Business Sectors

Events

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

Contents

Register to read more articles.

Oldest FSRU delivers decade-long uninterrupted regasification service

Operating since 2012 off Jakarta, FSRU Nusantara Regas Satu has completed over 425 cargo transfers and 50 million-m³ send-out without a single dry-dock

Known as one of the longest serving LNG vessels of its type, the FSRU Nusantara Regas Satu was originally built as LNG carrier Khannur at Moss, Norway, in 1977. The vessel entered service when LNG technology was in its relative infancy and pre-dated the IGC Code. At that time, MOSS containment systems dominated, and 125 000 m³ capacity represented the upper limit of cargo volume. The vessel’s design reflected the manual standards of the era, with control by analogue instrumentation and navigation by radar and sextant.

To put the timeline in context, in 1977, Jimmy Carter assumed the US presidency, the first Star Wars film debuted and the Apple II computer was released without a mouse — reminders that digital design and computer-aided drafting remained rare. At that time, analogue control systems and navigation by radar and sextant prevailed; environmental regulation was minimal under the 1954 OILPOL Convention, while the non-mandatory EGC Code of 1976, SOLAS 1960 and the yet-to-enter-force MARPOL annexes governed her initial regime.

After three decades of trading as an LNG carrier, Khannur completed over 120 cargo voyages from ADNOC’s Das Island to Japan, later loading from Ras Laffan and Trinidad for discharge in Spain and the United States. In 2011-2012, the vessel underwent conversion and a new name, Nusantara Regas Satu and became the fourth LNG‐to‐FSRU conversion globally and the second executed at that yard. Outfitted with an open-loop regas system and propane secondary heating, maximum send-out capacity is 500 MMcf/d.

Since redeployment 15 km north of Jakarta in 2012, Nusantara Regas Satu has facilitated over 425 cargo transfers through STS operations and delivered more than 50 million m³ of gas to Indonesia’s growing power market. In June 2025, cumulative send-out crossed the 50 million m³ threshold, and in December 2024 the vessel completed its 400th STS operation. Remarkably, the vessel has remained on location without gas freeing or dry-dock for the entire 13 years, a record believed to be unmatched among LNG vessels and FSRUs.

Maintaining structural integrity over nearly half a century demands rigorous corrosion management and fatigue monitoring. The vessel’s hull scantlings, greater than those of modern vessels, have provided a solid foundation, but ongoing challenges include abrasion of mooring lines and corrosion of mooring hardware. Owners and operators rely on bespoke inspections and retrofitted reinforcement to uphold safety margins in accordance with current classification society standards.

“Regulatory compliance has evolved substantially since the vessel’s launch in 1977”

Technological obsolescence poses further complexity. Legacy control systems and analogue gauges require specialist support amid a sea-change towards digital automation. Crew must be adept in manually driven processes while simultaneously accommodating incremental upgrades to meet present-day operational criteria. Integrating new instrumentation without full system overhauls has entailed phased installations and custom interface solutions.

