Business Sectors

Contents

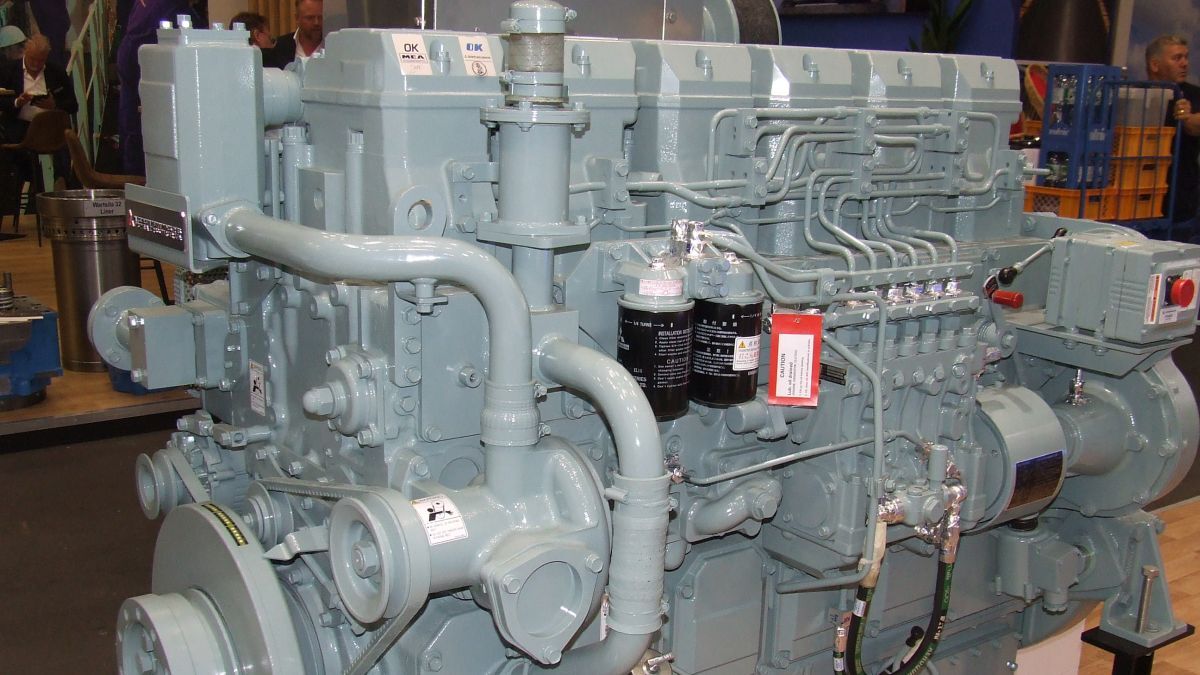

OEMs develop methanol and hydrogen workboat engines

Manufacturers of main propulsion engines and generator sets are developing products capable of burning methanol and hydrogen in response to tightening green regulations

Manufacturers are developing and testing engines for combusting methanol and hydrogen for port, coastal and inland vessel applications, as demand for operating in stringent environmental regimes rises.

Moteurs Baudouin is developing methanol-fuelled engines for tugs, workboats, offshore support vessels, ferries and shortsea shipping. It is also in a strong position to explore hydrogen-powered engines and fuel cells through partnerships with companies in the Weichai Group.

The French original engine manufacturer (OEM) has expanded its range of diesel-fuelled combustion engines for high horsepower applications, especially for tugs and towing vessels, and is developing low-emissions solutions for the next generation of port and offshore vessels.

The Cassis, France-headquartered OEM is developing methanol-combusting engines. It already offers engines compliant with hydrogenated vegetable oil (HVO) biofuel, which is increasingly used in tugboats in Europe and North America, such as its 16-cylinder M33.3, 8F21 and 12M55 engines.

In the more immediate term, Moteurs Baudouin’s research and development team is working diligently on the certification process for propulsion engines and marine gensets with environmental regulators at IMO, Europe and in North America.

