Business Sectors

Events

Contents

Bourbon to invest €75M to upgrade fleet IT

French shipowner Bourbon plans to upgrade a fleet of 132 offshore support vessels with remotely-monitored DP and better connectivity

French offshore support vessel operator Bourbon Corp will invest €75M (US$92M) to upgrade a fleet of 132 ships into smart ships, starting this year. This three-year investment is part of Bourbon’s strategy to split its huge fleet into those that can be improved with better connectivity and remote monitoring and a division that holds 65 vessels that are too old to have their IT updated.

This corporate strategy will involve restructuring the entire organisation into three distinct affiliates – Bourbon Marine & Logistics, Bourbon Subsea Services and Bourbon Mobility. This will be completed this year in reaction to falling demand for ageing platform supply vessels and growing requirements for Bourbon to capitalise on digitalisation by creating a smart fleet of modern supply vessels.

Bourbon then expects to dispose of the oldest 41 non-smart vessels (leaving 24 still operating) and expects this will result in an impairment loss of around €170M in its 2017 financial statements. The 132 vessels that Bourbon Marine & Logistics is upgrading will receive improvements to VSAT connectivity and bridge systems.

Part of this investment will involve upgrading vessel dynamic positioning (DP) for more automated control and remote monitoring. Bourbon vice president of operation standards and innovation Frederic Moulin spoke exclusively to Marine Electronics & Communications about these plans and the benefits.

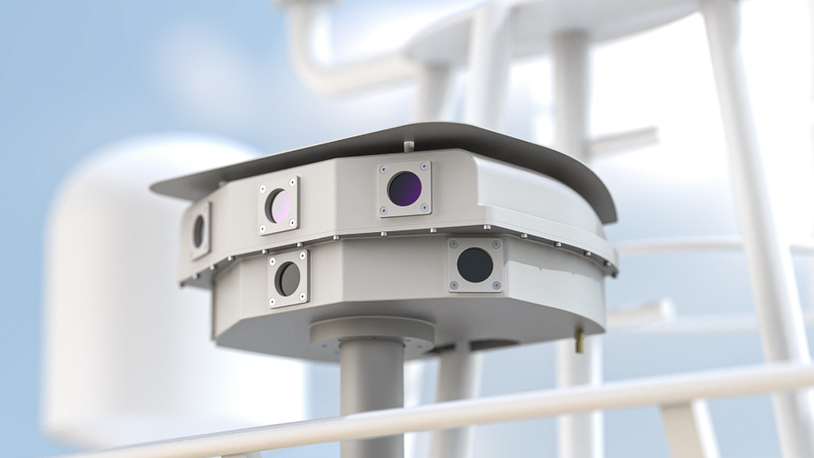

Bourbon worked with class society Bureau Veritas, technology supplier Kongsberg Maritime and Airbus subsidiary Apsys on a DP remote monitoring pilot project using platform supply vessel (PSV) Bourbon Explorer 508, Mr Moulin explained. This involved updating Kongsberg DP systems on this PSV for remote monitoring and verifying DP operations.

This pilot project, which started this year, is being conducted while the 3,600 dwt vessel operates on a long-term charter to BP in Trinidad, where it is supplying cargo to gas platforms that supply the Atlantic LNG production centre. Mr Moulin said the “payback from this investment is at least one year and Bourbon Explorer 508 is on contract until 2019.”

This monitoring technology was developed by Kongsberg Maritime. It collects data from the DP system that can be used on board and by onshore support teams to improve DP operations. Mr Moulin expects this to improve safety and reduce fuel and DP maintenance costs, adding that “remote monitoring will become an automatic function of DP.”

Apsys is helping the partners to identify and mitigate cyber security risks linked to data collection and communication between Bourbon’s vessels and onshore infrastructure. “It is important to ensure that the protocols for data transmission and remote access are secure,” said Mr Moulin. Apsys will also help Bureau Veritas create certification and class notations covering cyber security.

“It is important to ensure that the protocols for data transmission and remote access are secure”

Kongsberg provided a Master DP2 control system, which is linked to two 2,000 kW azimuthing Z-drive thrusters with fixed pitch propellers and two 1,000 kW controllable pitch bow thrusters.

