Business Sectors

Events

Contents

Register to read more articles.

Challenges for harbour vessel decarbonisation

Vessels operating in ports including tugs, pilot boats, supply vessels and line boats should not be overlooked in the maritime industry’s decarbonisation drive

Much of the industry’s emissions-reduction attention is focused on sustainable oceangoing ships, but the sector must also cut pollution in ports from harbour craft.

Regulators in North America, Europe and Singapore in particular have focused on the impact shipping pollution has on local populations and have introduced legislation to cut NOx, SOx, carbon monoxide and particulate matter emissions. In the last 10 years, their attention has turned to carbon.

The California Air Resources Board’s (CARB) new compliance requirements for the at-berth regulation came into effect this year, while the EU Fit for 55 was, according to the European Tugboat Association, one of the “most important challenges” it faces.

Meanwhile, the Maritime Port Authority of Singapore, where there are over 1,200 harbour craft, has put the pressure on owners and operators to transition from conventional propulsion to cleaner alternatives by 2030, with a complete phase out by 2050.

Despite these regulations, the vast majority of vessels in port use auxiliary engines burning gasoline or diesel to generate power at berth.

According to e1 Marine managing director Robert Schluter, this shows there are barriers to the adoption of alternative power and fuels in port for these vessels.

“For shipping’s decarbonisation battle, a concentrated focus on the first and last mile can offer a positive example to the rest of the industry,” he said.

Mr Schluter said the key barrier to decarbonising tugs and workboats in port is “untaxed marine fuel is still currently the cheaper option compared to electricity.”

“Port and terminal operators need additional and more accessible subsidies and incentives to implement new systems"

The lack of affordable capital to invest in modernising facilities is another contributor. According to analysis from Bank of America and universities in California, one of the biggest challenges associated with port electrification is the high upfront costs and lack of funding to support the installation of grid and charging infrastructure.

“It is apparent that electrifying tugs, workboats and other harbour craft, which are ideally suited for battery power due to their operating profiles, is being hampered due to the lack of charging infrastructure and grid support,” said Mr Schluter.

“Port and terminal operators need additional and more accessible subsidies and incentives to implement new systems and train employees in their use,” he continued. “Until then, electricity connections in many ports remain a stumbling block, with several ports lacking the infrastructure to connect vessels to the grid or having their connection compromised with close ties to nearby major cities with their substantial electricity demand spikes.”

He noted the lack of reliable, sustainable shoreside power impacts smaller vessels as much as large oceangoing ships.

Owners of tugs and other harbour vessels are working to reduce their carbon footprints and are looking at options such as shore power, onboard batteries and alternative fuels when they are available.

HaiSea Marine is a prime example, as it has invested in a fleet of all-electric and LNG-fuelled tugboats and a dedicated onshore power supply and recharge station at a new LNG export terminal in British Columbia.

But the vast majority of newbuild tugs continue to feature diesel engines which emit local air pollutants and greenhouse gas (GHG) emissions. These harmful emissions are increasingly coming under the gaze of regulators.

A new port power solution

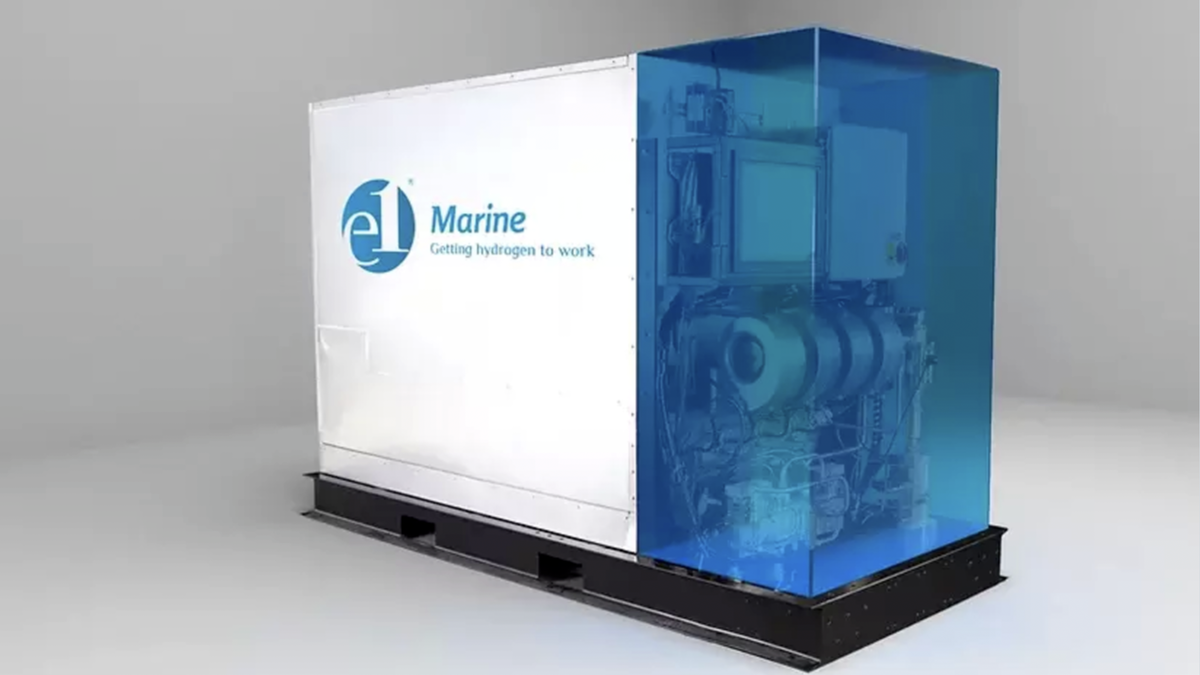

Mr Schluter said dedicated power supply solutions do not need to be hampered by the lack of grid support and network infrastructure. e1 Marine’s containerised methanol to-hydrogen generator offers an alternative solution that does not require an infrastructural overhaul and competition with competing off-takers.

“The containerised unit’s design must be adopted to fit local markets and conditions, not just in terms of product output, voltage and frequency, among others, but also in compliance with local regulatory requirements, port authorities and state international marine regulations,” he said.

“This makes the regulatory hurdles of introducing new technology into ports vast and complex with this variety of stakeholders, but not insurmountable when the benefits to business and society are so significant.”

"There is a reluctance to be a first mover and trial the use of new solutions"

Therefore, the successful development and implementation of cleaner shoreside power “is ultimately dependent on collaboration and new working methods between all stakeholders, yet there is a solution that can cut through the complexities of grid reliance,” said Mr Schluter.

“Change is happening, and although there is a reluctance to be a first mover and trial the use of new solutions, it is evident that ports that are not improving their resilience and sustainability risk losing business that will be hard to attract back.”

The 27th International Tug & Salvage Convention, Exhibition & Awards will be held in association with Caterpillar in Dubai, UAE, 21-23 May 2024. Use this link for more details of this industry event and the associated social and networking opportunities; and this link to book your ticket for the exhibition, social gatherings and awards night.

Related to this Story

Events

Maritime Environmental Protection Webinar Week

Cyber & Vessel Security Webinar Week

The illusion of safety: what we're getting wrong about crews, tech, and fatigue

Responsible Ship Recycling Forum 2025

© 2024 Riviera Maritime Media Ltd.