Business Sectors

Contents

Register to read more articles.

New HVAC solutions following Covid-19

The pandemic has led to new solutions and priorities for cruise and ferry HVAC

Covid-19 has had a huge impact on heating, ventilation and air conditioning (HVAC) solutions for passenger ships, leading to new technologies and trends.

Indeed, trends have changed focus – before the pandemic, the HVAC focus was energy saving, but now it is passenger safety in terms of protecting them against germs and viruses. As Koja Marine director Esko Nousiainen says, “Before the pandemic, we tried to reduce the amount of fresh air in many cases and tried to save energy, but now it is not energy saving, it is passenger safety that is more important. That is the trend, keeping people safe. There are more sophisticated solutions being used and developed to get rid of germs and viruses.”

Mr Nousiainen singles out the use of UV lamps and ionisation that kills viruses and germs. “We are following what the owners want and installing this equipment in our factory. We have a few projects in the US, one of them is a ferry company, where we are providing this kind of technology.”

There are, however, challenges to retrofitting cruise ships with new HVAC solutions. Mr Nousiainen says “The most important thing is to retrofit to make cruising for passengers safer. We cannot change that much as it is very expensive to rebuild the HVAC systems on board, we have to use the technology that is available.”

He gives an example, “We are installing ionisation in fan coils in public spaces, as they circulate public area air and we are cleaning, infiltrating and cooling down the air. That is the most efficient way to keep passengers safe in public areas.”

Anti-viral HVAC solutions

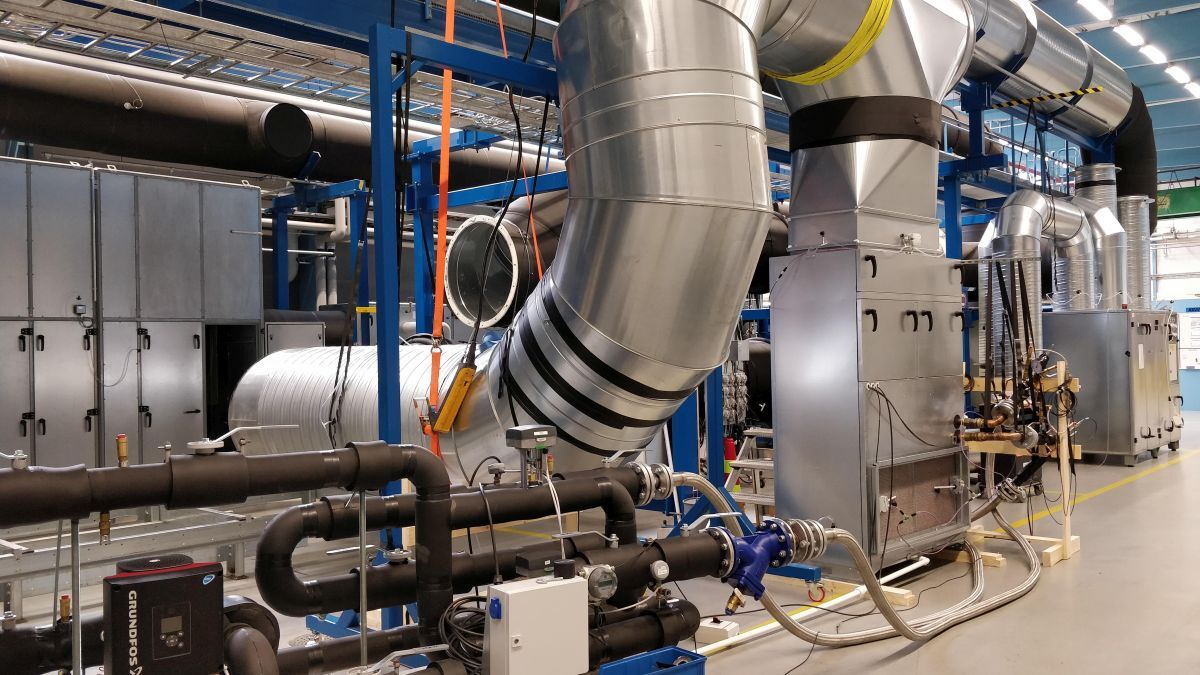

Koja Marine is installing anti-viral HVAC solutions in its factory in the coming months.

Looking ahead, he comments, “A couple of years after Covid, people will be vaccinated and the focus will again be on energy savings.”

Current projects Koja Marine is involved in include the TUI newbuild at Meyer Turku and Tallink’s MyStar LNG dual-fuelled fast ferry currently being built. The company is also providing the HVAC solutions for Wasaline’s Aurora Botnia and has signed a contract for the fourth Oasis-class vessel to be built at Chantiers de l`Atlantique.

Elsewhere, Halton Marine director Sami Piirainen tells PST, “This unfortunate pandemic has brought more attention to the importance of clean indoor air. This will be taken more into account now and in the future when planning HVAC for passenger ships. Nobody wants to see 400 major cruise ships sitting stand still on dock. In ideal world, one would only supply 100% fresh air on board but that is not possible, as it would have a major impact on the carbon footprint.

“There have to be good solutions to provide clean indoor air also from the energy consumption perspective. It comes down to good solutions, systems and procedures that provide safety and the wellbeing of people when we talk about indoor air.”