Its engines can be connected to compact selective catalytic reduction (SCR) systems to minimise NOx emissions to comply with IMO Tier III and US Environmental Protection Agency (EPA) emissions standards.

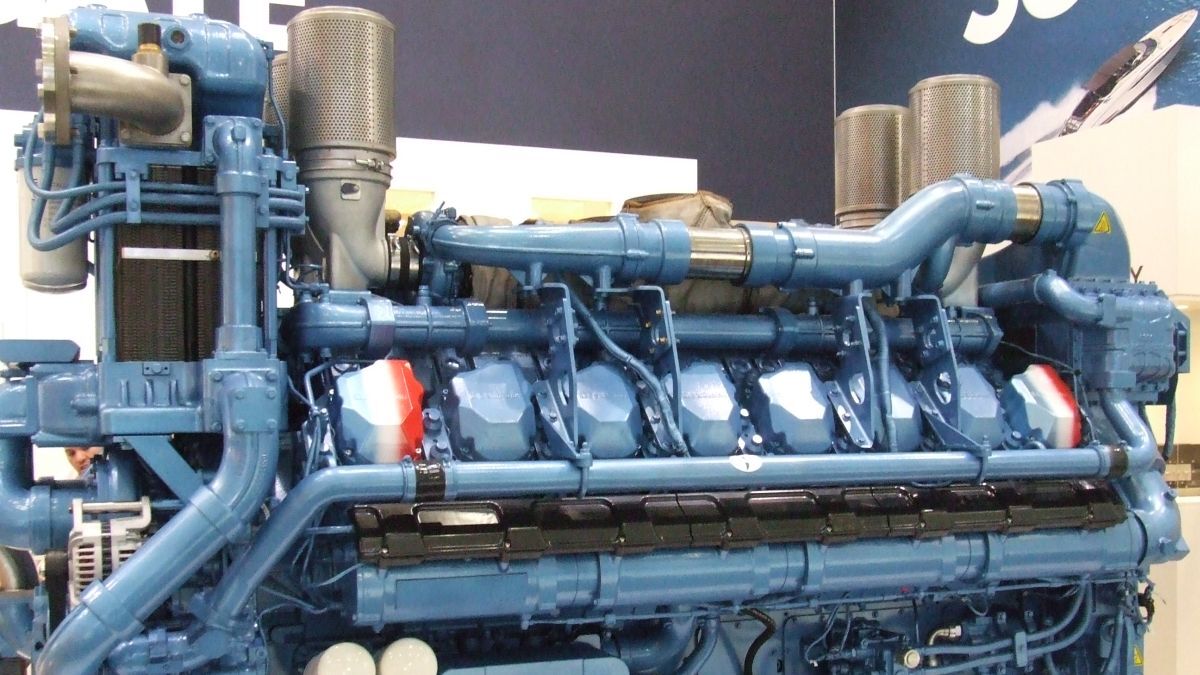

Baudouin introduced its 12M55 main propulsion engine at Riviera’s 27th International Tug & Salvage (ITS) Convention & Exhibition in Dubai, UAE, on 21-23 May 2024. This was designed purely for marine applications with individual cylinder heads and inspection hatches to simplify maintenance even in small enginerooms.

A 12M55 engine incorporates an electronically controlled common rail system and has 12 cylinders in V formation, a bore of 180 mm and stroke of 215 mm, a total displacement of 66 litres and an idle speed of 600 rpm.

This range has a rated power of 1,800 kW at 1,600 rpm to 2,536 kW at 1,800 rpm for IMO Tier II compliance. It can be Tier III compliant with an SCR. The 12M55 engine is ready, and certified by Bureau Veritas, for combusting HVO.

During the SMM exhibition in Hamburg, Germany, in September 2024, Baudouin unveiled its new M33.3 range of marine propulsion engines, including 6 and 16-cylinder models, plus it revealed the 8F21, an 8-cylinder marine propulsion engine with common rail technology, which Mr Choos says ensures optimum precision in fuel delivery for efficient performance.

