Business Sectors

Events

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

Contents

Electrifying near-shore FLNG installations

As floating LNG players explore innovative power solutions, clear guidance keeps safety the top priority while pursuing operational and environmental objectives, writes Terrance Roberts, ABS business development manager, global offshore

Liquefied natural gas (LNG) is playing a central role in the future energy landscape, especially in power generation projects with reduced carbon emissions. Floating LNG (FLNG) installations offer a flexible solution for producing LNG offshore or nearshore, particularly where onshore facilities face infrastructure constraints.

An emerging approach involves electrifying near-shore FLNG installations by replacing or complementing traditional onboard power generation with an external power source. This method has the potential to reduce operating costs and improve energy efficiency. Additionally, outsourcing the power source decreases maintenance burdens on the installation operator, enhancing safety and operational stability.

Exploring external power sources

With the current global energy scenario of emerging economies and increased electrification, the energy industry is looking to expand natural gas production and availability to meet global demand. FLNG installations receive gas from offshore or onshore sources, process and liquefy it onboard, then store it for offloading to LNG carriers. This makes them an increasingly popular solution to replace onshore gas liquefaction plants, to monetize stranded gas offshore and to support communities lacking onshore infrastructure.

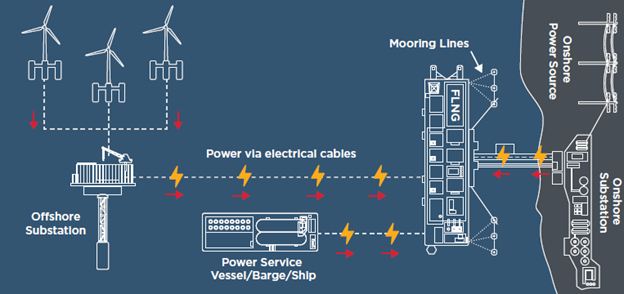

Future-ready FLNG players are exploring external power sources such as shoreside utilities, onshore generators, power service vessels and offshore windfarms to power installations to curb greenhouse gas (GHG) emissions and significantly cut costly offshore fuel dependency.

The ABS safety report, Powering Near Shore FLNG Installations from an External Source, issued in August 2025, supports owners, operators, designers, shipyards equipment and systems manufacturers, integrators and regulators in navigating the design considerations for FLNG electrical power systems that rely on these external power sources. By following goal-based standards and conducting thorough risk assessments, the offshore energy industry can continue to implement this technology and innovate while maintaining the highest safety standards.

A framework for novel FLNG power systems

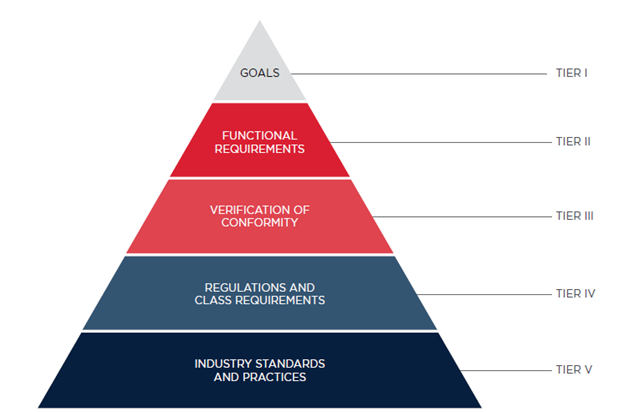

ABS applies a goal-based standards (GBS) approach[i] to novel concepts without a proven service history, such as externally powered FLNG installations. This framework helps verify that new technologies achieve an equivalent level of safety to conventional designs through clearly defined safety goals, functional requirements that support those goals, and risk assessments to identify and mitigate hazards.

The GBS framework consists of five tiers, from high-level safety goals down to specific regulations and industry practices. It also provides a structured path for classifying novel FLNG power systems, giving stakeholders confidence that safety is maintained while onboarding new technology.

When goal-based approaches are used for compliance with administration and coastal state requirements, authorities should be contacted directly or through the class society to understand the extent to which they will consider alternatives to conventional requirements.

Safety goals and functional requirements

The above ABS report establishes safety goals across seven key areas:

1. Power generation and distribution goals promote safe and reliable electrical power for all operational requirements, with fail-safe features preventing progressive failure.

2. Fire safety goals focus on preventing fire and explosion occurrence through proper equipment selection and hazardous area management.

3. Structural goals maintain integrity under environmental conditions and operational loads anticipated during the design life.

4. Personnel safety goals protect crew from hazards associated with machinery and systems, particularly high-voltage equipment.

5. Safety management goals establish procedures for safe operations and emergency situations while also confirming that crews are qualified and trained.

6. Automation goals help ensure that control, monitoring and safety systems perform as intended and provide equivalent safety from remote locations.

7. Security goals help achieve cyber-resilient installations that can withstand operational technology threats.

Each goal is supported by specific functional requirements that translate safety objectives into actionable design criteria. For example, main power sources must have sufficient capacity for all operational modes, emergency power systems must be independent of main power, and electrical equipment must operate within the power quality envelope.

