Business Sectors

Events

Contents

Register to read more articles.

OCCS lifecycle findings reshape decarbonisation strategy

Project COLOSSUS offers the full-chain lifecycle assessment of shipboard carbon capture, revealing its nuanced emissions impact and regulatory implications

Project COLOSSUS has published the most comprehensive lifecycle assessment to date of onboard carbon capture and storage (OCCS) technologies, raising critical questions about deployment pathways, cost and regulatory alignment.

Developed by the Global Centre for Maritime Decarbonisation (GCMD) with support from the Oil and Gas Climate Initiative (OGCI - a consortium of leading international oil and gas companies that collaborate on efforts to accelerate the industry’s response to climate change) and Stena Bulk, the study centres on the OCCS system installed on the MR tanker Stena Impero under Project REMARCCABLE.

By accounting for emissions across the entire carbon value chain – from fuel production to the eventual storage or utilisation of captured CO2 – Project COLOSSUS offers a granular view of the trade-offs involved in OCCS adoption.

The findings underscore the importance of distinguishing between apparent emissions reductions at the point of capture and net well-to-wake (WtW) savings when upstream and downstream emissions are included.

"The maturity and immediate applicability of monoethanolamine (MEA)-based systems makes them the reference case," said GCMD. “However, even with MEA capture and a 40% gross capture rate, the net WtW GHG emissions savings amount to only 28.5% when installed on a heavy fuel oil (HFO)-fuelled ship.”

This baseline is derived from a practical limit imposed by onboard space constraints for liquid CO2 storage. While higher capture rates are technically possible, they require storage volumes that most ships cannot accommodate.

The study calculated the cost of avoiding each tonne of CO2 under these constraints at between US$269 and US$405, excluding potential cargo loss due to reduced space on board.

Importantly, the study explores three distinct downstream scenarios: permanent storage, incorporation into concrete, and production of e-methanol.

Utilising captured CO2 in concrete yields a net emissions savings of 60% when credits are fully assigned to the ship, primarily due to the displacement of cement. In contrast, using the same CO2 to produce e-methanol delivers up to 91% emissions savings for the vessel consuming the fuel, but only 17% savings when credits are assigned to the ship that captured the carbon.

A more favourable emissions profile emerges when OCCS is combined with biofuels. When used cooking oil-derived biodiesel powers the vessel, net WtW emissions savings can reach 121%. Similar results are observed for bioLNG and biomethanol, with respective emissions reductions of up to 98% and 119%.

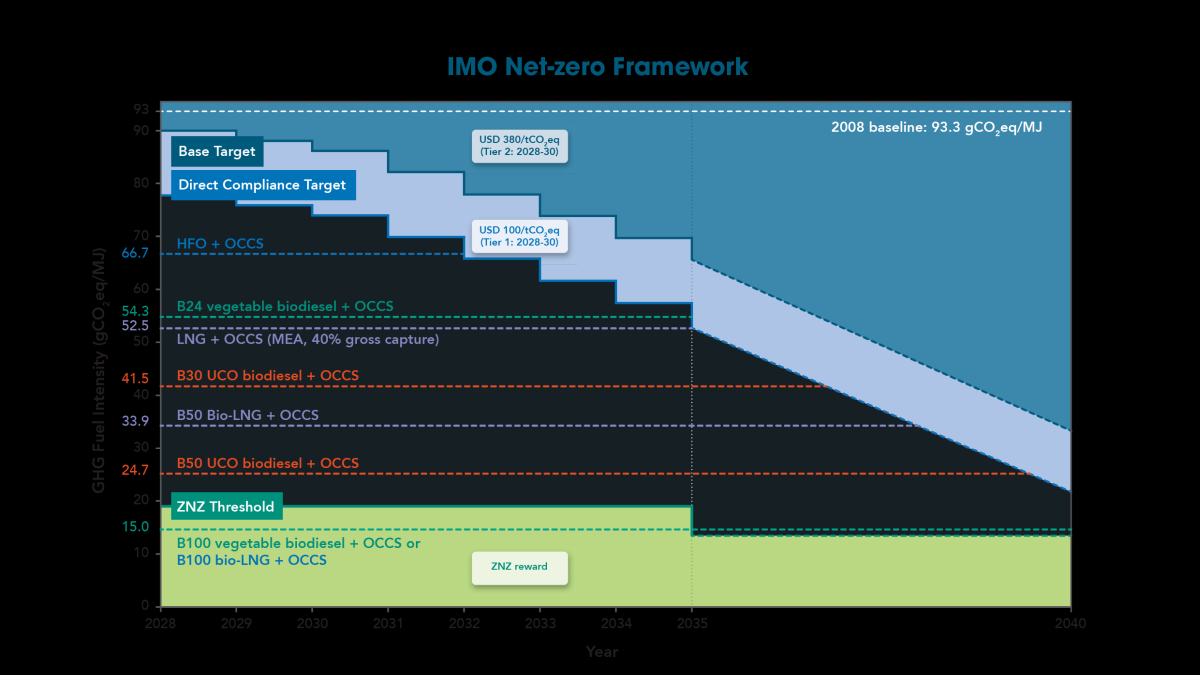

The findings also offer a pathway for interpreting OCCS under IMO’s forthcoming GHG Fuel Intensity (GFI) framework.

Although MEPC 83 did not clarify how OCCS-derived reductions are to be accounted for, the study proposes an “equivalent GFI” approach. Under this methodology, HFO-fuelled ships with 40% OCCS can remain compliant until 2032, while LNG-fuelled ships extend compliance to 2035.

When fossil fuels are entirely replaced by biofuels, OCCS-equipped vessels could meet 2040 GFI targets.

Project COLOSSUS represents an essential step in setting a quantifiable emissions benchmark for OCCS.

Yet, its authors are clear, "OCCS cannot be viewed in isolation. Its emissions abatement must be assessed holistically across fuel types, onboard operations, and post-capture pathways to inform coherent policy and investment decisions."

The full report can be downloaded here.

Sign up for Riviera’s series of technical and operational webinars and conferences:

- Register to attend by visiting our events page.

- Watch recordings from all of our webinars in the webinar library.

Related to this Story

Events

Maritime Regulations Webinar Week

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

© 2024 Riviera Maritime Media Ltd.