“The flip side of the pandemic is that people are now more aware of the importance of indoor air and manufacturers have to further develop their solutions or create new ways of keeping the indoor air cleaner,” says Halton Marine technology director Mika Kirjavainen.

“There are several solutions to improve the indoor air on board. The best solution for a specific project is usually achieved by a co-operation of the owner who knows their ship, the designer and the HVAC specialist, who has proven data on the solutions.”

When speaking of ventilation, Halton recommends a five-point list which includes utilising more fresh air, checking the air distribution, providing air purification systems, ventilating spaces with fresh air, especially between the events and technical maintenance to ensure air conditioning and air purification are functioning well.

Halton has launched several solutions as a result of the pandemic. One of these is the Halton Quattro Aero. “The technology has been available, but we further developed the concept and tested this system for ships to help to fight against the pandemic,” said Mr Piirainen.

Halton Quattro Aero is a new, patented innovative technology for both cabin and public space fancoils as well as other duct installations. Halton started the development of the Quattro Aero for the marine industry in co-operation with Finnish company Airforte in Q2 2020. Halton Quattro Aero provides filtration and disinfection technology specifically designed for ships’ fancoil systems. It is a four-stage-filtration system that has a combination of multiple and established air purification technologies. It consists of bi-polar ionisation, UVGI light, filtering and photo-catalytic oxidation. The modular construction enables the system to be installed close to nearly any size of fancoil, whether public or cabin fancoil or as duct installation.

“The onsite test installations of Halton Quattro Aero will be done on cruise ships with the final product ready for the market within the next months. This is a great choice, especially for future ships to enable wellbeing and excellent indoor air quality on board ships,” said Mr Piirainen.

The Halton UVGI-SA Halton Sentinel mobile unit is also a result of the pandemic. However, Halton has been working with UV light technology for over 20 years for air purification.

Halton offers two type of local mobile air filtration units for virus mitigation, to purify dedicated spaces. “Halton Sentinel UVGI mobile air filtration units have highly efficient UV-resistant air filters with a rating of MERV 13. Behind these filters are safe UV-C bulbs that do not produce any respiratory irritant ozone. These UV-C bulbs operate at the 254-nanometer wavelength. This wavelength is critical for its germicidal inactivation properties,” says Mr Kirjavainen.

The Halton UVGI overhead light has also been developed as a result of the pandemic. “Not as widely publicised, but also an area of concern for virus spread are contaminated surfaces. Aerolised virus that is generated by a cough or sneeze will ultimately settle out of the air over some time. The virus can live on these surfaces for hours or days. If someone walks by and brushes their hand on these surfaces and rubs their eyes, for example, the virus can spread to a new host,” says Mr Piirainen.

This kind of contamination is called fomite, and viruses on surfaces would be exposed to the UVGI overhead light for a short period to disinfect up to 99% of irradiated surfaces. The UVGI light neutralises the virus by preventing it from replicating, rendering it inert.

Elsewhere, Trident BMC has also developed HVAC products to meet the new requirements following the pandemic.

Formerly known as Trident Maritime Systems, the company decided that to better serve the unique requirements of its customer base and increase the competitive strengths, it would consolidate Baltec Marine and a portion of the ship systems’ business formerly known as Callenberg Technology. The new name after the merger is Trident BMC and includes all divisions under Baltec Marine as well as the energy management technology, marine conversions, HVAC marine newbuild and spare part departments of Callenberg Technology.

Mercy Ships HVAC

Trident BMC director, energy management technology, Magnus Hansson says “With experience of delivering the HVAC for Mercy Ships’ new hospital vessel currently under commissioning, we have a customised toolbox of solutions which we call holistic health solutions, supporting the different initiatives going on in the cruise and ferry industry for a return to sail. Our holistic health solutions portfolio supports the many initiatives going on. The focus is to have a good balanced HVAC plant, proper filtration and UV systems installed where required.”

Mr Hansson adds “Reporting and keeping track of the changes and status of the HVAC system is essential, therefore we have upgraded our HVAC surveyor app to include such a functionality for our holistic health solutions.”

Trident BMC has developed tailored HEPA frame conversion kits for integration in marine air handling units and tailored UV conversion kits as part of its holistic health solutions portfolio.

Mercy Ships has provided free surgeries and medical care to people in need for over 40 years. Its newest hospital ship, Global Mercy will be world’s largest civilian hospital ship when it is brought into service later this year and is set to more than double the surgical and training capability Mercy Ships provides. With six operating theatres, the 174-m, 37,000-tonne ship will house more than 600 volunteers from all over the world.

The company is set to deliver its HVAC solutions to Global Mercy in China in Q2 this year, and the commissioning of the HVAC systems are in their final stage.

Furthermore, Trident BMC’s newly developed HEPA frame solutions and UV concept are under installation on multiple ships presently.

Energy efficiency is still an important focus for Trident BMC. Mr Hansson says “We have been very active and have registered three patents for solutions to address the demands and requirement for filtration, UV, air balance and at the same time focus on energy efficiency.”

Related to this Story

Events

Offshore Wind Webinar Week

Maritime Decarbonisation, Europe: Conference, Awards & Exhibition 2025

Offshore Support Journal Conference, Americas 2025

© 2024 Riviera Maritime Media Ltd.