Business Sectors

Events

Contents

Register to read more articles.

Innovative Ultramax design featuring onboard ammonia cracking advances with 'increased force'

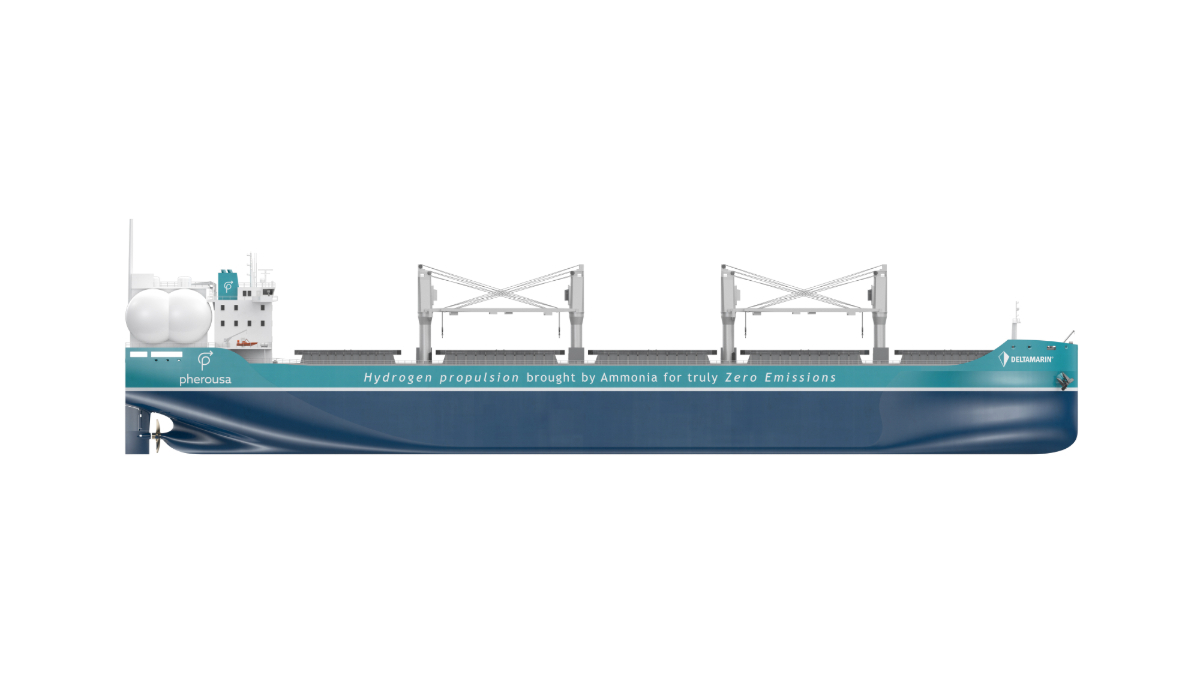

Norwegian technology company Pherousa is moving forward with its project to build a series of zero-emissions Ultramax bulk carriers, having secured approval in principle (AiP) for its onboard ammonia cracking technology

Last week, Pherousa disclosed that it received AiP certifications from both ABS and DNV. "The work on the series of Ultramax vessels continues with increased force after obtaining these AiPs," Pherousa chairman Hans Bredrup told Riviera. The company had previously outlined plans to construct six 64,000-dwt Ultramaxes through its subsidiary, Pherousa Shipping.

Mr Bredrup, who owns approximately 50% of Pherousa through Norwegian entity Cordia AS, clarified the project remains in the design phase. The AiP for the ammonia cracking technology was a necessary step to advance vessel design and move towards yard tendering. “We aim to have the vessels operational by 2030, coinciding with the IMO implementation timeline,” he added.

According to Pherousa, the AiPs validate the viability and safety of the company’s ammonia cracking technology, which, when integrated with PEM fuel cells and the fuel gas supply system (FGSS), enables fully electric propulsion.

Key partners involved in securing the two AiPs include ship designers Deltamarin, the flag state Marshall Islands, and Babcock International Group, which supplies the FGSS, as well as Metacon. The latter, which specialises in the development and manufacturing of energy systems for fossil-free ’green’ hydrogen production, holds a 35% stake in Pherousa.

Pherousa has engaged with cargo owners who face increasing pressure to decarbonise their operations. The vessels are specifically designed for the copper industry, with Pherousa’s subsidiary, Pherousa Shipping, collaborating closely with two major copper miners during the Ultramax vessel’s design process. Their goal is to optimise the vessel’s layout for emissions-free transport of copper concentrates from extraction sites to smelters.

Ammonia cracking benefits

Pherousa’s patented ammonia cracking technology is designed to efficiently convert ammonia into high-quality hydrogen fuel. The company emphasises its versatility, highlighting the technology can supply hydrogen to PEM fuel cells, serve as a pilot fuel in ammonia-fuelled internal combustion engines (ICEs), and power hydrogen-fuelled ICEs.

DNV vice president and global business director for bulk carriers, Morten Løvstad noted ammonia cracking combined with a PEM fuel cell eliminates the need for pilot fuel or other fossil sources.

Furthermore, ABS director, global sustainability, Stergios Stamopoulos emphasised efficiency in ammonia cracking will be a decisive factor in its ability to contribute to the shipping industry’s decarbonisation efforts.

Sign up for Riviera’s series of technical and operational webinars and conferences:

- Register to attend by visiting our events page.

- Watch recordings from all of our webinars in the webinar library.

Related to this Story

Women in Maritime Today: Elin Saltkjel says no day working in maritime is dull

Events

Maritime Environmental Protection Webinar Week

Cyber & Vessel Security Webinar Week

The illusion of safety: what we're getting wrong about crews, tech, and fatigue

Responsible Ship Recycling Forum 2025

© 2024 Riviera Maritime Media Ltd.