Business Sectors

Events

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

Contents

Register to read more articles.

Electric propulsion: powering the decarbonisation of close-to-shore shipping

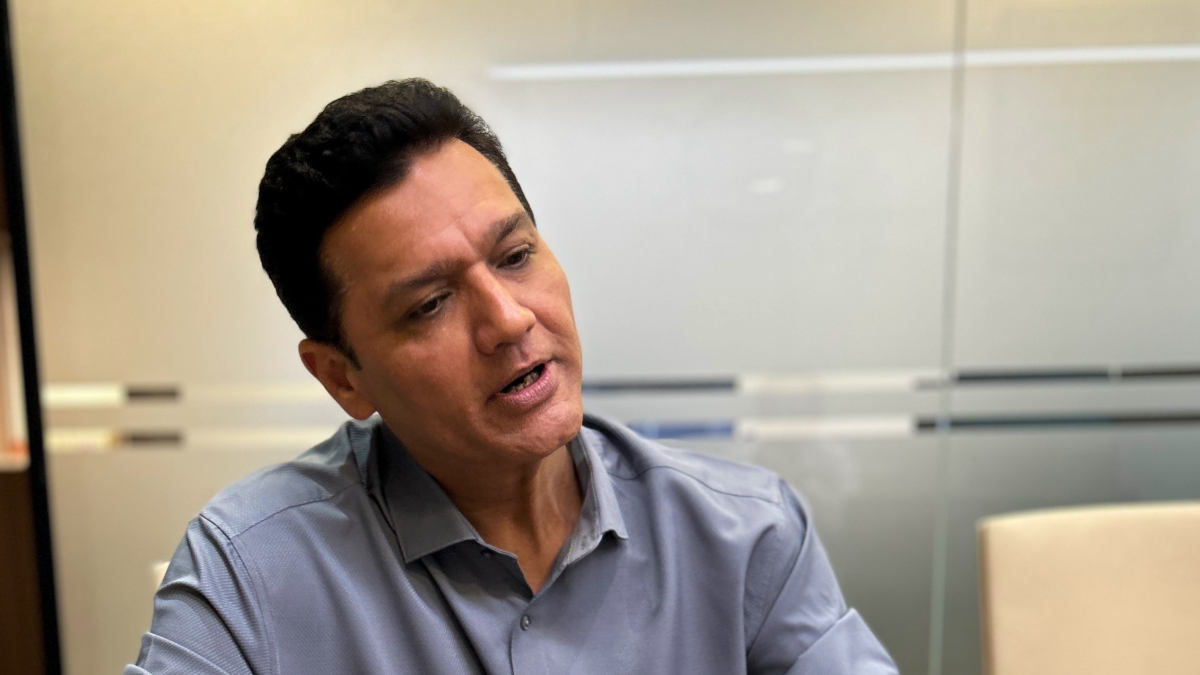

Electrifying coastal vessels can play a key role in lowering fuel consumption, improving efficiency and cutting CO2 emissions, writes ABB, Mobile e-Power, global sales manager, Luciano Santos

Close-to-shore shipping is the cornerstone of global trade. Domestic and coastal voyages account for 9.2% of global shipping emissions, with the entire marine industry responsible for about 3% of global CO2 output. As international and regional regulations tighten, through measures such as IMO’s Net-Zero Framework, operators face rising operational costs and mounting pressure to decarbonise. Innovations in electric propulsion are set to play a key role in improving operational efficiency and reliability, resulting in reducing marine emissions; by integrating new solutions, operators can significantly lower fuel consumption and future-proof their fleets.

The case for electrification

Electrification for close-to-shore maritime operations is no longer a distant goal. Near-shore and predictable operations offer ideal conditions for deploying electric propulsion systems without compromising on performance or range. Segments such as short-route ferries, harbour craft, and inland waterway vessels represent significant potential for transition, and compact systems are ideal for these vessels where stop-and-go operations are common. Solutions, which include marine motors, inverters, and batteries, may be hybrid or fully electric and can be integrated into existing vessels or newbuilds.

“The low-noise, low-vibration of the electric drivetrains make these solutions especially effective for domestic operations”

Fully electric systems rely solely on a battery energy storage system to power the vessel for the entire route, and this is well suited to short-distance shipping. Then, the low-noise, low-vibration of the electric drivetrains make these solutions especially effective for domestic operations, including on rivers, lakes, and ferry routes. When incorporated into newbuilds, electric propulsion systems require lower space requirements and maintenance costs and benefit from increased manoeuvrability. Estimates of the conversion efficiency from input energy to propulsive power range to as high as 90% and 98%.

