Business Sectors

Events

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

Contents

Propulsion selected for Østensjø’s offshore tug newbuild

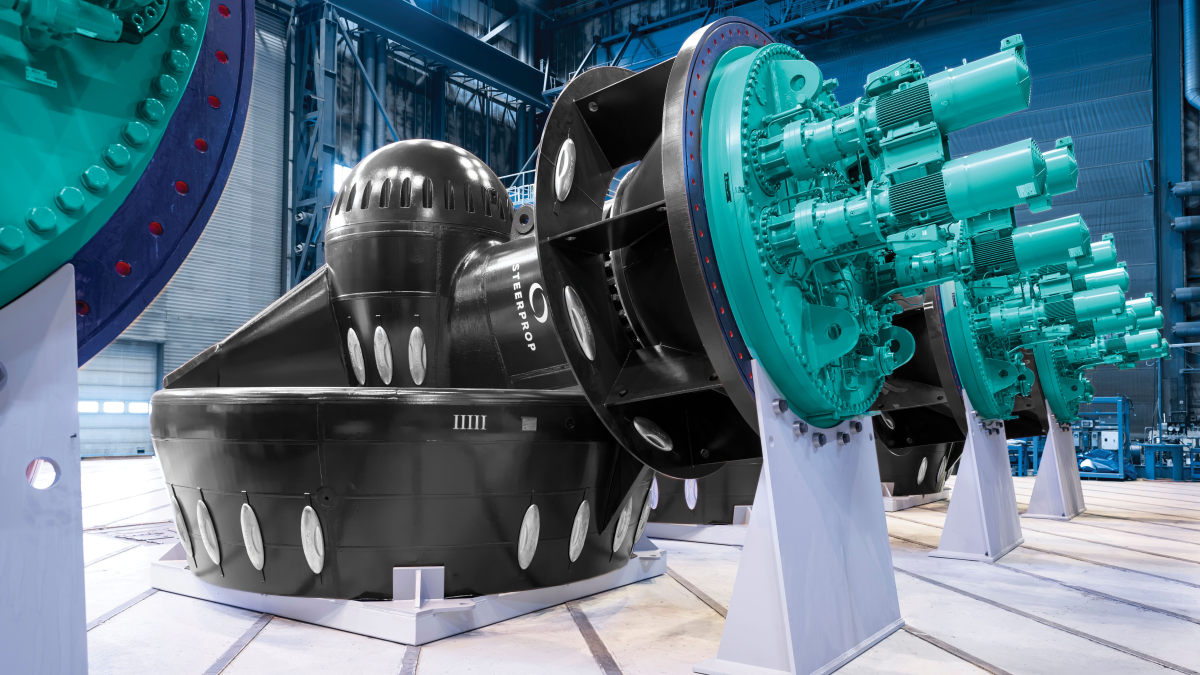

Two azimuth thrusters will be delivered to a Spanish shipyard to be combined with Caterpillar main engines on a methanol-ready, diesel-electric tug being built for Østensjø Rederi

Gondan Shipbuilders has selected propulsion units for a methanol-ready, diesel-electric tug it is building in Spain for Østensjø Rederi to support offshore operations and ship-handling in Norway.

This 50-m vessel will be built to a Skipsteknisk ST-933 design with hybrid propulsion, DP2-class dynamic positioning, Caterpillar engines and generator sets and Steerprop propulsors.

Gondan selected Steerprop’s SP 50 WD dual-end, ducted propulsors, each able to be driven by a diesel engine and an electric motor for this vessel.

This combination will generate around 150 tonnes of bollard pull and enable the tug to remain in position in all sea and weather conditions.

Steerprop said its ducted propulsors are suited to hybrid propulsion as they can connect to two power sources and have a mechanical propeller drive and a fixed-pitch propeller.

On Østensjø’s new tug, most operations will be undertaken using the electric motor, while the diesel engines will provide additional power when a higher bollard pull is required.

