Business Sectors

Events

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

Contents

UPDATED: MHO-Co creates hybrid CTV design for Ørsted’s Hornsea 2 project

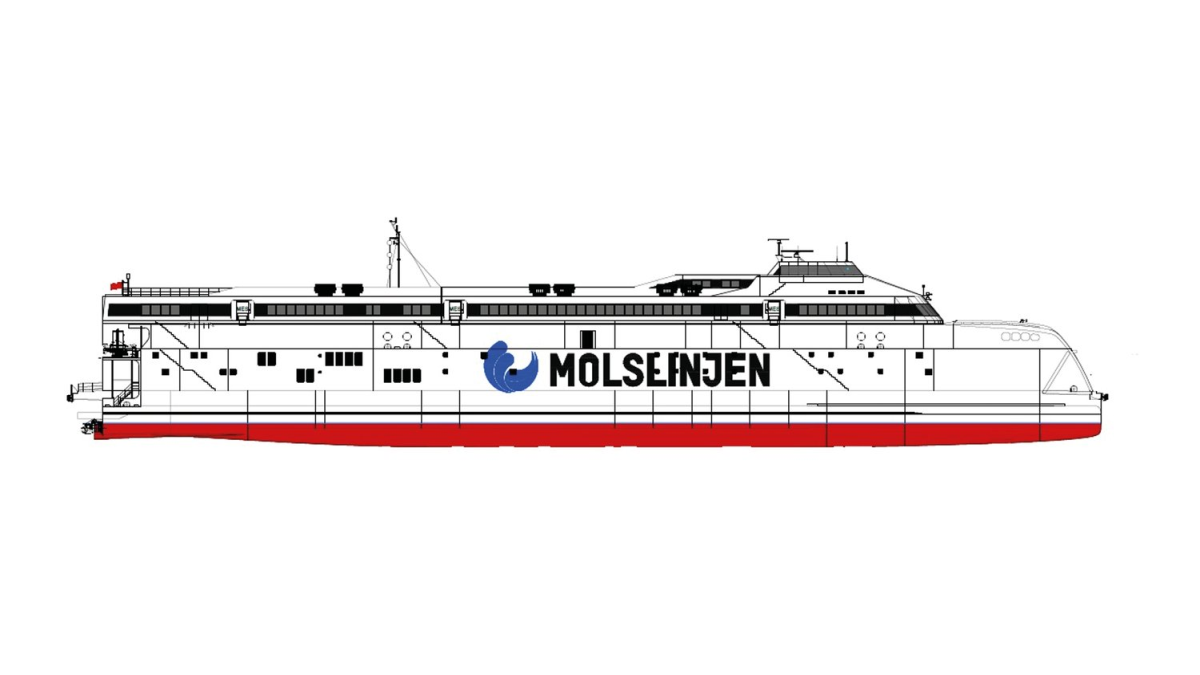

Danish shipping company MHO-Co is to build two hybrid crew transfer vessels with catamaran hullforms for Ørsted’s Hornsea 2 offshore windfarm in the UK. The innovative vessels will be propelled by electric motors that will help to reduce emissions

The 35-m CTVs will also be designed for but not with other environmentally friendly technology.

They are due to be launched mid-2021 and are to be bult at Afai Southern Shipyard in Guangzhou, a yard that specialises in developing, designing and constructing high-performance aluminium vessels.

MHO-Co founder and chief executive Mik Henriksen said, “Designing and building hybrid CTVs is a huge step in the environmental direction, and I am proud we at MHO-Co have found partners who share our vision for sustainable development in the offshore wind industry.” He said the new CTVs would be among the largest of their type.

The vessels’ newly-developed hybrid propulsion packages are designed in a way that enables them to be adapted at a later stage to eco-friendly power-generating techniques such as fuel cells.

MHO-Co partnered with Incat Crowther, which specialises in designing catamarans, for the vessels.

Incat Crowther Europe managing director Ed Dudson said, “MHO-Co always push the boundaries when it comes to new vessels in the offshore wind Industry.”