Baudouin’s recent engine deliveries include several 12M26.3 Tier III engines for a series of tugs built by Sanmar Shipyard in Turkey, and 12M55 model engines for four tugboats built by Bogazici Shipyard.

Development partnerships

Mitsubishi Heavy Industries (MHI) is developing dual-fuel and single-fuel versions of its 25-30 litre engines for large tugs, workboats, offshore support and inland vessels. These developments, in partnership with Koedood and Storm Group’s ScanDiesel, are aimed at gensets for vessels needing to comply with stringent environmental regulations, such as the European Union’s Stage V.

These partners are working on four projects, says Mitsubishi Turbocharger and Engine Europe general manager Morten Brix. For methanol, this involves developing and testing dual-fuel engines with Koedood and Storm, enabling the use of diesel until green fuels are ready.

“The single cylinder engine test cell was ready in July 2024 at MHI’s research facility in Japan, while the plant is building a multi-cylinder test engine in 2024,” says Mr Brix.

Another project with Koedood involves building and testing hydrogen-powered engines. This started with a single-cylinder engine “to get experience with how hydrogen performs with the engine,” explains Mr Brix. “With this data, we started building a multi-cylinder engine, which will be completed in July 2024.”

This will be calibrated in Q4 2024 and delivered to Koedood in December, ready to be included in a genset and installed on a vessel in 2025. It does not need any SCR as hydrogen goes in and water comes out. MHI is developing the engine control system.

In a third project, MHI is developing a dual-fuel hydrogen engine for a genset for installation on a vessel by 2025 as part of a green shipping initiative.

A fourth projects involves developing an LNG monofuel engine with DNV class and port-fuel injection. This engine was completed in Japan this year and MHI is working on the control and monitoring system.

Mr Brix says these will be used by vessels requiring low-emissions high-speed gensets able to burn diesel until green fuels are available. Power outputs of these engines would be 500-600 kW at three speeds, 1,200 rpm and 1,800 rpm for generating AC at 60 Hz and 1,500 rpm for 50 Hz. These could be applied as marine propulsion engines in tugs and workboats with four gensets in an electric propulsion system instead of two engines. Mitsubishi engines are already approved to use HVO fuel.

German OEM

MAN Engine has introduced a power-dense MAN D3872 engine, with a modular exhaust-gas aftertreatment system for EPA Tier 4 and IMO Tier III-compliant workboats. This 30-litre four-stroke engine has a significant increase in displacement compared with its well-proven, 24-litre MAN D2862 series, expanding its four-stroke portfolio to meet workboat applications that require additional power and torque.

At SMM, MAN first displayed the high-speed LE432 variant of the new series delivering 1,213 kW at 2,100 rpm for medium-duty applications.

Further power variants of the MAN D3872 for light-duty applications with 1,618 and 1,471 kW are also available, with additional engines in the series planned.

Based on a new engine platform that was inspired by the proven MAN D2862 V12 engine series, the new MAN D3872 engine has an injection pressure of 2,200 bar and the new MD1+ engine control unit to optimise the engine, resulting in low fuel consumption and emissions.

MAN Engine set out to develop high power density, and the most powerful variant, D3872 LE433, achieves an impressive 1,618 kW at a dry weight of just 2,720 kg. The engine designer was able to achieve this increase in power without going much beyond the footprint of the smaller 24-litre MAN D2862 V12 engine; at 2,335 mm, its length is just 100 mm longer than the D2862 and its connection dimensions are identical. This compact configuration lends itself to the tight constraints of workboat enginerooms.

Riviera’s TUGTECHNOLOGY ‘25 will be held in Antwerp, 22-23 May 2025. Click here for more information on this industry-leading event.

Related to this Story

Events

Offshore Support Journal Conference, Americas 2025

LNG Shipping & Terminals Conference 2025

Vessel Optimisation Webinar Week

© 2024 Riviera Maritime Media Ltd.