Business Sectors

Events

Contents

Register to read more articles.

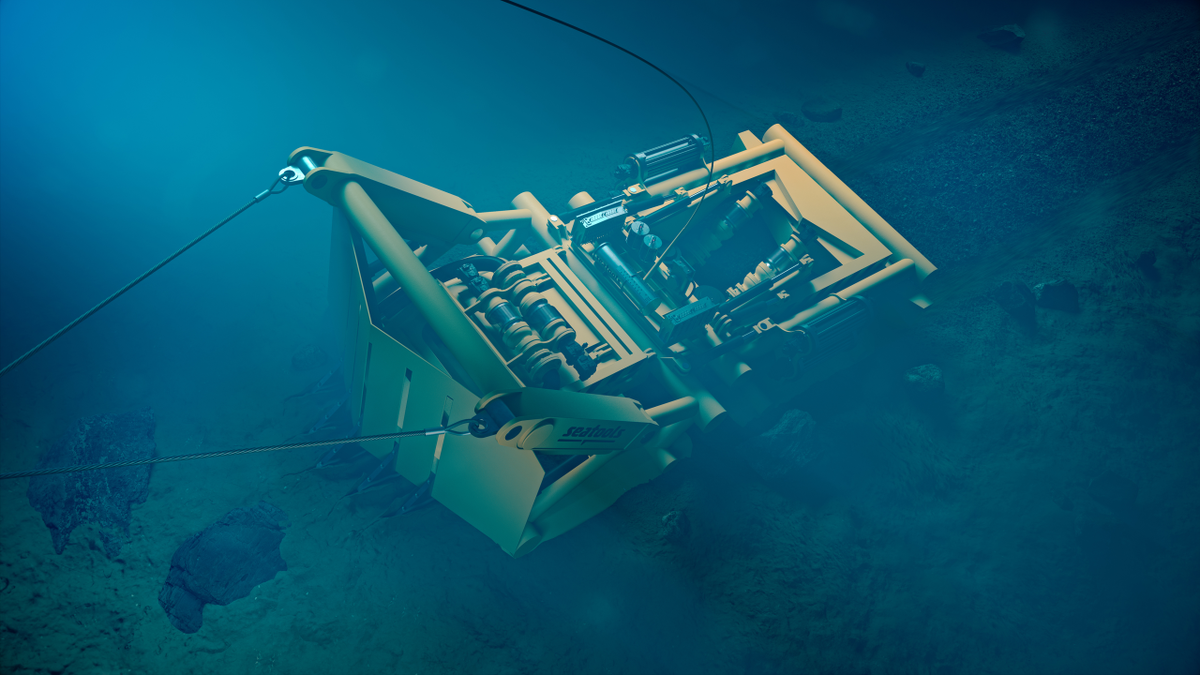

‘Iron Bull’ removes sub-surface objects that could obstruct cable-laying

The Netherlands-based Seatools has unveiled a powerful new seabed precutting and clearance system, known as ‘Iron Bull’

The company said the patented technology in Iron Bull “mitigates risks posed by adverse soil conditions and subsurface obstacles, offering offshore wind developers and contractors significant reductions in both risks and costs during offshore cable installation operations.”

The technology removes sub-surface objects, such as boulders and obsolete cables, which could obstruct cable-laying and burial operations. It also loosens the soil through precutting with what the company described as “unique drum-cutting technology.”

By fully clearing and loosening the cable trajectory over a breadth of 4 m, productivity, predictability and accuracy in achieving required burial depths for subsequent cable operations are significantly enhanced, the company claims.

“These improvements will lead to substantial cost reductions due to shorter cable burial times and higher success rates meeting required burial depths, reducing the need for extra unplanned protection work such as subsea rock installations,” Seatools said.

“Apart from cost benefits, seabed preconditioning and comprehensive soil data collection during initial offshore windfarm construction ensure a more reliable construction schedule. Achieving required burial depths directly minimises cable manipulation during installation, reducing the risk of cable damage, which is critical since mechanical loads cause about 50% of subsea power cable failures.”

The technology includes a 2-MW towed sledge, comparable in size and weight to a typical cable plough, incorporating robust and proven dredging technology. Jet-assisted rippers at the front remove large obstructions like boulders.

The hydraulically tiltable rippers can exert what Seatools described as ‘immense break-out forces’ on objects in the seabed, eliminating the need for the use of vessels with high bollard pull capacities that would otherwise be required by conventional tools that rely solely on towing forces to remove obstructions.

“The tool also has twin counter-rotating drum cutters to transform any type of soil into loose, eventually jet-able material,” said the company. “The drum cutters, equipped with Seatools’ proprietary jet assistance technology, prevent clogging even in the stickiest clay materials. Aft rippers remove any remaining small objects, ensuring the seabed is prepared for efficient and effective cable burial by standard jet trenchers.”

The technology was developed in partnership with Bruno Tack, founder of Innovate2dredge. With more than 30 years of experience and numerous patents in the field of dredging difficult soils, Mr Tack is an expert in troubleshooting, production improvement and the development of dredging processes and equipment.

Seatools said it is actively advancing the technology and engaging with stakeholders, including developers and partners, to further its development and application. The aim is to collaboratively refine, develop and commercialise the technology, targeting market introduction by 2027.

Riviera’s Offshore Wind Webinar Week will be held 4 November 2024. Click here to register for this free-to-attend event.

Related to this Story

Events

Offshore Support Journal Conference, Americas 2025

LNG Shipping & Terminals Conference 2025

Vessel Optimisation Webinar Week

© 2024 Riviera Maritime Media Ltd.