Business Sectors

Events

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

Contents

Register to read more articles.

Decarbonizing Offshore Support Vessels (OSVs) and Platform Support Vessels (PSVs) with DC Power Grids and Energy Storage

For OSVs and PSVs with highly variable power demands, the operational advantages of DC-based diesel-electric propulsion (DEP) systems in combination with batteries or fuel cells are significant. These systems not only offer benefits in terms of fuel efficiency and emissions reduction but also provide a level of operational flexibility that can empower vessel operators.

DEP technology, with its increasing popularity driven by the focus on fuel efficiency and emissions reduction, is now a versatile solution for a wide array of ships. This includes PSVs, OSVs, drill rigs, research vessels, yachts, passenger car ferries, and cruise liners.

Various DEP systems are available on the market. While modern AC- and DC-based solutions both possess inherent advantages, the size and operating profile of the vessel will determine which type of electrical distribution is optimal.

Studies and operational experience have shown that in medium-voltage (MV) applications, AC power systems can be a better option than DC due to lower electrical losses. However, for vessels under 10 megawatts (MWs) with highly variable loads, low-voltage DC (LVDC) power distribution in combination with energy storage offers several advantages, including higher fuel economy, weight and footprint savings, and opportunities for intelligent monitoring and energy optimization.

AC vs. DC Power Distribution

Many marine vessel operators are familiar with AC-based power distribution, which has been used with success for decades. However, one inherent disadvantage of older AC systems is that all the diesel generators in the power plant must be kept running at the same fixed speed to maintain constant frequency and voltage. This is not ideal for vessels that only require full power during a small portion of operation. A typical PSV, for example, only requires full power around 25% of the time. For the rest of its operation, the power requirement is low.

During these periods of low power demand, diesel engines are partially loaded, and the engine temperature is not high enough to burn all available fuel, leading to reduced fuel efficiency and increased emissions. This is otherwise referred to as “wet stacking,” and it can significantly impact the diesel engine’s performance and cause many conditions that reduce its operational life.

Modern DEP systems address these limitations. In the case of newer AC-based designs, power plants are operated with a closed bus tie, and a power management system automatically starts and stops generators to minimize fuel consumption.

In DC-based systems, the frequency of the generators is decoupled from the electrical consumers, permitting the use of several variable-speed diesel gensets. These gensets can adapt their speed to match vessel power demands, resulting in higher efficiency at low loads. This efficiency not only ensures better fuel economy but also a lower emissions profile.

In addition, the variable-speed engines enable optimization of exhaust temperatures during low-load operations, resulting in up to an 83% reduction in NOx emissions compared to a conventional AC DEP vessel.

Other notable advantages of DC-based power distribution include:

• Space and weight savings - DC systems eliminate the need for transformers. All consumers can be connected directly to the switchboard, leading to as much as 30% space savings in the mechanical footprint of the power plant versus an AC-based system.

• Ability to recapture energy from braking - During dynamic positioning (DP) operation, cranes or other electrical equipment can send braking power back to support the hotel load or other consumers, further improving fuel efficiency.

• Ease of integration with battery energy storage - With DC grids, power produced from batteries or fuel cells does not have to be converted, simplifying installation and commissioning.

• Intelligent monitoring and control – Many small energy consumers on ships, such as pumps, fans, etc. rely on fixed-frequency power. In DC grids, these consumers can be monitored and individually controlled to optimize efficiency and further reduce vessel fuel consumption.

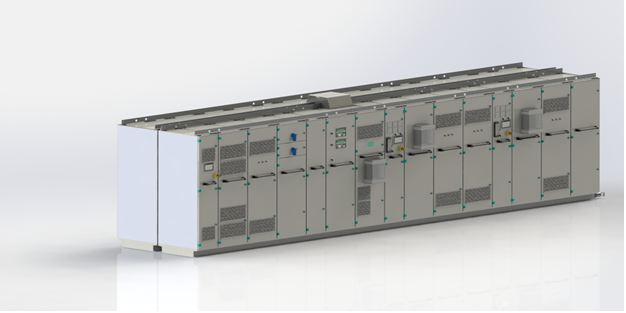

BlueDrive PlusC ™: Siemens Energy’s LVDC Power and Propulsion System

Siemens Energy has been a pioneer in the development of both LV and MV DEP systems. Today, more than 100 vessels worldwide utilize the company’s LVDC BlueDrive PlusC power and propulsion system.

BlueDrive PlusC is based on fully integrated power distribution. The main switchboard utilizes in/out AC voltage and supplies clean power to other switchboards. Engine speed is controlled to optimize fuel consumption and reduce load-deviation issues.