ABB has delivered a fully integrated electric propulsion system for the first all-electric ‘Maid of the Mist’ tour ferries, allowing passengers to experience Niagara Falls completely free of engine noise, fumes, and emissions. These zero-emission ferries demonstrate the benefits of fully electric propulsion for small and mid-sized passenger vessels, enabling sustainable operation with maximum reliability.

Adapting fleets with hybrid and retrofit solutions

Hybrid and retrofit solutions are becoming essential as diverse vessel types, from ferries to harbour tugs and coastal supply ships, each require purpose-built approaches to meet operational and environmental demands. The main benefit of hybrid systems is their ease of adaptation to new fuels, as upgrading requires replacing only the generators rather than the entire propulsion system.

Modular system designs now allow seamless integration with existing propulsion setups, enabling smooth transitions that preserve power performance and optimise onboard space across a wide range of configurations. By adopting retrofit solutions, operators can reduce downtime, extend vessel lifespans, and achieve reliable, lower-emission operations without compromising service continuity.

To this end, ABB will supply the propulsion systems to Scotland’s Caledonian Maritime Assets Ltd for seven all-electric ferries between late 2027 and early 2029. The 50-m ferries will serve nine routes in the Clyde and Hebrides region on Scotland’s west coast. Integrated with the AXME Marine Motor, and with wall-mounted HES880 Mobile Inverters, the comprehensive solution combines high power density and light weight in a small footprint.

Meeting regulatory pressure

Navigating increasingly stringent maritime regulations has become a defining challenge for operators across Europe. To align with IMO decarbonisation targets, the Energy Efficiency Design Index was established to ensure that all new vessels meet a minimum standard of energy efficiency per capacity mile, with the different specificities for ship segments taken into consideration. Emission Control Areas in the Baltic, North Sea, and Mediterranean now mandate cleaner fuels to achieve cuts in nitrous-oxide emissions, which have increased in the EU by 10% from 2015 to 2023, with an 8% increase specifically in the Mediterranean. Regulatory frameworks such as FuelEU Maritime are driving up operating costs for any vessel still reliant on fossil fuels, requiring zero-emission power at berth from 2030/2035, and supporting flexible compliance to drive an 80% reduction in emissions by 2050.

“Crews praise its exceptional manoeuvrability, rapid response and instant electric power”

Smaller vessels, including tugboats, ferries, service craft, and fishing fleets, are experiencing the steepest rise in compliance and fuel-related costs. Replacing diesel engines with all-electric systems that comply with tightening port and maritime regulations is a practical pathway for small and mid-sized vessels to meet regulatory requirements and reduce operating costs.

A great example is the all-electric Zeetug30 tugboat, operating daily on harbour duties in the Port of Istanbul. Crews praise its exceptional manoeuvrability, rapid response and instant electric power, even in the confined spaces of the shipyard area. To achieve the Zeetug’s 30-tonne bollard pull within a confined space, ABB adapted its robust technology from heavy-duty mining applications, supplying 14 compact, liquid-cooled HES880 Mobile Drives. These drives delivered 925 kW of rugged, IP67-rated propulsion power. Zeetug30 delivers significant environmental and cost benefits, saving up to 210 tonnes of CO2 and nine tonnes of NOx annually while reducing operating costs by up to 85% compared with diesel tugs. This craft demonstrates how small vessels can effectively adopt zero-emissions technology.

A practical moment for electric and hybrid adoption

In this rapidly evolving regulatory landscape, electrification is emerging not merely as a compliance measure, but as both a strategic advantage and a financial imperative for close-to-shore operators. Proven applications – from fully electric ferries to hybrid craft – show that compact electric propulsion can deliver measurable emissions reductions and improved vessel performance. Operators need to adopt flexible electric and hybrid solutions to advance close-to-shore shipping towards a low-carbon future and protect their assets against future regulation. This will ensure the industry remains sustainable and economically resilient for decades to come.

Riviera’s Maritime Hybrid, Electric & Hydrogen Fuel Cells Conference & Exhibition will be held in Bergen, Norway, on 21-23 October 2026. Use this link for more information and to register for the event.

Related to this Story

Events

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

© 2024 Riviera Maritime Media Ltd.