Business Sectors

Events

Offshore Wind Webinar Week

Contents

Register to read more articles.

Torsional vibration analysis: minimising downtime, maximising hybrid efficiency

The growing adoption of hybrid propulsion systems in marine vessels introduces new complexities to drivetrain design and operation, making torsional vibration analysis (TVA) more critical than ever

This was the key message from a November Riviera webinar held in association with Regal Rexnord, titled Hybridisation, Electrification & The Vital Role of Torsional Vibration Analysis.

The webinar featured Regal Rexnord industry manager for marine and power generation Bob Lennon and the company’s director of research and development for couplings, Dr Mahamudul Hasan. Their combined expertise provided attendees with valuable insights into ensuring that selected flexible couplings and intermediate drive shafts are optimised for vessel operation. This optimisation is essential to prevent costly downtime resulting from torsional vibration issues.

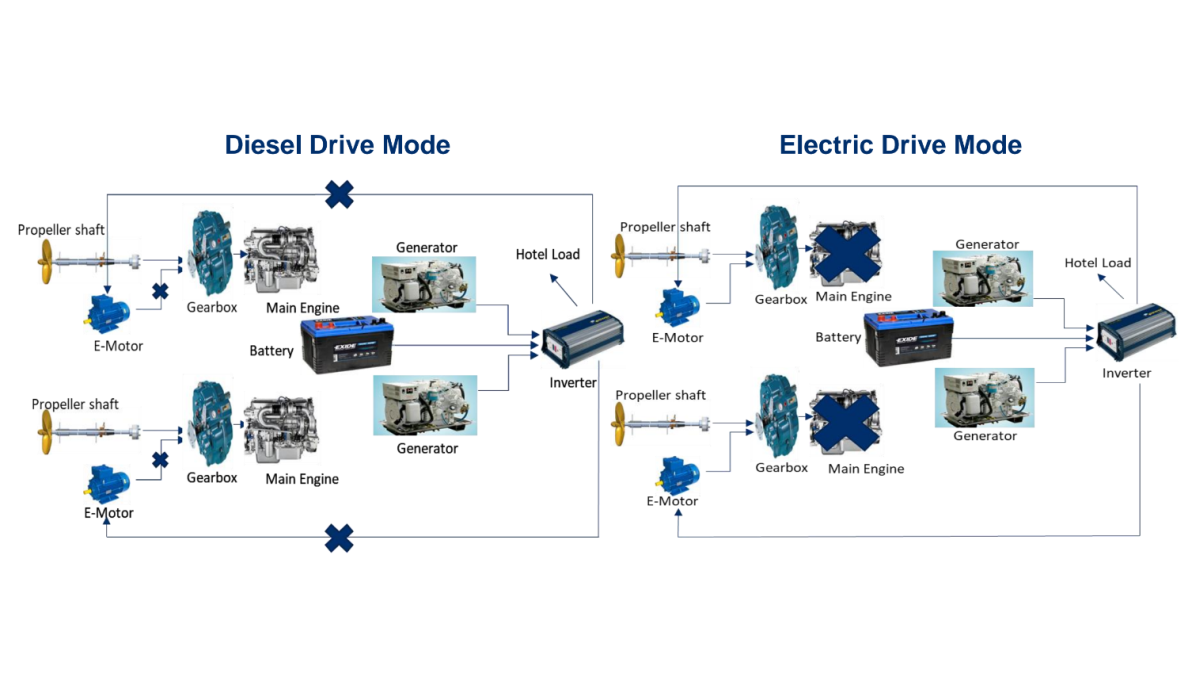

The experts discussed four distinct operating modes found in hybrid systems. In diesel drive mode, the diesel engine propels the vessel while the hotel load is managed by the main generator or battery. During electric drive mode, the diesel engine is off, allowing the electric motor to provide propulsion while hotel loads remain powered by the generator or battery. In boost mode, both the diesel engine and electric motor work together to provide propulsion, with hotel loads still managed by the generator or battery. Finally, in generator mode, the diesel engine powers propulsion while the electric motor acts as a generator, supplying power for additional loads or charging batteries.

