Business Sectors

Events

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

Contents

Auckland’s first plug-in hybrid-electric fast ferry set to enter service

Auckland Transport’s hybrid fast ferry ‘surpassed expectations’ at sea trials, and is expected to reduce carbon emissions by 750,000 kg per year

In a major milestone for Auckland, New Zealand’s public transport network, the city’s first plug-in hybrid-electric fast ferry has performed ‘exceptionally’ on sea trials and will soon enter service on the Auckland to Devonport commuter route.

The vessel achieved a top speed of 36 knots on all-electric mode, with the performance of the electric propulsion and onboard systems “consistently meeting and surpassing expectations”, said a statement from Incat Crowther.

The new vessel will contribute to Auckland Transport’s mission to modernise and decarbonise the city’s ferry fleet. The vessel is expected to reduce carbon emissions by 750,000 kg per year.

Designed by digital shipbuilder Incat Crowther, built by Q-West Boat Builders with systems integration by Hamilton Jet, the 32-m vessel is the first of two electric-hybrid fast ferries that will be operated by Fullers360 for Auckland Transport.

Capable of transporting up to 299 passengers and 20 bicycles at speeds of up to 28 knots, the new vessel has been designed for “safe, comfortable, and highly reliable commercial rapid transit ferry services”, said Incat Crowther. The passenger experience has been enhanced by including a range of seating options – including tables and USB ports for those that need to work on their commute, fold-up luggage compartments and floor-to-ceiling windows.

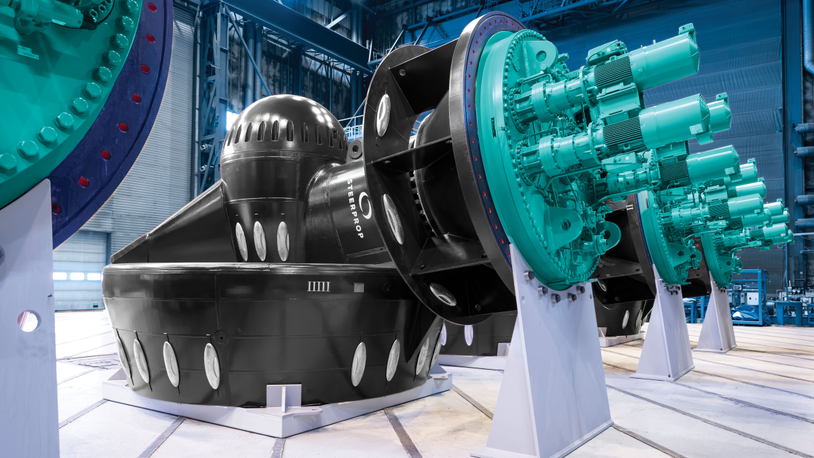

The vessel’s drivetrain includes four Danfoss EM-PMI540-T4000 electric motors, Hamilton HTX42 water jets, and hybrid-electric systems. Incat Crowther has utilised cutting-edge digital shipbuilding technology in designing the support systems for the electric propulsion system.

This includes liquid cooling systems featuring pumps and heat exchangers for e-motors, converters, inverters and switchboards, and chillers for batteries. The design also features electrical equipment and a cable route arrangement to minimise electromagnetic interference, fire suppression systems, and battery room ventilation systems. Weight control for such expansive systems has been critical, with each item weighed and tracked throughout construction.

The vessel’s drivetrain features the ability to employ a pair of range-extending generators that can be used in conjunction with the battery bank. This technology supports electrification and reduces emissions while delivering on timetable and range requirements. The vessels are also future-proofed and can be refitted to operate on hydrogen fuel for increased range in the future.

Fullers360 head of innovations and asset development Liam Dowling said, “The flexibility, adaptability and spirit of partnership that’s gone through this project has been key to making Auckland’s first plug-in electric-hybrid ferry a reality.”

Incat Crowther technical manager Dan Mace said, “This new vessel will offer Aucklanders a world-class, low-emissions travel experience. Incat Crowther’s expertise in conceptualising the vessel design to ensure it is tailored for Auckland Transport’s operational requirements, combined with the application of the latest digital shipbuilding technology, was critical to the successful delivery of this project. This tailored design approach also ensured the vessel’s electric drive system was accurately and reliably integrated from the outset. Embedding digital shipbuilding processes throughout the project will also provide a range of benefits to Auckland Transport and Fullers360 over the long term – including lower maintenance costs and improved operational outcomes through streamlined training for staff.”

Sign up for Riviera’s series of technical and operational webinars and conferences:

- Register to attend by visiting our events page.

- Watch recordings from all of our webinars in the webinar library.

Related to this Story

Events

Maritime Regulations Webinar Week

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

© 2024 Riviera Maritime Media Ltd.