Business Sectors

Contents

Register to read more articles.

Introducing ‘the most significant ship design intervention in more than a century’

A radical reimagining of vessel propulsion is gathering momentum, spearheaded by a collaborative effort from the American Bureau of Shipping (ABS), Thordon Bearings, Wärtsilä Shaft Line Solutions, the Shanghai Merchant Ship Design and Research Institute (SDARI), and the National Technical University of Athens

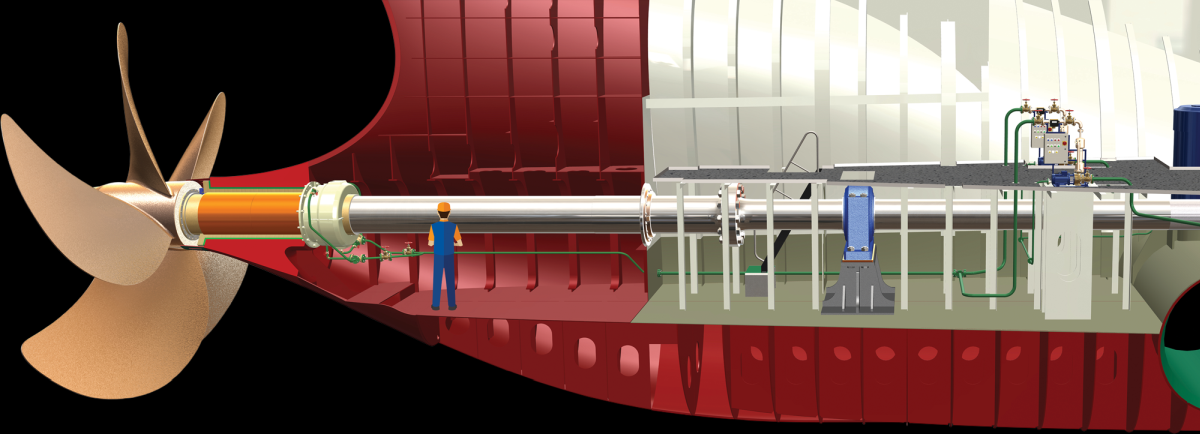

Their alliance has resulted in a sterntubeless ship design featuring a single seawater-lubricated bearing, a concept the project partners believe will revolutionise conventional oil-lubricated systems while meeting rigorous environmental standards.

The central innovation is Thordon’s Blue Ocean Stern Space (T-BOSS), which replaces the traditional sterntube propeller shaftline system with a dry chamber accessible by surveyors or technicians. This novel configuration provides direct access to a seawater-lubricated bearing and seal, enabling inspection and maintenance to be conducted while the vessel remains afloat with no shaft withdrawal required.

This fundamentally alters established maintenance protocols, eliminating the costly and time-intensive requirement for shaft withdrawal or drydocking, a capability Thordon technical director, Anthony Hamilton says "has never before been possible".

The genesis of the design is firmly rooted in tackling the environmental vulnerabilities inherent in traditional oil-lubricated propeller shaft systems, which carry the risk of oil leakage stemming from seal damage or wear.

Speaking on the December ABS podcast Innovation in Ship Design: Sterntubeless Vessels, Thordon Bearings vice president of business development Craig Carter observed that historically, attention has predominantly focused on emissions from the smoke stack, with comparatively less emphasis on "what’s happening below the waterline in shipping". The sterntubeless design directly confronts this issue, aiming to "eliminate a source of pollution below the waterline".

ABS vice president of technology Chris Leontopoulos underscored the fundamental appeal of seawater as a lubricant, highlighting its ready availability and "zero-carbon footprint”. He also noted the significant operational disruptions and financial burdens associated with oil seal failures, which can result in vessels requiring towage for essential repairs.

ABS has played a key role in formalising the requirements for this innovative design, publishing specific guidelines in June 2024 and introducing the ABS STBLess-W Notation. This classification is awarded following verification the vessel meets defined criteria, including a dry stern inspection chamber, a split-type water-lubricated bearing and a seawater cooling and conditioning system with built-in redundancy.