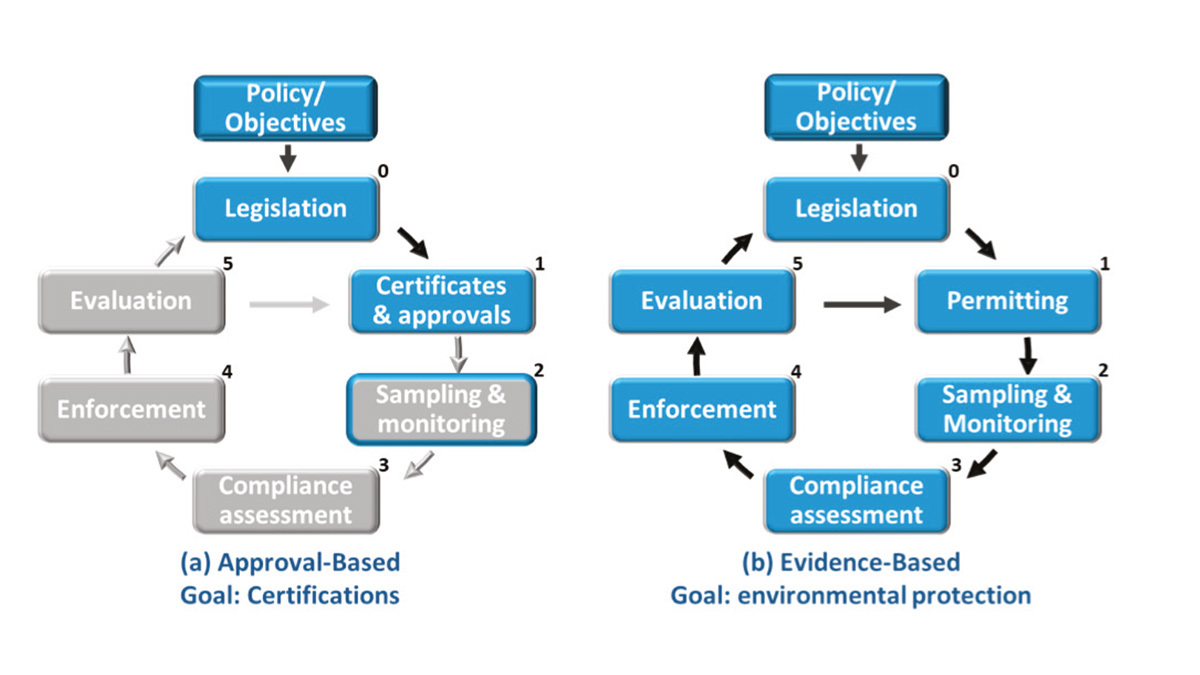

Regulatory compliance has evolved substantially since the vessel’s launch in 1977. Originally unregulated for emissions, sewage or ballast water, the unit now operates under stringent Marpol annexes and environmental frameworks that did not exist at its construction. Continuous engagement with Indonesian authorities and charterers ensures adherence to safety and environmental requirements, demanding transparent reporting and inspections under dual-class certification.

Operational efficiency cannot match that of purpose-built modern FSRUs; boil-off gas rates stand at 0.25% and operating expenditure is comparatively high. Yet, through tight schedule management and preventative maintenance during limited annual work windows, the vessel maintains availability targets. Crew rotations are aligned with maintenance cycles to minimise downtime while preserving specialist knowledge of the vessel’s unique systems.

Supply chain constraints for vintage systems present ongoing hurdles. Spare-part procurement often necessitates bespoke manufacturing or cannibalisation from sister vessels, two of which — Hilli and Gimi — were converted to FLNG and remain operational. This scarcity demands strategic planning, bulk ordering and elevated inventory levels to pre-empt failures. Environmental stewardship is addressed through continuous monitoring for leaks and emissions, supported by periodic upgrades to seals and valves to reduce the unit’s footprint.

“Crews must master systems dating from the 1970s while complying with contemporary LNG safety standards”

Human resource management balances legacy expertise with modern training. Crews must master systems dating from the 1970s while complying with contemporary LNG safety standards. Operator training programmes combine classroom instruction with onboard drills, fostering proficiency in both historic and modern procedures to maintain uninterrupted service.

A key element in the longevity is the mindset of the operator, Equinox Ship Management. As its general manager, Andrew Clifton, commented: “50 years old? No problem!” to underscore the vessel’s operational resilience.

Ships of that era were constructed with robust scantlings, and this FSRU’s service life raises the question: will LNG carriers delivered in the twenty-first century match half-century durability under evolving technical and regulatory regimes?

Riviera’s LNG Shipping & Terminals Conference will be held in London on 21-22 October 2025. Use this link to register your interest and attend the event.

Related to this Story

Events

Maritime Regulations Webinar Week

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

© 2024 Riviera Maritime Media Ltd.