Dr Hasan emphasised that each mode presents unique vibration characteristics. He noted when both combustion engines are active, there is an increase in excitation due to the torsional vibration signature of both engines. This highlights the importance of thorough analysis during the design phase to ensure optimal performance across all operating conditions.

He went on to highlight three distinct but related challenges.

The first major challenge centres on the complexity of managing multiple power sources and operating modes. Each transition between modes creates distinct vibration patterns and stresses on drivetrain components. When both engines are active, the combined torsional vibration signatures create more complex excitation patterns than single-engine operation, requiring comprehensive analysis and careful component selection.

The second critical challenge involves managing the system’s natural frequencies. Each operating condition results in changes to the natural frequencies of the system, impacting the overall torsional vibration response. For example, when the electric motor is switched off, the mass-elastic system changes, potentially shifting the first natural frequency to a different coupling or system component.

The third major challenge focuses on data accuracy for TVA calculations. Dr Hasan emphasised repeatedly, "The more accurate the data, the better results we will provide".

Regal Rexnord has developed sophisticated processes for establishing time-dependent power loss values, particularly crucial in hybrid applications where allowable limits may be exceeded. Its approach combines test bench measurements at specific frequencies and torques with calibrated simulation models to capture comprehensive time-dependent power loss data.

The experts presented several innovative approaches to address these challenges. Early engagement of TVA specialists emerged as crucial, with Mr Lennon emphasising the importance of expert involvement during initial design phases. Regal Rexnord’s approach includes analysing multiple operational conditions within a single simulation model, reducing computation time and enabling faster results.

The discussion also highlighted tailored coupling and shaft solutions, including optimised coupling stiffness, lightweight composite shafts and strategically placed middle masses to mitigate harmful vibrations. These solutions prove most effective when validated through comprehensive sea trial measurements, where instrumented rotating equipment provides real-world performance data to compare against TVA predictions.

The Q&A session revealed several ongoing debates and concerns. Questions about coupling lifetime predictions and maintenance intervals prompted detailed responses. Mr Lennon explained that while ideal conditions might yield a 10-year or 50,000-hour lifespan for natural rubber components, factors such as misalignment, oil exposure and system upsets can significantly impact longevity.

The debate between transient versus harmonic analysis also sparked animated technical discussion. Dr Hasan explained that while transient analysis might seem preferable, the continuous nature of marine operations often makes harmonic analysis more practical, particularly when considering the various operating modes and hotel loads in hybrid systems.

Poll results revealed significant insights into current industry practices. Only 44% perform full system multi-mass TVA during early design stages, while 65% engage vibration specialists for sea trials. 48% report only a basic understanding of torsional vibration’s influence on marine propulsion drivetrains. Regarding propulsion preferences, 33% favour electric drive systems, 28% prefer parallel hybrid configurations and 30% consider alternative fuel solutions.

With alternative fuels and variable compression combustion engines on the horizon, Mr Lennon highlighted the increasing role of data capture and predictive analysis, referencing Regal Rexnord’s development of its ’Perceptive’ technology for real-time torque and vibration monitoring.

The speakers also emphasised that reducing vibrations contributes directly to sustainability goals by minimising environmental impact, with Dr Hasan highlighting that torsional vibration analysis will remain crucial for developing new technologies and ensuring reliable, efficient marine propulsion systems.

Panellists Regal Rexnord director of research and development for couplings, Dr Mahamudul Hasan and industry manager for marine and power generation Bob Lennon

Related to this Story

Events

Offshore Wind Webinar Week

Maritime Decarbonisation, Europe: Conference, Awards & Exhibition 2025

Offshore Support Journal Conference, Americas 2025

© 2024 Riviera Maritime Media Ltd.