Power system design considerations

LNG production requires substantial energy – liquefying one kilogram of natural gas consumes around 0.25 kilowatt-hour (kWh) of power. That means an installation designed to process 5 million tonnes per annum (MTPA) of LNG would require approximately 140 megawatts (MW) of electrical power.

External power can come from land-based grid supply, renewable onshore or offshore energy sources, power service vessels or a combination of these sources.

A hybrid power system configuration with a combination of conventional marine power sources such as diesel and gas engines or turbines and non-conventional sources can be designed to meet the reliability and redundancy requirements of FLNG installation projects.

Installations located near shore can take advantage of the power from the main power grids or localised energy sources based on wind, solar, hydro, fuel cells or nuclear power plants. A combination of these sources is known to offer high reliability and availability and are more efficient from a sustainability perspective than the onboard power generation systems.

The number of power connection lines from the external source depends on project risk tolerance, source reliability, environmental factors and hazards associated with power loss.

An important consideration, external power supply should be supplemented by backup local power generation onboard the installation to immediately support essential services and safety-critical loads if external power is lost. Duration of the backup system’s availability should be designed based on evacuation plans, project risk tolerance, risk associated with loss of process systems, environmental assessment and Classification rules and requirements in the installation area.

ABS’s aforementioned publication covers three FLNG configurations with specific technical advisories for:

1. FLNG with propulsion and accommodation.

2. FLNG without propulsion but with accommodation.

3. FLNG without propulsion and without accommodation.

Additional installation criteria

Power transmission from external power sources uses ultra-high voltage or high voltage alternating current or direct current subsea or overhead cables. This choice depends on distance from the external source, transmitted power requirements, space constraints and cost considerations.

With incoming UHV/HVAC power from the external power source, installations require an external power switchboard and step-down transformer, along with mitigation measures for voltage variation, resonance and reactive power generation by subsea cables.

Cable support structures also must maintain optimal cable length that minimises slack while preventing excessive tension. The support system must avoid interfering with mooring systems and other equipment while accommodating the full range of the FLNG installation’s draught and tidal variations.

The ABS approach offers an opportunity to use recognised industry standards in the design and construction, with consideration for thermal and electrical monitoring and distance protection relays.

Reference the ABS report for more details covering:

· Power quality.

· Power system studies.

· Reverse power protection.

· Electrical equipment arrangement and design.

· Emergency disconnect and disengage.

· Automation and cyber resilience.

Documenting hazards and risk

FLNG owners and operators exploring electrification can look to class society publications to address complex operations that demand rigorous adherence to established safety standards. Floating LNG assets combine high-voltage electrical systems with cryogenic liquefied gas in a dynamic marine environment – a combination that creates compounding hazards where conventional offshore electrical practices may be insufficient.

Conducting a comprehensive hazard and risk assessment is essential to identify how electrical system failures could trigger cascading events affecting personnel, the environment or asset integrity. This assessment must systematically evaluate how equipment failures, operational errors or other external factors can lead to dangerous scenarios.

All foreseeable hazards, their root causes, potential consequences and risk controls must be thoroughly documented. At a minimum, some aspects that must be addressed include: equipment layout, arrangement and location; mechanical faults, electrical faults and human errors; electrical shock precautions; cybersecurity gaps; flammable and toxic gas dispersion and other environmental factors. Additionally, some of the hazards specific to this novel concept include damage to external power supply cables, loss of any single component in the stationkeeping/mooring system, extreme weather conditions and impact or collision, among others.

A safe global energy transition

Keeping safety at the forefront of decision-making is essential risk management for novel and new technologies that have no direct precedent in either traditional offshore oil and gas or onshore LNG facilities.

ABS’ publication addresses critical aspects – from power system configuration to goal-based standards – to help ensure externally-powered FLNG installations protect personnel health and safety, offshore and nearshore assets and the environment.

As leaders of the offshore classification industry, ABS offers information and reports to address critical aspects – from power configurations and systems design to safety and environmental protection systems – with an innovative goal-based approach. These principles represent a path to class and statutory compliance based on specific characteristics and risk profile, providing a customised approach to novel technology. Once implemented in the design criteria and systems configuration, the ABS requirements would provide a solid basis for project development, helping to ensure externally powered FLNG installations protect personnel health and safety, offshore and nearshore assets and the environment.

Download the report for a deeper dive into powering near-shore FLNG installations from an external source.

[1] The ABS GBS approach is based on the International Maritime Organization (IMO) MSC Circ. 1394, Generic Guidelines for Developing IMO GBS, and extensive experience with novel concepts, new technology qualifications and risk-based methodologies.

Sign up for Riviera’s Floating Energy Forum on 14 May 2026 in London:

Related to this Story

Events

Maritime Regulations Webinar Week

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

© 2024 Riviera Maritime Media Ltd.