Business Sectors

Events

Contents

Improve CII ratings using real-time gas data

Can using high-quality data support the transition from reactively reporting to proactively optimising processes on board?

In a presentation at the LNG Shipping & Terminals Conference in London in November 2023, Tunable business development manager Per Christian Johnsrud unveiled its innovative gas analyser technology, which could improve Carbon Intensity Indicator (CII) ratings using real-time gas data.

Founded in 2015, Tunable has developed a novel approach to gas analysis, centred around a programmable filter chip the size of a little finger nail, which forms the core of the technology. This filter enables the detection of various gases visible by infrared spectroscopy, offering shipowners a new level of insight into their vessel’s emissions profile.

Mr Johnsrud emphasised the pressing environmental concerns facing the shipping industry today, with new regulations such as CII and the EU Emissions Trading System (ETS) imposing significant challenges on shipowners. “Older LNG vessels in particular,” he said, “could potentially face challenges, maintaining licence to operate under these stringent regulations.”

The Tunable gas analyser system has already been adopted by more than 50 shipowners, with LNG vessel operators prominently featured on its reference list. This technology provides real-time, continuous measurement of gas composition, empowering shipowners to optimise their operations for improved engine efficiency and reduced emissions.

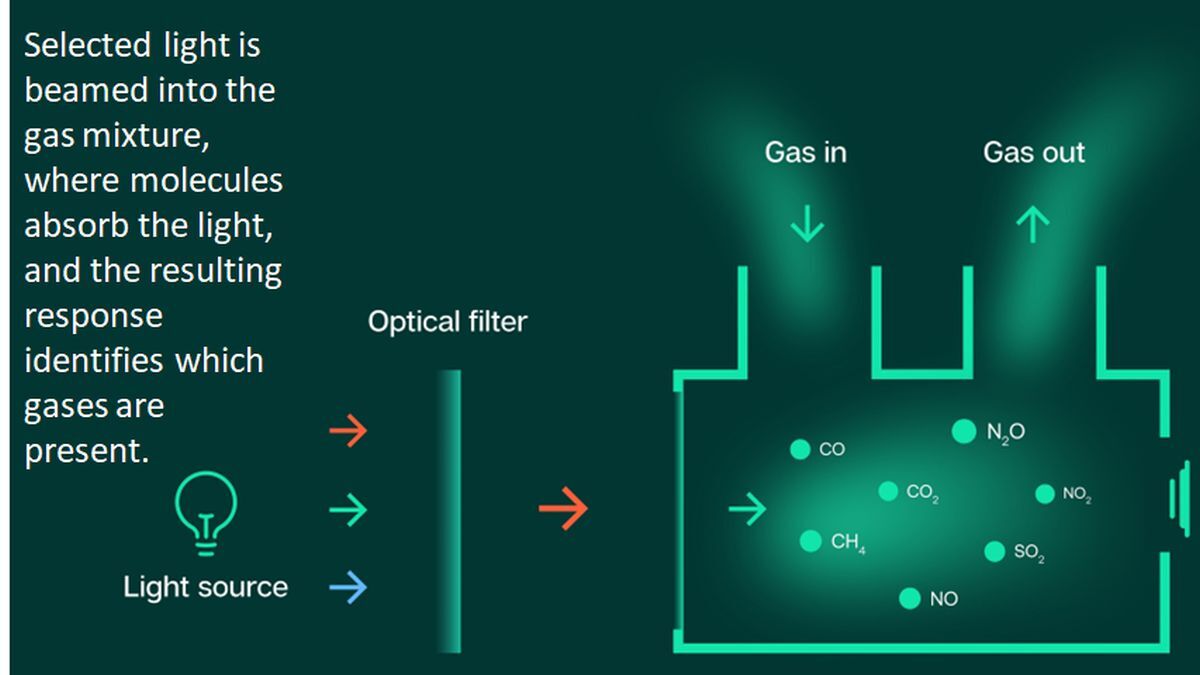

The Tunable gas analysis technology works by using infrared spectroscopy. There is a continuous gas sample taken from the gas stream. A black light (infrared) is beamed through the Tunable programmable filter, making it possible to measure many gases in real time.

The gas flows through the analyser while in real time, the filter changes the wavelength of the light beaming at the gas, and a gas detector measures the amount of light which has been absorbed.

The natural gas analyser is measuring all the hydrocarbons and nitrogen and calculates the Calorific value and the Metan number. The natural gas analyser is ATEX zone 1 certified to be used in hazardous environment. Typically, it is installed to take out a gas from the fuel gas line before it enters the engine or auxiliary/generator engines. The analyser is either located in the gas valve unit room or in the cargo compressor room. The emissions analyser measures greenhouse gases such as CO, CO2, NO, NO2 , SO2 and CH4 in one analyser without the need for a NO2 converter.

“Typically, the data is transmitted to the bridge for analysis and yields actionable insight for engine efficiency and can be provided into power management systems, engine control systems, and voyage optimisation and reporting systems. The connectivity ensures efficient communication with operators on land and enables diagnostics and software upgrades,” said Mr Johnsrud.

Key features of Tunable’s gas analyser technology include its robustness against vibration, critical for maritime applications, and its ability to measure multiple gases simultaneously with high accuracy. This capability is achieved through an innovative sampling probe and programmable filter chip, enabling rapid and reliable gas analysis without the need for calibration gases or complex maintenance procedures.

One of the most significant advantages highlighted by Mr Johnsrud is the ability of Tunable’s technology to provide shipowners with actionable insights into their vessel’s emissions profile. By combining gas analysis with artificial intelligence and machine learning, shipowners can optimise their operations in real time, leading to reduced fuel consumption and lower emissions.

The key is the relationship of nitrogen in LNG. Typically, said Mr Johnsrud, this is around 0.3% in LNG from the Middle East. “Until now,” he said, “there has been reliance on cumbersome boil-off gas tables.” But nitrogen volume boil off gas can vary between 5-10%, depending on voyage length, speed, weather, vessel condition, engine and more.

“Keeping track of nitrogen volume can improve CII by 5-10%. Which means the shipowner can extend the lifetime of the vessels by two to three years, without doing other costly actions, like speed reductions, non-optimal routeing and so on,” he said.

Tunable’s gas analyser technology offers transparency in gas quality, facilitating better communication between shipowners and charterers, noted Mr Johnsrud. This not only aids in negotiation processes but also allows shipowners to make more informed decisions when tendering for new contracts.

He concluded that Tunable’s gas analyser technology marks a significant step forward in the maritime industry’s efforts to address environmental challenges and improve operational efficiency.

Riviera Maritime Media’s LNG Shipping & Terminals Conference will be held in London, 12 November 2024, click here to register your interest in this industry-leading event

Related to this Story

Events

Offshore Support Journal Conference, Americas 2025

LNG Shipping & Terminals Conference 2025

Vessel Optimisation Webinar Week

© 2024 Riviera Maritime Media Ltd.