Business Sectors

Contents

Register to read more articles.

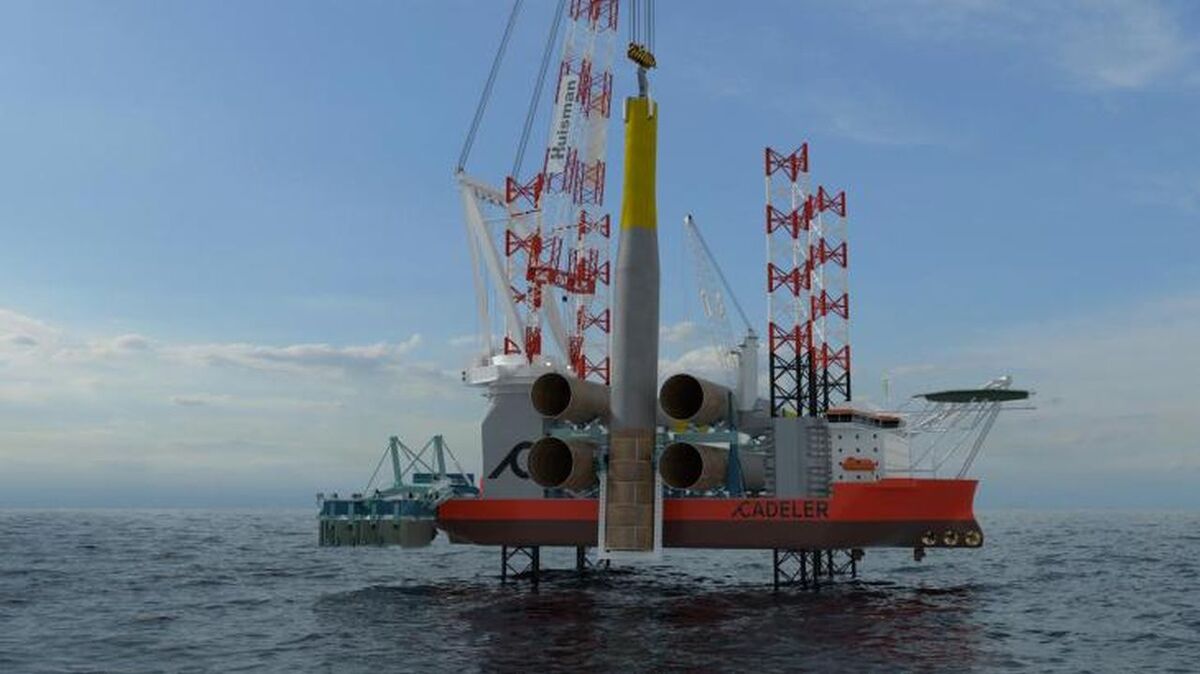

Suite of monopile installation equipment selected for Cadeler’s A-class

Contracts have been awarded for the design and construction of cranes and related foundation installation equipment for Cadeler’s A-class installation vessel, Wind Ally

Shipbuilder COSCO has awarded a contract to Huisman for a leg-encircling crane and a pedestal-mounted crane for the newbuild. A second has also been awarded to Huisman by the vessel owner for an upending frame and monopile storage system.

The leg-encircling crane will have a capacity of 3,000 tonnes and the pedestal-mounted crane will have a capacity of 40 tonnes.

Once in operation, the vessel will use the leg-encircling crane to install some of the largest foundations in the offshore wind industry.

Delivering the complete monopile storage and upending system, monopile gripper, and main and auxiliary cranes for the vessel will allow for smooth integration and interface alignment, reducing risk in the overall project.

The monopile storage system is designed to maximise monopile storage on the vessel, allowing Cadeler to transport up to five monopiles, each of up to 12.5 m diameter, in one trip. It will have adjustable storage cradles that accommodate monopiles with different diameters and will be height-adjustable.

The upending frame will support monopiles ranging from 80 m to 120 m in length, with what Huisman described as “enhancements for safer and more efficient upending.” Key features will include a crane automation mode that helps maintain the monopile’s position and retainers that secure the monopile during upending.

All of the equipment will be built at Huisman’s production facility in Zhangzhou, China.

Sign up for Riviera’s series of technical and operational webinars and conferences:

- Register to attend by visiting our events page.

- Watch recordings from all of our webinars in the webinar library.

Related to this Story

Events

Reefer container market outlook: Trade disruption, demand shifts & the role of technology

Asia Maritime & Offshore Webinar Week 2025

Marine Lubricants Webinar Week 2025

CO2 Shipping & Terminals Conference 2025

© 2024 Riviera Maritime Media Ltd.