Business Sectors

Contents

Register to read more articles.

Partnership tackles technical challenges of large liquid CO2 carriers

A partnership of shipbuilders, a steel maker, class and flag will develop the technology, design and rules for large liquid CO2 carriers to support the growth of carbon capture, utilisation and storage (CCUS)

Under a memorandum of understanding (MoU) signed in Seoul on 27 August, POSCO, Hyundai Mipo Dockyard, Korea Shipbuilding & Offshore Engineering, Lloyd’s Register (LR) and the Liberian International Ship & Corporate Registry (LISCR) will develop liquid CO2 (LCO2) carriers in excess of 20,000 m3 by 2025.

Through this MoU, POSCO will develop new steel material and relevant technology for the storage tank, which are core technologies for the LCO2 carrier, while HMD & KSOE will develop the ship design, welding and processing technology for the ship’s construction. Additionally, LR will review and revise the relevant classification rules of the certification for the new steel materials and approve the basic design of the ship. The Liberian Registry is in charge of all flag state approval procedures such as establishing ship registration regulations and acceptance of ports entry.

With the push towards carbon neutrality, the need for technologies related to CCUS is growing. According to a report by the International Energy Agency, as of 2020, 40M tonnes of CO2 is captured annually, most of which is permanently stored in geological formations or re-injected into oil wells to improve oil recovery. Based on an analysis by the Global CCS Research Institute, 3.6 giga tonnes per year of carbon dioxide need to be captured and stored to reach net-zero emissions.

This means the current global CCUS capacity of 40 mega tonne capacity needs to be increased by 100 times for the carbon-zero goal will be realised. However, there are still no international standards, guidelines and certifications for large LCO2 carriers to transport carbon dioxide to storage facilities, from materials to ship construction.

Among the technologies needed are new steel materials that can withstand the low temperature and high pressure required by the large size of CO2 storage tanks, as well as welding materials and application technologies.

POSCO Energy and Shipbuilding Materials Marketing office head Sang-Cheol Kim said the steel maker expects “to preoccupy the carbon-neutral market by developing new materials for the large-scale CO2 carriers through close collaboration with customers and participating companies, and supporting technology for using steel materials.”

HMD and KSOE are in charge of designing and manufacturing the carriers, meaning 100% localised technology in South Korea will be applied from steel material development and shipbuilding.

“This is a very important project for the entire maritime industry, as this type of vessel will play an important part towards the successful implementation of upcoming maritime environmental and emissions regulations,” said LISCR chief operating officer Alfonso Castillero. “The industry needs to be forward looking and focused on leveraging technology to ensure our industry continues to be as modern, safe and efficient as possible. This project is a major step in this direction,” he added.

Riviera Maritime Media will provide free technical and operational webinars in 2021. Sign up to attend on our events page

Related to this Story

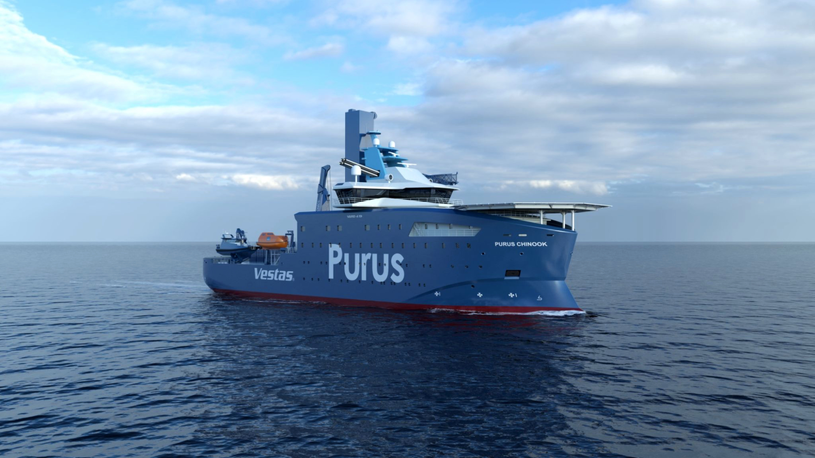

AI, digital twins help design cyber-secure, green SOVs

Events

Offshore Support Journal Conference, Americas 2025

LNG Shipping & Terminals Conference 2025

Vessel Optimisation Webinar Week

© 2024 Riviera Maritime Media Ltd.