The vessels will use a combination of direct drive and electric propulsion for maximum flexibility and redundancy. Incat Crowther said this would result in a reduction in emissions across a range of operating modes, including a zero-emission mode.

The designer also confirmed that the newly-developed hybrid propulsion packages are designed in a way which enables them to be adapted at a later stage to eco-friendly power generation technologies such as hydrogen.

MHO-Co has chosen to install Danfoss’ ‘Editron’ propulsion system on the catamarans. The system’s permanent magnet electric motor will reduce weight and space on the CTV compared to conventional machinery, enabling the vessels to consume less fuel and enhancing efficiency, MHO-Co claimed.

Danfoss Editron marine business line director Erno Tenhunen said, “Our DC-grid hybrid propulsion technology is revolutionary and is highly flexible and easy to manage. It is benefits such as these that are allowing shipowners and operators to benefit from lower costs and longer operational lifetimes, without compromising on customer experience.” Using electric motors will significantly reduce CO2 emissions from the CTVs, he noted.

Both of the CTVs will be equipped with an Editron hybrid system consisting of four propulsion motors. The systems will also include DC-DC converters for the vessels’ batteries. The vessels will be capable of operating in either fully-electric or hybrid mode, and will have significantly reduced CO2 emissions compared to conventional diesel-powered vessels.

Mr Tenhunen said, “Previously, electric motors and components were too big for CTVs. Our compact and lightweight technology has overcome this issue, and solved the challenge faced by vessel designers, shipyards and end customers. Our Editron system is suitable for use in a limited space and allows for flexibility on battery selection, system concepts and machinery room design.”

The Incat Crowther 35 design will have a length overall of 34.3 m, waterline length of 33.3 m, beam of 11.0 m and draft (hull) of 1.45 m (prop 2.05 m).

Constructed from marine grade aluminium, they will be capable of transporting 24 windfarm technicians plus eight crew and will have a maximum speed of 25 knots.

A specification provided by Incat Crowther said the innovative CTVs will have a pair of Volvo Penta D13 main engines, each of 515 kW at 2,250 rpm. The hybrid system takes the form of two Danfoss EM-PMIs of 550 kW. There will also be five Danfoss EM-PMI Volvo D8 generators of 230 kW each at 1,900 rpm. The propulsors take the form of a quartet of Volvo IPS 30 pods. A 78 kWH battery pack from Corvus will also be fitted.

Operating under the Danish flag, the vessels will be classed by DNV GL, and bear the class notation DNV-GL 1A HSLC Crew Windfarm R.

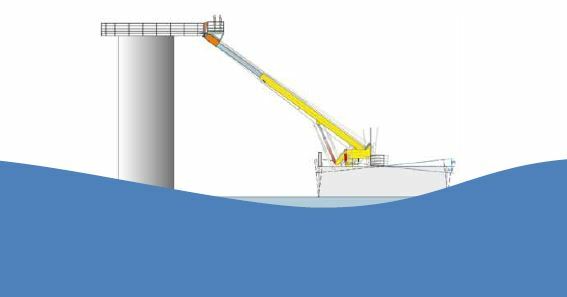

In another first, the CTVs will also be designed for installation of the Z-bridge ‘bring-to-work’ system, which would be installed on the forward deck.

This fully motion-compensated offshore access system will allow safe transfer of up to six persons and cargo from the vessel’s deck to offshore structures.

Because the Z-bridge lifts windfarm technicians from the deck of a vessel directly to the platform on a wind turbine it eliminates climbing, and will increase workability and improve the transfer time.

Mr Henriksen said he has experience of working with Afai Southern Shipyard on two of Incat Crowther’s K50 ferries, which his company used to manage. The contract for the two new vessels was signed in collaboration with shipbroker Pan Ocean Marine.

Riviera is hosting a week of free to attend 45-minute webinars focused on marine fuels commencing 29 June. Register your interest now

Related to this Story

Events

Maritime Regulations Webinar Week

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

© 2024 Riviera Maritime Media Ltd.