Business Sectors

Events

Contents

Integrated simulation improves LNG vessel efficiency, cuts emissions

Gamma Technologies and CLEOS present complementary strategies for optimising propulsion and power on LNG carriers using system-level modelling

Integrated system simulation is emerging as a core enabler of propulsion efficiency and emissions reduction across a vessel’s operational life, particularly in the context of LNG carrier operations.

This was the central theme of a 15 May 2025 Riviera webinar How integrated system simulation is revolutionising vessel power generation and propulsion efficiency on LNG carriers and other vessel types hosted in association with Gamma Technologies, which brought together Gamma’s application and sales leads with development input from CLEOS, the R&D arm of three prominent Greek shipowners.

Gamma Technologies application lead for mobility systems and integration Michael Zagun opened the session with an overview of Gamma’s modelling platform, which supports digital twin strategies across marine and mobility sectors.

Mr Zagun explained “Physics-based simulation enables you to master the integration of alternative fuels on the R&D side,” noting the platform’s ability to model power generation, fuel reforming, battery integration, waste heat recovery, and exhaust gas after-treatment under both static and transient conditions.

A case study from Gamma’s user base demonstrated how a virtualised single-cylinder engine testbed can mimic full engine behaviour using real-time simulation. This enables a faster development cycle and reduced prototyping costs, with the digital twin acting as a real-world proxy.

“This approach is already being used by a major main engine manufacturer,” said Mr Zagun, referencing a presentation at Gamma’s user conference.

From a shipowner perspective, CLEOS development engineer George Pontikakos presented a detailed modelling and optimisation project carried out using Gamma’s GT-SUITE.

CLEOS serves the LNG, dry bulk and crude fleets of GasLog, DryLog and Olympic Shipping, and is tasked with pursuing vessel energy efficiency and emissions reduction across those fleets.

CLEOS developed a modular simulation model of a modern LNG carrier which included propulsion engines, auxiliary generators, steam production systems, cargo reliquefaction, and hydrodynamics.

The model was then used to compare operational scenarios across a typical 15-day transatlantic LNG voyage, with the aim of quantifying the benefits of generator engine optimisation.

“Instead of using multiple generator engines at low load, we modelled a scenario where fewer engines were run closer to optimal capacity,” said Mr Pontikakos.

The results, derived without hardware modifications, indicated a 64% reduction in generator gas consumption and a 12% reduction in marine diesel oil consumption. This equated to a 2.7% decrease in total LNG fuel use, a 3% decrease in MDO use, and a 13% reduction in generator-based CO2 emissions.

“These are not trivial results when you consider they stem purely from operational optimisation,” he said.

Addressing questions from the audience, Gamma Technologies EU sales director Dr Haitham Mezher, noted the industry’s challenge was not only meeting IMO’s net-zero strategy but also adapting system designs dynamically across each vessel’s life.

“It boils down to three things: reducing energy consumption, maximising conversion efficiency, and using the right mix of green energy sources. Simulation is key to managing the wide range of operational conditions and system interdependencies involved.”

Dr Mezher highlighted the importance of long-term model validity and adaptability, “Digital twins must be capable of evolving with the asset – accounting for component ageing, retrofits and changes in operating profile. That is why modularity and data-driven recalibration are essential design principles.”

Both presenters agreed their respective approaches – CLEOS’s operational modelling and Gamma’s component-to-system multi-physics simulations – are not in conflict. “Optimisation is needed both at the design and operational phase,” said Mr Pontikakos. “System-level models help us assess energy-saving technologies and plan for newbuild decisions, while also guiding retrofits and voyage planning.”

Mr Zagun added simulation environments need to remain practical and accessible, “We support model democratisation through cloud services and user interfaces that allow non-specialists to apply predictive models and optimise systems on board. This is how we make digital twin concepts actionable in daily operations.”

As the IMO framework and regional decarbonisation regulations tighten, integrated simulation is likely to become a default tool in both ship design and operational decision-making.

The poll responses revealed a sector actively grappling with the implications of decarbonisation and digitalisation.

While only 18% of participants reported immediate plans to integrate emerging technologies, a combined 82% were either observing trends (29%), promoting one or more technologies (32%), or assessing their impact across fleets (21%).

When asked which simulation application areas held the greatest relevance, integration of alternative fuels led by a considerable margin (43%), followed by alternative propulsion and storage (23%).

Performance optimisation was the dominant priority for digital twin deployment, selected by 87% of respondents, compared with just 5% for fault detection and 8% for failure prediction.

Although 45% of the audience had already considered simulation for operational optimisation, a further 23% indicated they had not yet done so, suggesting room for broader uptake.

Notably, 80% stated IMO’s regulatory direction was prompting them to seek more advanced fleet monitoring solutions – confirming the rising strategic importance of predictive, system-level modelling tools.

The panel concluded with a call for ongoing collaboration. “The industry is moving through rapid and complex changes,” said Dr Mezher. “No one model fits all use cases. But combining component precision with system-level optimisation will be central to future-ready vessel operations.”

Related to this Story

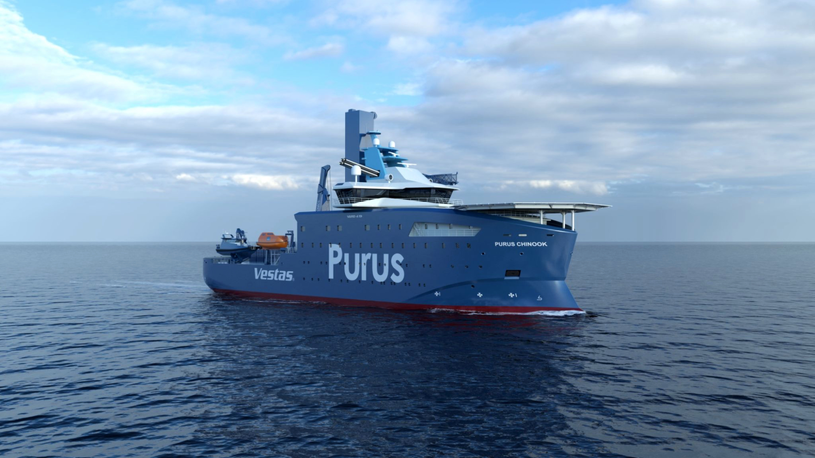

AI, digital twins help design cyber-secure, green SOVs

Events

Offshore Support Journal Conference, Americas 2025

LNG Shipping & Terminals Conference 2025

Vessel Optimisation Webinar Week

© 2024 Riviera Maritime Media Ltd.