or coastal site into the barge’s storage tanks, attaching a pusher tug to the barge, pushing it across seas to the CCS project’s location and then detaching the tug.

This barge can act as floating storage or can rapidly discharge at a hub or storage site and be moved back to the CO2 source by the pusher tug.

Riviera’s CO2 Shipping, Terminals and CCS Conference, APAC, will be held in Kuala Lumpur, Malaysia, 30 March 2026. Click here for more information on this industry-leading event.

Related to this Story

Events

Maritime Regulations Webinar Week

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

© 2024 Riviera Maritime Media Ltd.