BlueDrive PlusC is ideal for ships with variable power profiles and demanding operational requirements. During vessel DP operation, production and even spinning reserve can be realized with limited consumption, emission, and maintenance costs. To lower fuel consumption further, the system makes it possible to shift load between the port and starboard parts of the system.

Depending on the vessel’s operation profile, Blue Drive PlusC can reduce fuel consumption by 20-30% versus conventional diesel engines. Some customers have also reported up to 20% lower maintenance costs on their diesel gensets. Key features of the BlueDrive PlusC system include:

• Power and energy sources integrated with loads

• Variable speed AC generators optimized for fuel efficiency

• Ultrafast-acting, solid-state bus tie allows for cross-connected operations even in restricted maneuvering/ DP conditions

• Integrated switchboards incorporate all inverters

• Propulsion transformers are not required

• Energy storage systems can be incorporated directly onto the main bus

• The power/energy management system optimally ensures high reliability

BlueDrive PlusC improves redundancy through thruster feeds from two switchboards with their own supply to all relevant auxiliary systems. This is particularly important for DP vessels, as it improves the environmental regularity number (ERN). Because drives and the main switchboard are in one compact unit, Siemens Energy can run comprehensive integration tests before delivery to the yard. The combination of less equipment installed, and early testing reduces build time and costs.

Incorporating Battery Energy Storage for Hybrid Operation

In recent years, Siemens Energy has seen a growing number of its customers opt for LVDC technology combined with the company’s BlueVault battery energy storage solution. This hybrid configuration provides several added benefits, including:

• Lower fuel consumption: Battery power can reduce engine running time and provide further fuel and emissions savings.

• Improved dynamic operation: Diesel generators are slow to handle large, abrupt load changes. Batteries, on the other hand, can provide close to instantaneous power for low response capability in critical situations and reduce rapid speed changes during normal operation. Regenerative energy from cranes or draw works can also be captured and stored, reducing the need to use braking resistors.

• Increased reliability: Battery energy storage enables operators to potentially create new redundancy schemes. Introducing batteries can remove the need for load shedding, as the stored energy can bridge the gap between one engine failing and another starting up. Furthermore, operators may be able to reduce the number of auxiliary generators on the vessel by using batteries for backup.

To date, BlueVault has been installed on more than 60 hybrid and all-electric vessels around the world. The battery technology was specifically designed for offshore and maritime applications and incorporates several unique safety features to mitigate the risk of failure and thermal runaway. Among these is a freshwater cooling system that cools battery modules three-dimensionally. The water acts as a thermal barrier and protects against an internal fault spreading and causing thermal runaway, irrespective of whether the coolant circulates.

Other unique safety features include arc and thermal runaway propagation protection. In the event of thermal runaway, the event is designed to be isolated and contained to the cell level. Any gases produced from heating are drawn via an external suppressor fan and ducted from the module through the cubicle to a safe area, thus ensuring that only one module is compromised.

A digital surveillance system continuously monitors the voltage and temperature of individual battery cells to provide transparency regarding state–of–health (SOH) and state–of–charge (SOC). Depth–of–discharge (DOD) is also monitored to help predict the solution’s lifetime estimation. Each battery module contains roughly 90 monitoring points. For example, in a 1 MWh battery system, as many as 15,000 data points are collected and transferred to a data repository for condition and performance monitoring and analysis.

For LVDC systems, batteries are connected via Energy Storage Feeders or a Controlled Energy Storage (CES) bi-directional DC/DC converter.

Siemens Energy is also currently working with shipbuilders to incorporate hydrogen fuel cells in hybrid configurations.

Conclusion: Extending DEP Technology to Larger Vessels

For OSVs and PSVs with highly variable power demands, DEP systems represent a sustainable, reliable, and cost-effective alternative to fossil-fired mechanical drives. In many cases, the lifecycle cost of DEP technology is already approaching parity with conventional diesel systems. As fuel costs and carbon taxes increase, they will become even more attractive.

DC-based power distribution systems have only been commercialized for vessels with lower power requirements, typically under 10 MWs. However, Siemens Energy is currently developing a medium-voltage BlueDrive PlusC variant to meet the growing demand for electrifying larger ships.

The company is also applying parts of DEP technology to support decarbonizing cargo carriers and LNG vessels. Ocean Green is a novel concept Siemens Energy developed in collaboration with DNV, Fearnleys, and Moss Maritime that utilizes a combined cycle power and propulsion plant integrated with BlueVault batteries².

Other solutions that Siemens Energy is applying to help its marine customers reduce emissions and electrify their fleets include electric podded propulsion systems and shaft generators for power take-in and take-off applications.

Related to this Story

Events

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

© 2024 Riviera Maritime Media Ltd.