Business Sectors

Contents

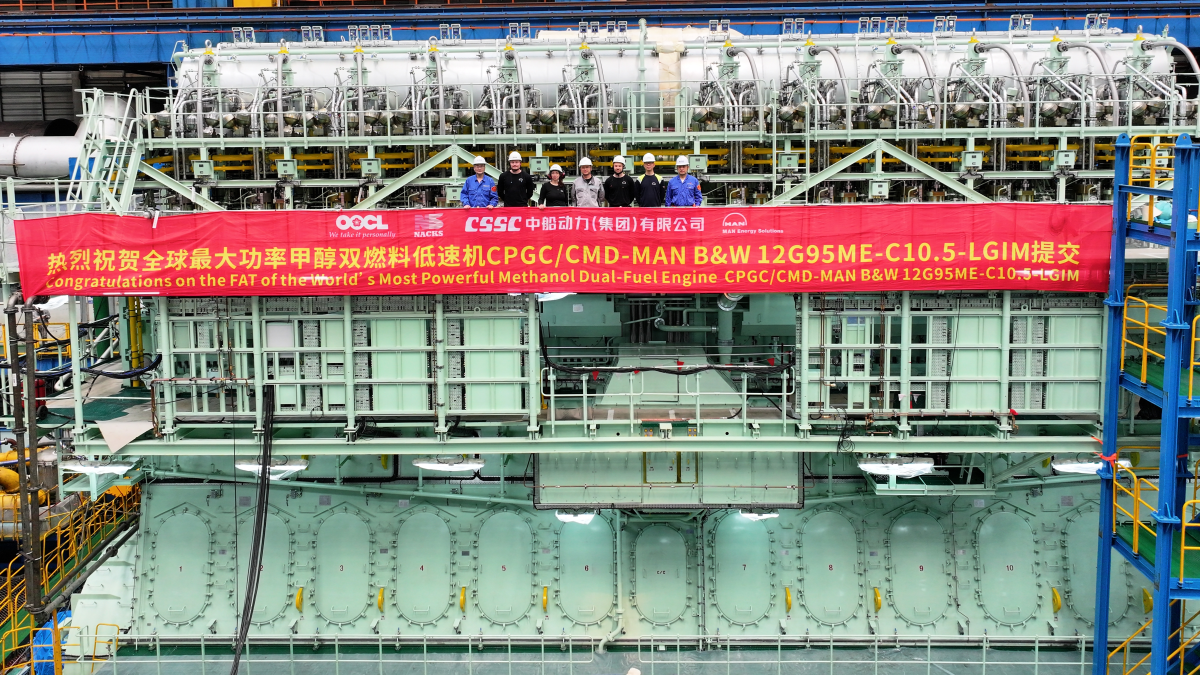

MAN set to deliver 'world's most powerful methanol engine'

Under construction in China, is the first of a dozen 82,440 kW slow-speed engines that will power a series of container vessel newbuilds

MAN Energy Solutions’ (MAN ES) first liquid gas injection methanol (LGIM)-based MAN B&W 12G95ME-C10.5 engine is nearing completion and, when delivered, will be the "world’s most powerful methanol engine" in operation, according to the company.

Under construction by Chinese licensee CSSC-MES Diesel Co, the engine is the first of 12 that will power a dozen 24,000-TEU container vessels for a pair of shipowners.

Seven of the vessels are being built for Orient Overseas Container Line (OOCL) at Nantong COSCO KHI Ship Engineering Co, and the remaining five are under construction at Dalian COSCO KHI Ship Engineering Co for COSCO Shipping Lines Co.

MAN’s ME-LGIM engine series has several years of real-world, seagoing operational experience, with the engines being used by methanol carriers, according to MAN ES two-stroke sales head Christian Ludwig.

"To date, between newbuild engines and retrofits, we have won over 230 ME-LGIM references that have accumulated over 600,000 hours running on methanol alone. With ME-LGIM technology reaching 10 years in the market, it represents [a] mature, proven technology,” he said.

The dual-fuel engines work on the Diesel principle, and when operating on green methanol, offer carbon-neutral propulsion for large merchant-marine vessels, according to the company.

"This latest, remarkable milestone – the world’s most powerful methanol engine... harness[es] the potential of methanol... and we fully expect methanol to figure prominently as a future-fuel across all segments," MAN ES two-stroke business president Bjarne Foldager said.

Successful type-approval test for MAN dual-fuel engines

MAN has also had a successful type-approval test (TAT) on its dual-fuel MAN L35/44DF engine.

The engine is designed for application in auxiliary gensets and electric propulsion at constant speeds, respectively, of 720 and 750 rpm, MAN ES said.

The TAT involved testing both 35/44DF variants, namely the methane-capable 35/44DF CD and the methanol-ready 35/44CD. MAN said testing took place in April at the Changwon headquarters of South Korea’s STX Engine with a panel of six classification societies observing.

The L35/44DF CD engine is an upgraded version of the L35/44DF CR engine, first launched in 2015. Among other features, the engine comes equipped with an adaptive combustion control system that monitors the state of combustion in real time for optimal fuel-injection conditions.

MAN ES senior vice president Alexander Knafl said, “We have worked closely with STX over the past three years in developing the MAN 35/44DF CD. We anticipate it having broad appeal, especially among container vessels and LNG carriers. In addition to its strong output, other advantages of the MAN 35/44DF CD include its effective reduction of methane slip and its future-fuel readiness for methanol and other fuel types.”

MAN said the new genset aims to reduce shipowners’ capital expenditure and operating costs, with the company claiming the engine can reduce methane slip by up to 85%.

Sign up for Riviera’s series of technical and operational webinars and conferences:

- Register to attend by visiting our events page.

- Watch recordings from all of our webinars in the webinar library.

Related to this Story

IMO’s net-zero plan poised to pressure ageing fleet with rising costs

Events

TUGTECHNOLOGY '25

Reefer container market outlook: Trade disruption, demand shifts & the role of technology

Asia Maritime & Offshore Webinar Week 2025

Marine Lubricants Webinar Week 2025

© 2024 Riviera Maritime Media Ltd.