Business Sectors

Events

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

Contents

Fleet of ice-breaking carriers propel Russia’s Arctic LNG ambitions

With newbuilding programmes in Russia and South Korea, Sovcomflot will soon have an impressive fleet of ice-breaking LNG carriers to transport cargoes from Russian Arctic LNG export projects

Russian President Vladmir Putin has ambitious plans for development of the Arctic through 2035, underpinned by the country’s vast gas resources in the region, the opening of the Northern Sea Route (NSR) to commercial shipping and the introduction of a fleet of new ice-breaking LNG carriers.

Using the NSR allows LNG produced in the Russian Arctic to be delivered to Asian buyers in 15 days via the Bering Strait, lowering transportation costs and cutting the transit time in half from the traditional Suez Canal route.

In May, Russian shipowner Sovcomflot’s ice-class ARC7 LNG carrier Christophe de Margerie completed an eastbound passage across the ice-infested NSR to China with a cargo of LNG from Novatek’s Yamal LNG project. The passage from the Port of Sabetta to Cape Dezhnev took the vessel 12 days to complete, during which the LNG carrier covered 2,563 nautical miles (4,750 km).

It was the first time a large-capacity LNG carrier had crossed the route eastbound as early as May, when ice conditions remain challenging. Traditionally, the navigation in this sector commences only in July.

Commenting on the voyage, SCF president and chief executive Igor Tonkovidov, said: “Even in the challenging ice conditions encountered during this time of the year, choosing the NSR allows for a significant reduction in the length of a voyage delivering LNG to APAC ports compared with using the Suez Canal. A shorter voyage both allows [us] to optimise logistics and reduce the carbon footprint of the shipping.”

Located on the Yamal Peninsula, Yamal LNG – with a nameplate capacity of 17.4 mta – is one of several LNG export projects in the region. About 70 km across Ob Bay from Yamal LNG, Novatek is developing the US$21.3Bn Arctic LNG 2 project, with a capacity of 19.8 mta, with first commercial production in 2023. A smaller project, Ob LNG, is being developed with a capacity of about 4.8 mta in the central Yamal Peninsula. It is also expected to begin commercial operations in 2023.

Investing in ice-class tonnage

It’s been an intoxicating time for Sovcomflot (SCF), which recently listed 17.2% of the company on the Russian Stock Exchange, raising US$550M in an IPO.

“The privatisation of Sovcomflot will enable the company to actively expand in the key areas of sea energy transportation and seismic exploration,” said Russian Direct Investment Fund chief executive Kirill Dmitriev. “It will also help serve existing Russian and international energy projects more efficiently and participate in the development of new routes, including through the Northern Sea Route and the Arctic zone of the Russian Federation.”

To transport the vast quantities of LNG that will be produced in the Arctic, SCF is investing in ice-class tonnage to support Yamal LNG and Novatek’s Arctic LNG 2 project. Working with operator Arctic LNG 2, SCF has concluded 30-year time charter agreements for three new icebreaking LNG carriers. To be built by South Korea’s Daewoo Shipbuilding & Marine Engineering (DSME) to Russian Maritime Register and Bureau Veritas class, these Yamalmax-class vessels will each have an overall length of 299.9 m, beam of 47.4 m, open water speed of 19.5 knots, with a capacity of 172,410 m2. The design was jointly developed by Aker Arctic, DSME and Novatek.