Compliance with the Guide for Enhanced Shaft Alignment and the Class Notation TCM-W are mandatory prerequisites for achieving the STBLess-W Notation. Dr Leontopoulos emphasises the design is fully ABS Rule compliant, explaining existing ABS regulations were robust enough to support approval without requiring entirely new rules.

Beyond the environmental advantages, the sterntubeless design also presents compelling economic benefits. Through modifications to the vessel’s aft end, including the creation of a bulkhead opening, adjustments to structural stiffeners, and a shortening of the intermediate shaft, shipbuilders can realise "reductions in weight, material and labour costs”, according to Mr Hamilton.

Mr Carter indicates while the initial capital expenditure is "about the same as an oil-lubricated system, the opex is really, really lower”. Thordon projects potential savings exceeding US$1M over a vessel’s operational lifespan, factoring in reduced fuel consumption, lower drydocking and maintenance expenditures, optimised shaft alignment and potential for increased cargo capacity.

A key operational advantage arises from the ready accessibility of the bearing and seal within the dry chamber. This facilitates routine inspections and maintenance, including bearing replacement if needed, without necessitating the vessel’s removal from service in a drydock.

Dr Leontopoulos contrasted this with traditional vessels where accessing tail shaft bearings requires a complex and potentially hazardous process of dismantling the shaft line. The sterntubeless arrangement comprehensively "addresses all these issues”, encompassing both the risk of pollution and accessibility for inspection and maintenance.

While the sterntubeless concept presents a promising trajectory for the industry, certain challenges persist. Dr Leontopoulos acknowledged for very small vessels, the stern inspection chamber might be too restricted for practical human access, limiting the benefits of onboard maintenance.

Mr Carter highlights the crucial need to "educate shipyards and naval architects around the world" about this fundamental change to the vessel’s aft end. He notes a prevailing lack of familiarity with water-lubricated shaft lines in many yards, with the open nature of the seawater-lubricated system being "very foreign to many newbuilding shipyards around the world”.

Despite these initial hurdles, industry engagement has been encouraging. Mr Carter revealed Thordon has already submitted quotation requests for T-BOSS to major shipbuilders in China and South Korea for container ships and gas carriers. He reported "very, very high" interest from shipowners and shipyards globally, including in Europe, the USA and Canada.

Speaking on the sidelines of the SeaAsia exhibition in Singapore, Thordon Bearings regional manager for the Asia Pacific, Sam Williams, said Chinese and South Korean yards’ receptiveness to the design’s potential derived in large measure from the streamlined construction processes and the significant long-term operational advantages it offers to their clients.

Mr Williams emphasised the reduced reliance on consumables like lubricating oil and the elimination of costly emergency seal repairs are key selling points in Asia. He also pointed out the potential for engineroom reconfiguration due to the shorter shaft line, which can lead to enhanced cargo capacity, particularly for owners in the bulk carrier and tanker segments.

While no vessels currently feature this sterntubeless design, Mr Carter expressed optimism about the prospect of imminent orders, noting overwhelmingly positive feedback from shipowners who consider the concept a "no-brainer”. Echoing this view, Dr Chen Kang of SDARI reports "considerable market interest" since ABS granted approval in principle in 2022 and attributes this to the systems environmental credentials.

The sterntubeless design directly addresses increasingly stringent environmental regulations, particularly within United States waters, where the Vessel General Permit encourages or mandates the elimination of the oil-to-sea interface.

While the adoption of water lubrication is not currently factored into Energy Efficiency Design Index (EEDI), Energy Efficiency Existing Ship Index (EEXI), or Carbon Intensity Indicator (CII) calculations, it directly mitigates the risk of oil pollution, which carries substantial penalties.

Thordon’s Mr Hamilton summarises the overall advantages succinctly, calling the sterntubeless ship design featuring water-lubricated bearings "the most significant ship design intervention in more than a century”.

Sign up for Riviera’s series of technical and operational webinars and conferences:

- Register to attend by visiting our events page.

- Watch recordings from all of our webinars in the webinar library.

Related to this Story

Events

International Bulk Shipping Conference 2025

Tankers 2030 Conference

Maritime Navigation Innovation Webinar Week

© 2024 Riviera Maritime Media Ltd.