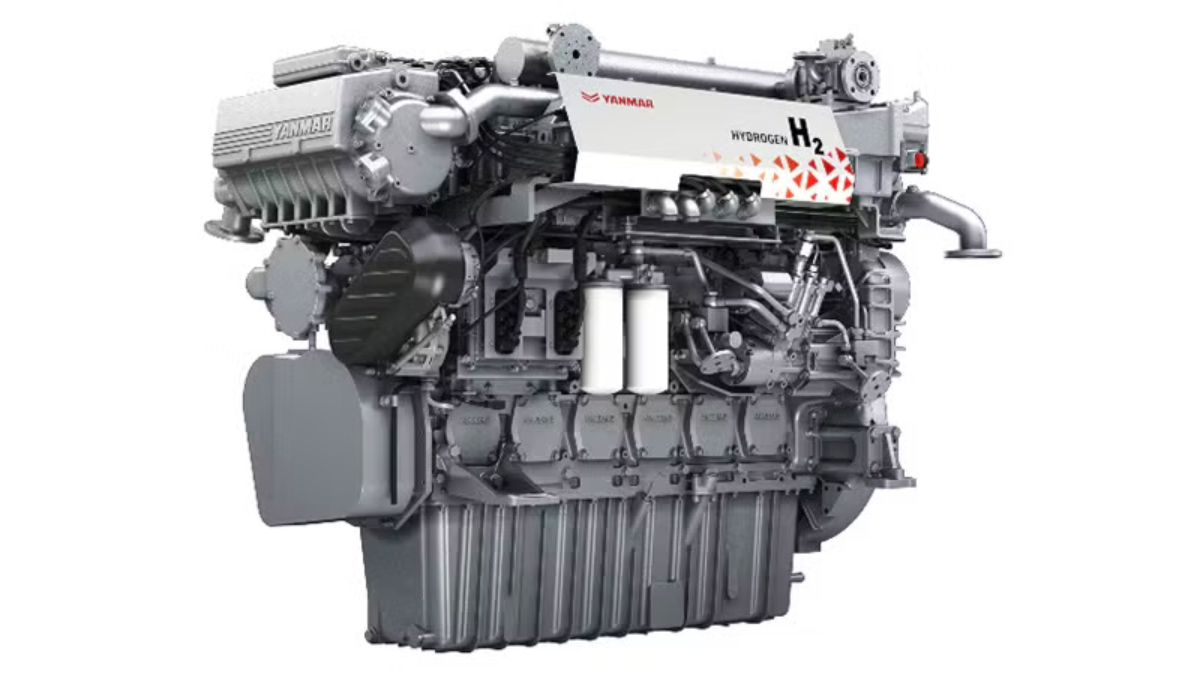

Zeppelin Power Norway will supply two 16-cylinder Cat 3516E engines with six sequential turbochargers to boost power, and selective catalytic reduction aftertreatment systems for NOx extraction from the exhaust.

These four-stroke, high-speed engines will be prepared to combust biodiesel and for future conversion to methanol.

The tug’s power systems will include two double-insulated Cat 3512E variable speed gensets, a Cat 9.3 harbour generator and a Cat C4.4E emergency generator.

“The newbuild represents a major step in further strengthening our offshore towage fleet and will be our flagship in the tug segment,” said Østensjø chief executive Kristian Helland Vea.

“It should achieve the highest possible efficiency through a hybrid propulsion configuration tailored to its operating profile,” he said.

According to Steerprop, ducted propulsors are deployed when efficiency, thrust at low speeds and manoeuvrability are operational priorities.

Steerprop director of sales and project management Juho Rekola said the Finnish company worked with the shipowner from an early stage to design the propulsion solution.

This offshore tug will have a beam of 17 m, accommodation for 14 and is scheduled to be delivered in Q1 2028.

Gondan has also contracted Schottel to supply two azimuth thrusters for a new vessel it is building for the UK’s Northern Lighthouse Board (NLB) to maintain and service lighthouses, buoys and other marine aids to navigation.

Pole Star will have two rudderpropellers of type SRP 460 LE and two STT 2 transverse thrusters to support its DP capabilities and provide propulsion redundancy.

In Australia, Schottel has overhauled two SRP 200 rudderpropellers for Bhagwan Marine at the Fremantle Foundry & Engineering Co workshop during the buoy tender vessel’s scheduled drydocking in Dampier.

Azimuth thruster trials

Aquamaster has completed commercial trials of its AQM-Pro 360-degree fully rotatable azimuth thrusters on a tugboat, demonstrating it is ready for installation on new tugs.

With two of these thrusters, this tug is capable of up to 85 tonnes of bollard pull and has high manoeuvrability in tight harbour environments for ship handling and docking.

Aquamaster claims AQM-Pro “increases tug operational capacity and versatility across multiple harbour activities, with enhanced energy efficiency from more effective thrust vectoring.

It said these thrusters “reduce turnaround times in ship berthing/unberthing operations and set new power benchmarks for rotatable thruster tugs.”

The 28th International Tug & Salvage Convention, Exhibition & Awards will be held in Gothenburg, Sweden, in association with Caterpillar, 19-21 May 2026. Use this link for more details of this industry event and the associated social and networking opportunities.

Related to this Story

Events

Maritime Regulations Webinar Week

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

© 2024 Riviera Maritime Media Ltd.