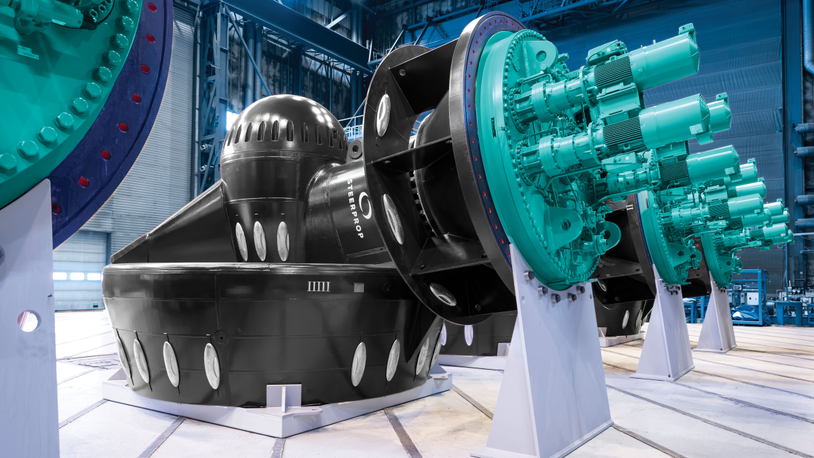

Propulsion for each of the new LNG carriers will comprise three ABB Azipods with a total capacity of 51 MW – comparable to that of the nuclear-powered icebreaker 50 Let Pobedy, which has propulsive power of 55 MW.

Flying the Russian flag and crewed by Russian seafarers, the three new LNG carriers, Hulls 2514-2516, will be delivered from February 2023 to July 2023.

The time charter agreements over the 30-year charter period will generate US$4.2Bn, said Mr Tonkovidov, pushing SCF’s total contract backlog to about US$24Bn.

“A shorter voyage optimises logistics and reduces the carbon footprint”

With the latest order, SCF’s fleet of gas carriers will grow to 34 vessels – 15 in operation and 19 under construction.

Previously, 15 icebreaking LNG carriers for the Arctic LNG 2 project were ordered from Russia’s Zvezda Shipbuilding. SCF will own the lead vessel in the series and is a joint venture partner with Novatek in Smart LNG, the owner of the other 14 LNG vessels. South Korea’s Samsung Heavy Industries (SHI) is Zvezda’s technology partner. To be delivered between March 2023 and December 2025, these vessels, Hulls 041-055, will be the first ice-breaking LNG carriers ever built in Russia, and time chartered to Novatek.

Mark III containment technology

All 15 of ships being built by Zvezda will have GTT’s Mark III membrane containment technology. In October, Zvezda ordered tank designs from GTT for 10 LNG carriers, each of which will have an overall length of 300 m, beam of 48.8 m, depth of 26 m, with a capacity of 172,600 m3.

In July, GTT secured the order for the tank designs for the first five vessels in the series. This award was the first under a technical assistance and license agreement GTT signed with Zvezda, allowing the shipyard to construct the membrane technologies developed by the French company. A cryogenic membrane technology, Mark III technology has a distinctive design featuring a combination of a stainless steel membrane and polyurethane foam insulation.

GTT’s Mark III technology has received the General Approval for Ship Application (GASA) from the Russian Maritime Register of Shipping (RS).

Under the GASA procedure, RS, in close cooperation with GTT, reviewed over 70 documents covering membrane tanks design, construction, and service aspects against applicable RS Rules and the IGC Code requirements. RS reviewed the basic methodology for Mark III cargo containment system strength calculations and sloshing loads estimations, as well as the testing and repair procedures for structural elements.

RS says the GASA ensures a smooth transition from conceptual LNG ship design to detailed design and class approval.

LNG FSU transhipment hubs

To further lower transportation costs and speed deliveries of LNG cargoes via the NSR to Europe and Asia, Novatek has signed contracts worth US$748M with DSME to construct two 360,000-m3 LNG barges that will serve as floating storage units (FSU) and transhipment hubs for Russian LNG.

Delivery of the two FSUs is scheduled for H2 2022, and the shipbuilding contract contains options to construct two additional LNG FSUs.

Each LNG FSU would serve as a floating LNG storage terminal, receiving and storing cargoes transported by icebreaking Arc7-class LNG carriers from Russian LNG projects in the Arctic. Those cargoes would be offloaded to conventional LNG carriers for transhipment to Europe or Asia. One FSU would be moored in the Murmansk in north-western Russia in the Barents Sea and the other in Kamchatka, located in the Russian Far East, where the Pacific Ocean meets the Sea of Okhotsk.

Related to this Story

Events

Maritime Regulations Webinar Week

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

© 2024 Riviera Maritime Media Ltd.