Business Sectors

Events

Offshore Wind Webinar Week

Contents

Register to read more articles.

Stolt Tankers boosts fleet efficiency with innovative cleaning

Stolt Tankers is doubling its use of proactive hull cleaning technology, significantly reducing fuel consumption and improving sustainability

Stolt Tankers is taking significant steps towards fleet efficiency and environmental sustainability by expanding its proactive hull cleaning initiative. After observing fuel savings exceeding 10% during initial trials, the chemical tanker operator is doubling the implementation of this innovative technology across its fleet.

In an effort to reduce the carbon intensity of its operations by 50% by 2030 compared with a 2008 baseline, Stolt Tankers is incorporating a range of advanced technologies. Among these, the proactive hull cleaning technology has proven to be a crucial component.

This system was initially piloted on Stolt Acer, along with five other vessels, yielding substantial fuel consumption reductions.

“We see proactive hull cleaning as a straightforward method to achieve rapid emissions reductions at a relatively low cost,” said Stolt Tankers energy and conservation manager Jose Gonzalez Celis. “By maintaining the hull in a consistently optimal condition, we can minimise drag and ensure better performance, thus avoiding overconsumption of fuel.”

This initiative is part of a broader strategy to address rising fuel expenses and new regulatory measures, such as the EU Emissions Trading System (EU ETS), which imposes higher costs for emissions.

Proactive hull cleaning also contributes to preventing the spread of invasive species between ports, protecting coastal ecosystems, and reducing the environmental impact of biocide and plastic residues from anti-fouling coatings.

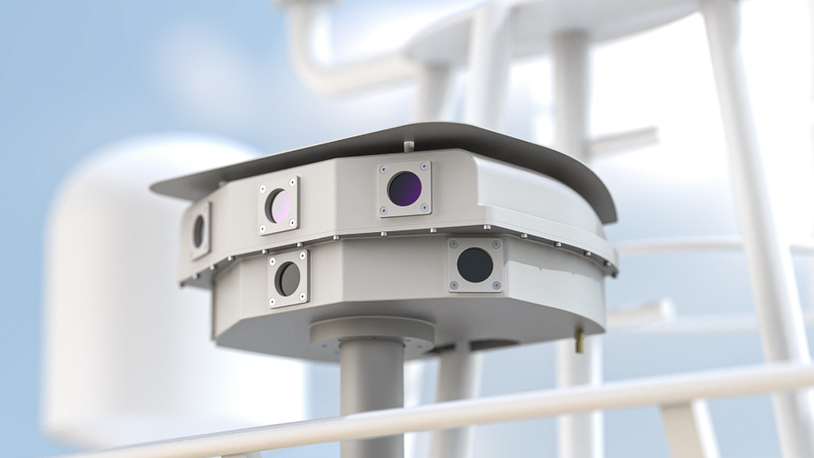

Stolt Tankers is expanding the use of this technology by doubling the number of units in its fleet to 20, enabling broader deployment of the upgraded cleaning system. The proactive approach contrasts with the traditional method of reactive cleaning, typically performed in port or drydock, which often results in increased costs, downtime and potential safety issues.

According to International Maritime Organization’s GloFouling research, even a thin layer of slime covering 50% of a hull’s surface can lead to a 25% increase in emissions, with the impact rising to 60% if barnacles are present. By implementing regular, proactive cleaning during transit, Stolt Tankers aims to avoid such inefficiencies and maintain optimal hull performance.

“Preventive hull biofouling management can significantly cut emissions, as supported by our real-life operational data,” added Mr Gonzalez Celis. “The technology’s proven effectiveness in reducing fuel consumption aligns with our commitment to sustainability and compliance with regulations such as the Carbon Intensity Indicator limits and the upcoming FuelEU Maritime regulation in 2025.”

Stolt Tankers is also exploring the use of graphene coatings on hulls and propellers, which are free of biocides and toxic chemicals, further enhancing fuel efficiency and reducing environmental impact. This is part of a suite of anti-pollution initiatives aimed at protecting marine ecosystems.

“Our successful implementation of proactive hull cleaning has demonstrated its value in improving the energy efficiency of our fleet,” noted Mr Gonzalez Celis. “Wider adoption of this technology is a testament to Stolt Tankers’ policy of continuous improvement, combining innovative thinking, enabling technologies, and future fuels to optimise fleet safety, sustainability and operational efficiency.”

Explore all the decarbonisation options the Crude Tankers & Terminals Conference, Awards & Exhibition 2024 (22-23 October 2024). Register your interest here. Nominations for the Awards is open to all stakeholders.

Hull coatings and cleaning are part of the portfolio of optimisation options available to shipowners and operators. Register now to hear about the other options available during Vessel Optimisation Webinar Week (17-20 June 2024).

Related to this Story

Events

Offshore Wind Webinar Week

Maritime Decarbonisation, Europe: Conference, Awards & Exhibition 2025

Offshore Support Journal Conference, Americas 2025

© 2024 Riviera Maritime Media Ltd.