Business Sectors

Events

Contents

Register to read more articles.

To fulfil potential, onboard carbon capture must overcome engineering and regulatory hurdles

Once the regulatory landscape becomes clearer, DNV’s Jan Hagen Andersen sees a significant role for carbon capture and storage

Wide-scale availability, supply and infrastructure supporting low- and zero-carbon e-fuels meant to advance the decarbonisation of shipping are years away. To bridge this gap, some see onboard carbon capture and storage (CCS) technology as a means of reducing CO2 emissions from ships burning conventional fossil fuels.

But Jan Hagen Andersen, DNV business development director for the Americas, sees CCS playing an even more significant role in meeting overall global climate goals, not just those of shipping. And while CCS is already employed by many land-based industries, it will have to be scaled up even with the introduction of e-fuels.

“Hard-to-abate industries like cement and steelmaking do not have many options to use alternative fuels, so they will be producing CO2 in their production process,” he says. “The only way to lower their CO2 emissions is to capture it.”

Scaling up CCS encompasses two distinct maritime aspects. One is capturing and liquefying CO2 from an industrial source for transport, potentially by pipeline or tanker, for injection and storage in a depleted offshore oil and gas field or underground reservoir. The other is capturing, liquefying and storing CO2 from a ship’s emissions for offloading at a port.

While CCS has been in use on land for decades, engineers must overcome a host of new complexities when designing a shipboard system. Chief among these are space requirements for storing liquefied CO2 (LCO2) and the increase in a ship’s fuel consumption to operate the system.

“There is an energy penalty to capture CO2,” cautions Mr Andersen. In land-based applications, captured CO2 would most likely be kept as a gas and moved through pipeline. “You would not necessarily have to liquefy it and store it in pressure tanks like on ships. So that’s one level of added complexity,” he says.

Ship operators would also have to shoulder the added expense of storing the LCO2 onboard, reducing available cargo space, and offloading it at a port.

“There is an energy penalty to capture CO2”

Another consideration, says Mr Andersen says, is the need for a regulatory framework governing the system’s use and operation. Regulations would need to address CO2 storage on board, the location of storage tanks and the type of training required to maintain and operate an onboard CCS.

And while captured CO2 is currently viewed as a waste product, there is also the potential for its use in producing blue fuels, turning it into a commodity. This, too, requires the development of a regulatory framework.

As an example, Mr Andersen highlights a container vessel that captures CO2 and stores it on board as a cargo for sale. “Suddenly, this ship is a gas carrier, carrying CO2 as a cargo. This would create challenges for IMO, flag states and class to handle,” he says.

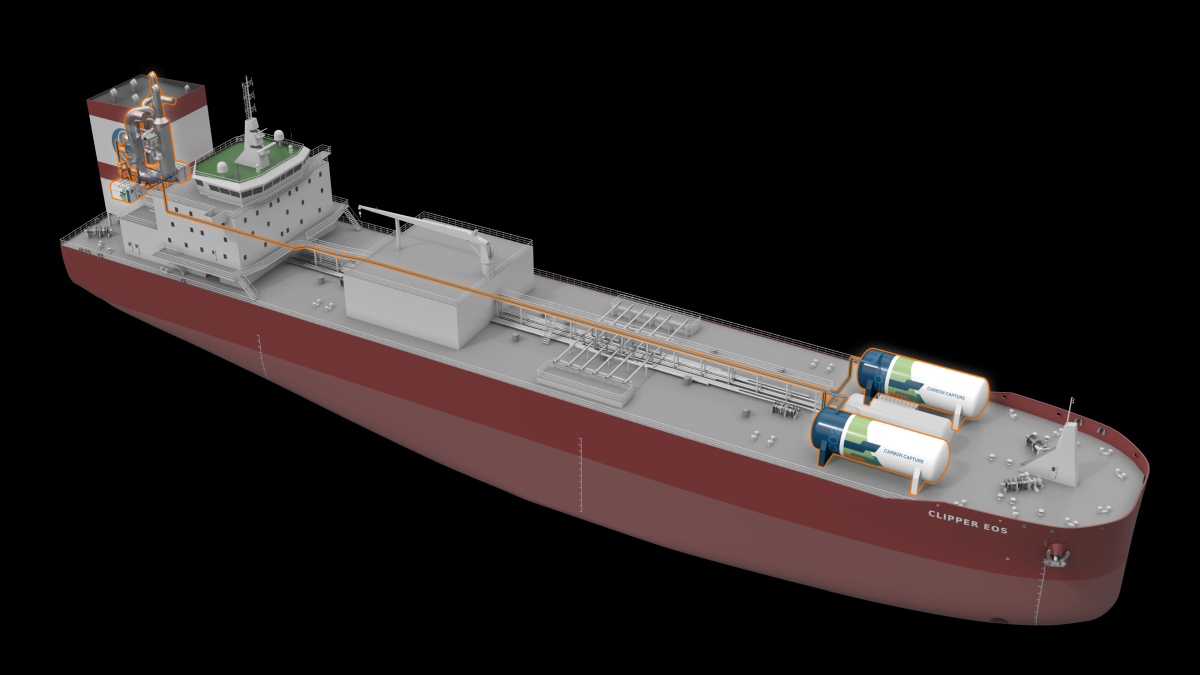

In one of the industry’s first full-scale pilots, DNV is collaborating with Norwegian shipowner Solvang and technology provider Wärtsilä to test an onboard CCS on the 21,000-m3 ethylene carrier Clipper Eos.

Clarity on onboard CCS will likely emerge when it becomes clearer how it will be handled commercially and regulated by IMO and the EU, says Mr Andersen. He sees the need for more pilots, more technology qualification and maybe some alignment of technology, with more widespread full-scale onboard systems installed in the late 2020s or early 2030s.

______________________________________________________________________________

Mr Andersen will discuss carbon capture and storage during a session at Maritime Decarbonization Conference, Americas, 14-15 December 2023. For more details on the programme and to register, please click here.

Related to this Story

Events

Maritime Environmental Protection Webinar Week

Cyber & Vessel Security Webinar Week

The illusion of safety: what we're getting wrong about crews, tech, and fatigue

Responsible Ship Recycling Forum 2025

© 2024 Riviera Maritime Media Ltd.