Business Sectors

Events

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

Contents

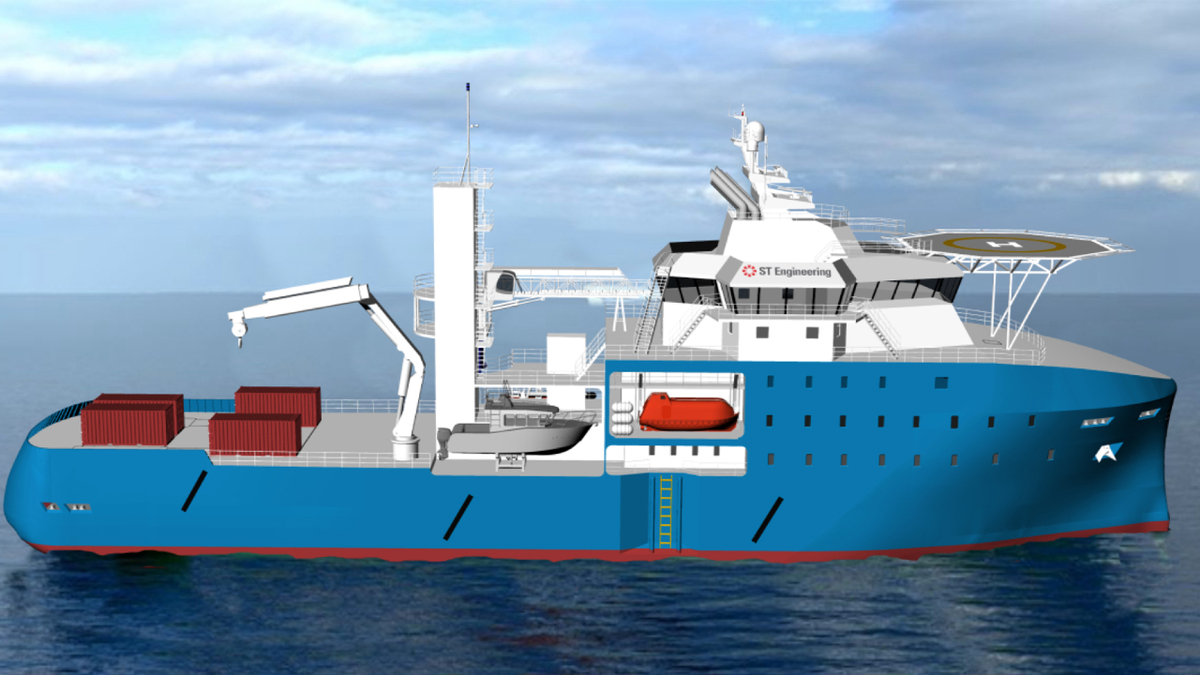

Fitted with batteries, SOV design targets US offshore wind market

With the US offshore wind market heating up, several new designs for service operation vessels (SOVs) have been unveiled from shipbuilders, including one from Singapore’s ST Engineering that will have batteries and built-in condition-based maintenance.

The marine arm of Singapore’s ST Engineering has developed the SOV design with an energy storage system based on its Eco-hull for low fuel consumption and enhanced seakeeping characteristics to maximise crew comfort of the crew, service personnel and specialists.

Configured with two azimuth-type main propulsion propellers, two tunnel bow thrusters and one retractable azimuth forward thruster, the SOV is dynamic positioning class 2 capable (DP2) with a heave-compensated gangway. This combination will allow the SOV to safely transfer personnel from onboard to service offshore wind turbines. Additionally, a cargo/passenger lift with six fixed levels provides zero-step access-and-transfer for the technician and cargo from the vessel to the turbine’s transition piece (TP) through the gangway.

Among the other onboard equipment is a 3D-motion compensated knuckle boom crane to provide covering access to TP and the operational areas for boat landings. The SOV has a large clear space for deck preparation and is fitted with a container skidding system, suitable for up to 20 ft (6 m) containers.

For the comfort of crew and personnel, ST Engineering said special attention has been paid to the noise and vibration characteristics in its design, with a ‘5-star hotel’ standard interior design and customisable facilities. The vessel can accommodate up to 85 service personnel and crew for servicing the offshore windfarms.

To maximise operational efficiency and reduce any unplanned downtime, ST Engineering has integrated NERVA ship management and sense-making systems (NERVA SMS2). The ABS-certified NERVA SMS2 adopts data analytics and machine learning techniques to perform predictive maintenance and condition-based monitoring of the equipment, providing prescriptive and pre-emptive data to operators for better decision making.

“Having identified the renewables segment as well-suited to ST Engineering’s capabilities, the SOV concept is targeted at operators looking for a more cost-effective and reliable engineering solution that can be customised,” said ST Engineering senior manager Phoebe Lim. “ST Engineering can cater to the needs of global developers and operators, so the construction is available out of both Singapore and US shipyards,” she said.

Change at the top at VT Halter

No US shipyard as yet has built an SOV, but ST Engineering’s US shipyard, VT Halter Marine in Pascagoula, Mississippi, has a long history of constructing vessels for the offshore oil and gas market. Most recently, VT Halter Marine has secured contracts to build the first LNG bunker articulated tug barge (ATB) for Q-LNG for the US, US Navy berthing barges and the US Coast Guard Polar Security Cutter (PSC).

The Mississippi shipyard recently shook up its leadership, naming Robert Merchant president and chief executive, replacing Ron Baczkowski, who held the position since 2018.

Much of Mr Merchant’s career was spent at Ingalls Shipbuilding in Pascagoula, spending almost five years as vice president.

Mr Merchent has a Bachelor’s of Science in business management from the University of Southern Mississippi, with certificates on executive leadership from the Harvard Business School, executive finance from the Wharton School of Business and executive marketing from the University of Maryland.

Related to this Story

Events

Maritime Regulations Webinar Week

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

© 2024 Riviera Maritime Media Ltd.