Bourbon also invested in the people that will be using this upgraded DP to teach and test them on the new procedures, said Mr Moulin. One of the benefits of this upgrade for remote monitoring is that Bourbon can train up bridge officers instead of hiring specialised DP operators. “Our bridge engineer goes through DP training and gains sea time,” he explained.

Other benefits to Bourbon from DP monitoring includes using the collected data as an advisory tool for DP management to “optimise DP configuration for the best fuel consumption.” Mr Moulin continued: “We have been able to modify and upgrade bridge electronics with specialised systems for one engineer so we could eventually reduce crew by one person.”

It is important that DP can be handled by a bridge officer as Bourbon Explorer 508 spends around 8-10 hours, representing less than about 20% of a cargo run on DP . The rest of the time this PSV sails using its main engines and only does one or two cargo runs to BP platforms each week.

Mr Moulin stressed that DP monitoring is not in real-time and data transmissions to shore were in bandwidth-optimised packages over Bourbon Explorer 508’s VSAT satellite communications. This is managed by Inmarsat over Ku-band and with FleetBroadband L-band for back-up. This provides this 79 m PSV with bandwidth of 512 kbps, which Mr Moulin said was sufficient to meet data transmission requirements and crew welfare services.

Fleet-wide upgrades

With this pilot test underway, Bourbon is considering how to replicate this technology on other vessels. “We are looking to convert Bourbon Explorer 508’s sister ships,” he said, of which there are 20, operating in Africa, Caribbean and Asia. “Eventually we could have more vessels with DP monitoring,” said Mr Moulin.

During the pilot project and the first of these vessel upgrades, DP is, and will be, monitored 24 hours a day in Kongsberg Maritime’s offices in Norway. However, as more vessels are added to the programme, Bourbon will “reach a critical size and we can remotely watch DP on our vessels ourselves,” he explained. “We are planning to build a remote monitoring centre; it is yet to be decided where.”

“We are planning to build a remote monitoring centre”

Once this facility is built, Bourbon intends to extend its remote management capabilities to monitor engineroom machinery and maintain bridge systems. “We see opportunities to support crew with task control, advice and processing and for planned maintenance monitoring.”

A matter of class

Conversion of the fleet will involve replacing the bridge and DP hardware and reassessing class with perhaps new notations. “Bureau Veritas provides us with support and regulatory analysis as we need to present to flag states and clients and ensure that it meets regulatory requirements,” said Mr Moulin.

Bureau Veritas global market leader for tugs and offshore support vessels Eva Peño told MEC that the agreement with Bourbon was just the beginning of digitalisation of offshore support vessels. “The aim of this smart shipping programme is to develop and deploy automation and real-time fleet monitoring applications,” she said. This is “to optimise the safety and reliability of vessel operations and reduce operating expenditure.”

Ms Peño believes that expansion of computerised control systems and increasing levels of connectivity is pushing shipping towards operating autonomous vessels, including tugs and fire-fighting vessels.

Bureau Veritas published guidelines for autonomous shipping in December 2017* to support and assist shipyards and owners to enhance the autonomy of vessels. It is probable that autonomous offshore vessels and tugs will be developed in the future. “Tugs are a vessel type whose function, operational parameters and cost base may be well suited to autonomous operations,” said Ms Peño. “At Bureau Veritas we are ready to take it to the next level.”

*To read Bureau Veritas’ guidelines for autonomous shipping, use this link http://bit.ly/MEC_BVauto

Bourbon Explorer 508 particulars

Built: 2014

Type: Medium PSV

Operations: Trinidad

Charterer: BP to 2019

Flag: France

Class: Bureau Veritas

Deadweight: 3,600 dwt

Length oa: 79 m

Depth: 7.8 m

Top speed: 14.2 knots

DP: Kongsberg Master DP2

Sensors: 3 DGPS, 1 radius

Main propulsion: 2x 2,000 kW azimuth Z-drive FPP

Bow thrusters: 2x 1,000 kW CPP

Cargo deck: 720 m2

Related to this Story

Events

TUGTECHNOLOGY '25

Reefer container market outlook: Trade disruption, demand shifts & the role of technology

Asia Maritime & Offshore Webinar Week 2025

Marine Lubricants Webinar Week 2025

© 2024 Riviera Maritime Media Ltd.